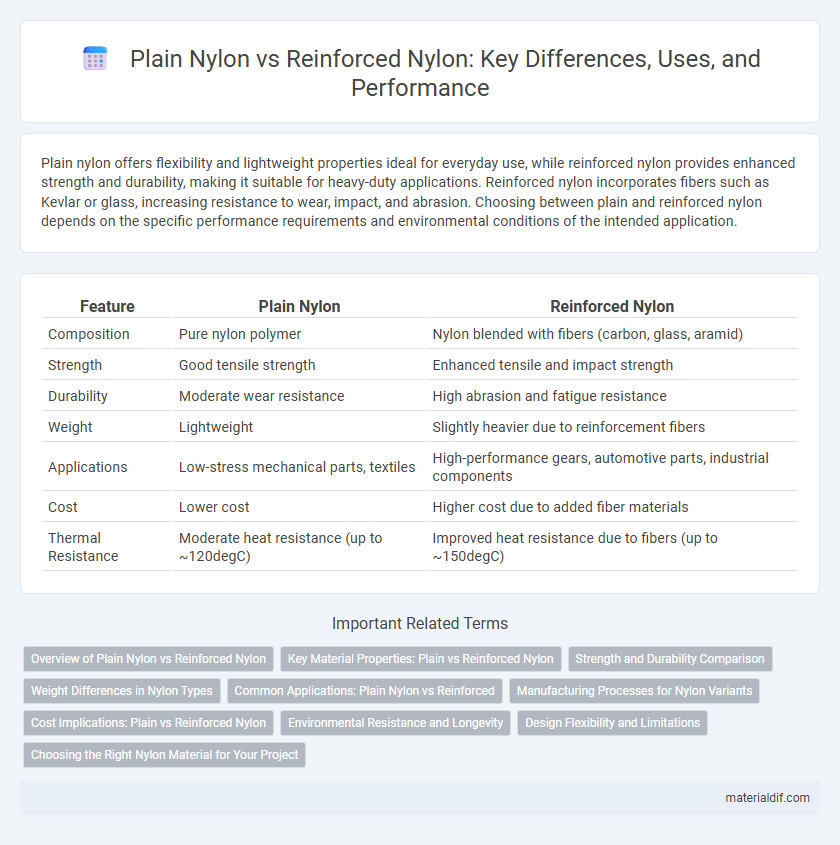

Plain nylon offers flexibility and lightweight properties ideal for everyday use, while reinforced nylon provides enhanced strength and durability, making it suitable for heavy-duty applications. Reinforced nylon incorporates fibers such as Kevlar or glass, increasing resistance to wear, impact, and abrasion. Choosing between plain and reinforced nylon depends on the specific performance requirements and environmental conditions of the intended application.

Table of Comparison

| Feature | Plain Nylon | Reinforced Nylon |

|---|---|---|

| Composition | Pure nylon polymer | Nylon blended with fibers (carbon, glass, aramid) |

| Strength | Good tensile strength | Enhanced tensile and impact strength |

| Durability | Moderate wear resistance | High abrasion and fatigue resistance |

| Weight | Lightweight | Slightly heavier due to reinforcement fibers |

| Applications | Low-stress mechanical parts, textiles | High-performance gears, automotive parts, industrial components |

| Cost | Lower cost | Higher cost due to added fiber materials |

| Thermal Resistance | Moderate heat resistance (up to ~120degC) | Improved heat resistance due to fibers (up to ~150degC) |

Overview of Plain Nylon vs Reinforced Nylon

Plain nylon consists of polyamide fibers known for high tensile strength, flexibility, and abrasion resistance, making it suitable for textiles and molded components. Reinforced nylon integrates additives like glass fibers or carbon fibers, significantly enhancing mechanical properties such as stiffness, dimensional stability, and impact resistance. This reinforcement allows reinforced nylon to perform better under higher stress conditions, ideal for automotive parts, industrial machinery, and structural applications.

Key Material Properties: Plain vs Reinforced Nylon

Plain nylon offers excellent flexibility, abrasion resistance, and chemical stability, making it suitable for lightweight applications. Reinforced nylon incorporates additives such as glass fibers or carbon fibers, significantly enhancing tensile strength, stiffness, and wear resistance for heavy-duty performance. The choice between plain and reinforced nylon depends on the required mechanical properties and environmental durability in specific industrial uses.

Strength and Durability Comparison

Plain nylon offers good tensile strength and flexibility, making it suitable for lightweight applications requiring moderate durability. Reinforced nylon, often embedded with glass fibers or carbon fibers, significantly enhances the material's strength, rigidity, and resistance to wear, ideal for high-stress environments. The inclusion of reinforcements reduces deformation and improves impact resistance, extending the lifespan of components under mechanical load.

Weight Differences in Nylon Types

Plain nylon typically has a lower density, resulting in a lighter material weight compared to reinforced nylon, which is embedded with additives like glass fibers to enhance strength and rigidity. Reinforced nylon's increased weight is attributable to these fillers, which can raise the density by up to 30-40%, making it more suitable for high-stress applications despite the additional weight. Weight differences significantly impact the choice between plain and reinforced nylon in industries such as automotive and aerospace, where material weight affects overall performance and fuel efficiency.

Common Applications: Plain Nylon vs Reinforced

Plain nylon is widely used in applications such as gears, bushings, and automotive components where moderate strength and wear resistance are sufficient. Reinforced nylon, typically enhanced with glass fibers or carbon, is preferred in high-performance industries including aerospace, industrial machinery, and structural components due to its superior tensile strength and dimensional stability. Choosing between plain and reinforced nylon depends on load requirements, operating environment, and durability needs, with reinforced variants excelling in heavy-duty and high-stress conditions.

Manufacturing Processes for Nylon Variants

Plain Nylon is typically manufactured through a straightforward extrusion or injection molding process, where the polymer is melted and shaped into desired forms, ensuring uniform molecular alignment for strength and flexibility. Reinforced Nylon incorporates additional materials such as glass fibers or carbon fibers during compounding, which are blended uniformly to enhance mechanical properties like tensile strength, stiffness, and heat resistance. The manufacturing process for reinforced Nylon requires precise control of fiber orientation and dispersion to optimize performance characteristics for demanding industrial applications.

Cost Implications: Plain vs Reinforced Nylon

Plain nylon offers a lower cost solution due to its simpler manufacturing process and reduced material usage, making it ideal for budget-conscious applications. Reinforced nylon incorporates materials such as glass fibers or carbon fibers, significantly increasing strength and durability but also driving up production costs by 30-50%. Evaluating cost implications requires balancing initial material expenses against long-term performance benefits in demanding environments.

Environmental Resistance and Longevity

Plain Nylon exhibits good flexibility and moderate environmental resistance but tends to absorb moisture, which can reduce its mechanical properties and lifespan when exposed to humid or wet conditions. Reinforced Nylon incorporates additives such as glass fibers or carbon fibers, significantly enhancing its strength, dimensional stability, and resistance to abrasion, chemicals, and UV radiation, resulting in superior longevity in harsh environments. The reinforced variant is ideal for applications requiring extended performance and durability, particularly in outdoor or chemically aggressive settings.

Design Flexibility and Limitations

Plain nylon offers high design flexibility with excellent moldability and impact resistance, making it suitable for intricate parts and lightweight applications. Reinforced nylon, typically filled with glass fibers or carbon, provides enhanced mechanical strength and rigidity but can limit design complexity due to increased material stiffness and potential wear on tooling. Choosing between plain and reinforced nylon depends on the balance needed between durability and the ability to incorporate fine details in the design.

Choosing the Right Nylon Material for Your Project

Plain nylon offers excellent flexibility, chemical resistance, and wear properties suited for lightweight, less demanding applications. Reinforced nylon, typically infused with glass fibers or other fillers, provides enhanced strength, stiffness, and dimensional stability, ideal for high-stress components and structural uses. Selecting the right nylon depends on balancing performance requirements such as tensile strength, impact resistance, and environmental factors to ensure durability and functionality in your project.

Plain Nylon vs Reinforced Nylon Infographic

materialdif.com

materialdif.com