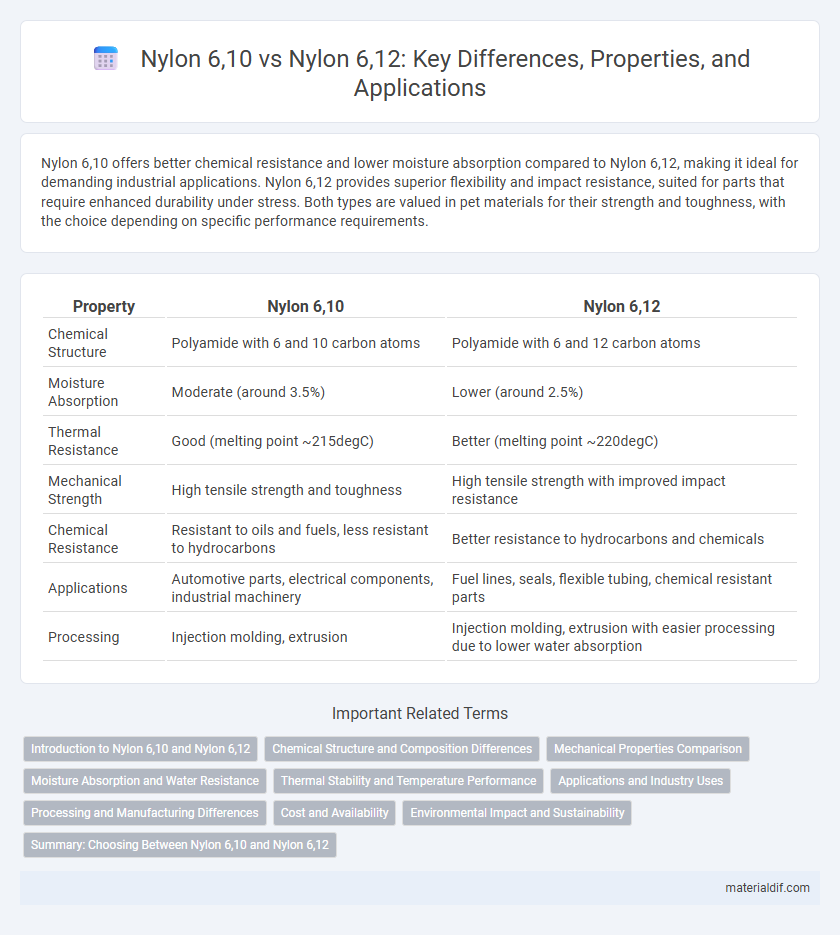

Nylon 6,10 offers better chemical resistance and lower moisture absorption compared to Nylon 6,12, making it ideal for demanding industrial applications. Nylon 6,12 provides superior flexibility and impact resistance, suited for parts that require enhanced durability under stress. Both types are valued in pet materials for their strength and toughness, with the choice depending on specific performance requirements.

Table of Comparison

| Property | Nylon 6,10 | Nylon 6,12 |

|---|---|---|

| Chemical Structure | Polyamide with 6 and 10 carbon atoms | Polyamide with 6 and 12 carbon atoms |

| Moisture Absorption | Moderate (around 3.5%) | Lower (around 2.5%) |

| Thermal Resistance | Good (melting point ~215degC) | Better (melting point ~220degC) |

| Mechanical Strength | High tensile strength and toughness | High tensile strength with improved impact resistance |

| Chemical Resistance | Resistant to oils and fuels, less resistant to hydrocarbons | Better resistance to hydrocarbons and chemicals |

| Applications | Automotive parts, electrical components, industrial machinery | Fuel lines, seals, flexible tubing, chemical resistant parts |

| Processing | Injection molding, extrusion | Injection molding, extrusion with easier processing due to lower water absorption |

Introduction to Nylon 6,10 and Nylon 6,12

Nylon 6,10 and Nylon 6,12 are polyamides known for their excellent chemical resistance, low moisture absorption, and enhanced dimensional stability compared to traditional Nylon 6 or Nylon 6,6. Nylon 6,10 is derived from hexamethylenediamine and sebacic acid, offering improved flexibility and better resistance to hydrocarbons and UV exposure. Nylon 6,12 is produced from hexamethylenediamine and dodecanedioic acid, delivering superior impact resistance and reduced water uptake, making it ideal for automotive and electrical applications requiring long-term durability.

Chemical Structure and Composition Differences

Nylon 6,10 consists of hexamethylenediamine and sebacic acid, resulting in a polymer with 6 carbon atoms from the diamine and 10 from the acid, which imparts higher moisture resistance and superior chemical stability. Nylon 6,12 is synthesized from hexamethylenediamine and dodecanedioic acid, featuring a 6-to-12 carbon atom ratio that provides enhanced flexibility, lower water absorption, and improved dimensional stability. The longer hydrocarbon chain in Nylon 6,12 contributes to its lower density and better resistance to hydrolysis compared to Nylon 6,10.

Mechanical Properties Comparison

Nylon 6,10 exhibits higher tensile strength and better chemical resistance compared to Nylon 6,12, making it suitable for applications requiring durability under mechanical stress. Nylon 6,12 offers superior flexibility and lower moisture absorption, enhancing impact resistance and dimensional stability in humid environments. Both polymers differ in elongation at break and hardness, with Nylon 6,10 generally being harder and less elongative than Nylon 6,12.

Moisture Absorption and Water Resistance

Nylon 6,10 exhibits significantly lower moisture absorption compared to Nylon 6,12, making it more suitable for applications requiring enhanced water resistance. The longer carbon chain in Nylon 6,10 reduces its hydrophilicity, resulting in improved dimensional stability under humid conditions. Nylon 6,12, while still moisture-resistant, absorbs more water due to its molecular structure, which can impact mechanical properties in wet environments.

Thermal Stability and Temperature Performance

Nylon 6,10 exhibits superior thermal stability compared to Nylon 6,12, with a higher melting point around 220degC versus 177degC for Nylon 6,12, making it more suitable for high-temperature applications. Nylon 6,10 maintains mechanical properties and dimensional stability at elevated temperatures, whereas Nylon 6,12 tends to soften and lose strength more quickly under thermal stress. This makes Nylon 6,10 preferable for components exposed to continuous heat, such as automotive under-the-hood parts and electrical connectors.

Applications and Industry Uses

Nylon 6,10 offers superior chemical resistance and lower moisture absorption than Nylon 6,12, making it ideal for automotive fuel lines and industrial tubing applications. Nylon 6,12 provides enhanced flexibility and dimensional stability, benefiting electrical cable sheathing and consumer goods manufacturing. Both variants are extensively used in industrial sectors, with Nylon 6,10 preferred for harsher chemical environments and Nylon 6,12 favored for lightweight, durable components.

Processing and Manufacturing Differences

Nylon 6,10 and Nylon 6,12 differ significantly in processing temperatures, with Nylon 6,10 melting around 215degC and Nylon 6,12 melting near 178degC, allowing Nylon 6,12 to be processed at lower temperatures, reducing energy consumption. The manufacturing of Nylon 6,10 typically involves adipic acid and hexamethylenediamine, while Nylon 6,12 uses laurolactam or dodecanedioic acid derivatives, resulting in distinct polymer chain structures that affect crystallinity and mechanical properties. Nylon 6,12's lower moisture absorption and enhanced chemical resistance influence molding cycles and post-processing conditions compared to Nylon 6,10, which requires more stringent drying and temperature control during extrusion and injection molding.

Cost and Availability

Nylon 6,10 typically offers lower production costs due to less expensive raw materials compared to Nylon 6,12, making it more cost-effective for large-scale manufacturing. Nylon 6,12 is generally less common and has limited availability, which can drive up its market price and extend lead times. Both types exhibit similar durability, but Nylon 6,10 is preferred in applications requiring budget-friendly sourcing and broader supply chain options.

Environmental Impact and Sustainability

Nylon 6,10 offers a lower environmental footprint compared to Nylon 6,12 due to its use of sebacic acid derived from castor oil, a renewable resource, reducing reliance on petrochemicals. Nylon 6,12 primarily depends on petroleum-based hexamethylenediamine and dodecanedioic acid, leading to higher greenhouse gas emissions and resource depletion. The biodegradability and carbon footprint of Nylon 6,10 are more favorable, making it a more sustainable choice for eco-conscious manufacturing.

Summary: Choosing Between Nylon 6,10 and Nylon 6,12

Nylon 6,10 offers superior chemical resistance and lower moisture absorption compared to Nylon 6,12, making it ideal for applications involving hydrocarbons and high humidity. Nylon 6,12 excels in flexibility and impact resistance with lower density, providing better dimensional stability and reduced water uptake. Selecting between Nylon 6,10 and Nylon 6,12 depends on balancing chemical tolerance against mechanical flexibility and weight requirements in specific industrial or automotive uses.

Nylon 6,10 vs Nylon 6,12 Infographic

materialdif.com

materialdif.com