Virgin nylon offers superior strength, durability, and consistent quality compared to recycled nylon, making it ideal for high-performance pet products. Recycled nylon presents an eco-friendly alternative by reducing waste and carbon footprint, though it may have slight variations in texture and resilience. Choosing between virgin and recycled nylon depends on balancing sustainability goals with the desired durability and longevity of pet accessories.

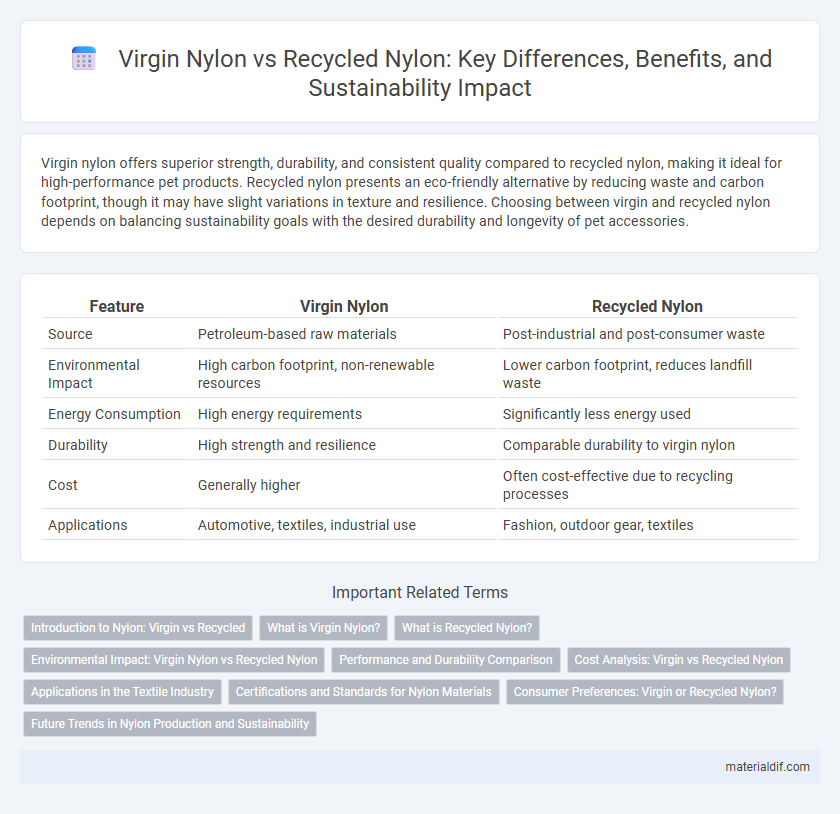

Table of Comparison

| Feature | Virgin Nylon | Recycled Nylon |

|---|---|---|

| Source | Petroleum-based raw materials | Post-industrial and post-consumer waste |

| Environmental Impact | High carbon footprint, non-renewable resources | Lower carbon footprint, reduces landfill waste |

| Energy Consumption | High energy requirements | Significantly less energy used |

| Durability | High strength and resilience | Comparable durability to virgin nylon |

| Cost | Generally higher | Often cost-effective due to recycling processes |

| Applications | Automotive, textiles, industrial use | Fashion, outdoor gear, textiles |

Introduction to Nylon: Virgin vs Recycled

Virgin nylon is produced from petrochemical raw materials, offering high strength, durability, and consistent quality for various applications such as textiles, automotive parts, and industrial components. Recycled nylon, derived from post-consumer or post-industrial waste, reduces environmental impact by lowering greenhouse gas emissions and decreasing reliance on non-renewable resources. Both virgin and recycled nylon maintain similar mechanical properties, but choosing recycled nylon supports sustainability goals and circular economy practices in manufacturing.

What is Virgin Nylon?

Virgin nylon is a type of synthetic polymer produced directly from petrochemical raw materials, ensuring consistent purity and strength. It offers superior durability, elasticity, and resilience compared to recycled nylon, making it ideal for high-performance applications. Manufacturers favor virgin nylon for its uniform molecular structure, which guarantees optimal quality and longevity in textiles, automotive parts, and industrial products.

What is Recycled Nylon?

Recycled nylon is produced from pre-consumer and post-consumer waste such as fishing nets, fabric scraps, and industrial plastic materials, significantly reducing environmental impact compared to virgin nylon made from petrochemicals. This sustainable alternative maintains the durability and performance characteristics of virgin nylon while lowering carbon emissions and reliance on non-renewable resources. Brands and manufacturers increasingly rely on recycled nylon to meet growing consumer demand for eco-friendly textiles and circular fashion solutions.

Environmental Impact: Virgin Nylon vs Recycled Nylon

Virgin nylon production relies heavily on fossil fuels, resulting in significant greenhouse gas emissions and high energy consumption. Recycled nylon reduces carbon footprint by reusing waste materials, conserving resources, and minimizing landfill waste, lowering environmental impact substantially. Utilizing recycled nylon supports circular economy principles and decreases reliance on finite raw materials.

Performance and Durability Comparison

Virgin nylon offers superior tensile strength and abrasion resistance, ensuring greater durability in high-stress applications. Recycled nylon matches closely in elasticity and resilience but may exhibit slightly reduced colorfastness and UV resistance due to prior processing. Both materials maintain excellent moisture-wicking properties, yet virgin nylon generally outperforms in long-term structural integrity.

Cost Analysis: Virgin vs Recycled Nylon

Virgin nylon typically incurs higher production costs due to raw material extraction and energy-intensive processes, whereas recycled nylon benefits from lower feedstock expenses by repurposing waste materials. Despite initial investment in sorting and recycling technology, recycled nylon often achieves cost savings through reduced energy consumption and diminished dependency on fossil fuels. Market fluctuations in petroleum prices heavily impact virgin nylon costs, making recycled nylon a more economically resilient choice for manufacturers focused on sustainability and cost efficiency.

Applications in the Textile Industry

Virgin nylon offers superior strength, elasticity, and durability, making it ideal for high-performance textiles such as sportswear, outdoor gear, and industrial fabrics. Recycled nylon, derived from pre- and post-consumer waste like fishing nets and fabric scraps, provides an eco-friendly alternative while maintaining comparable quality for applications in fashion, upholstery, and sustainable activewear. Textile manufacturers increasingly adopt recycled nylon to meet consumer demand for environmentally responsible products without compromising fabric performance.

Certifications and Standards for Nylon Materials

Virgin nylon is often certified under standards such as ISO 9001 for quality management and REACH compliance ensuring chemical safety, while recycled nylon frequently meets additional sustainability certifications like GRS (Global Recycled Standard) and OEKO-TEX for toxic-free production. Both materials must comply with stringent industry regulations regarding material traceability and environmental impact, but recycled nylon emphasizes circular economy principles and carbon footprint reduction. Certification processes for nylon materials involve rigorous testing of fiber integrity, purity, and environmental compliance to guarantee performance and safety in fashion and industrial applications.

Consumer Preferences: Virgin or Recycled Nylon?

Consumers show increasing preference for recycled nylon due to its environmental benefits, such as reduced carbon footprint and lower resource consumption compared to virgin nylon. Virgin nylon remains favored for its consistent quality, durability, and performance in high-end textiles and industrial applications. Market trends indicate a growing demand for sustainable materials, prompting brands to balance consumer expectations by offering products made from both virgin and recycled nylon.

Future Trends in Nylon Production and Sustainability

Virgin nylon production continues to rely heavily on petrochemical sources, contributing to significant carbon emissions and environmental degradation. Recycled nylon, derived from post-consumer waste like fishing nets and fabric scraps, is gaining traction as a sustainable alternative, reducing landfill waste and energy consumption by up to 80%. Future trends emphasize increased adoption of circular economy practices, improved recycling technologies, and development of bio-based nylon to minimize ecological impact and meet growing demand for eco-friendly materials.

Virgin nylon vs Recycled nylon Infographic

materialdif.com

materialdif.com