Impact-modified nylon offers enhanced toughness and resistance to cracking compared to unmodified nylon, making it ideal for applications requiring durability under stress. The modification process incorporates impact modifiers that improve the material's ability to absorb energy without breaking. Unmodified nylon, while strong and versatile, typically lacks this enhanced impact resistance, limiting its use in high-impact environments.

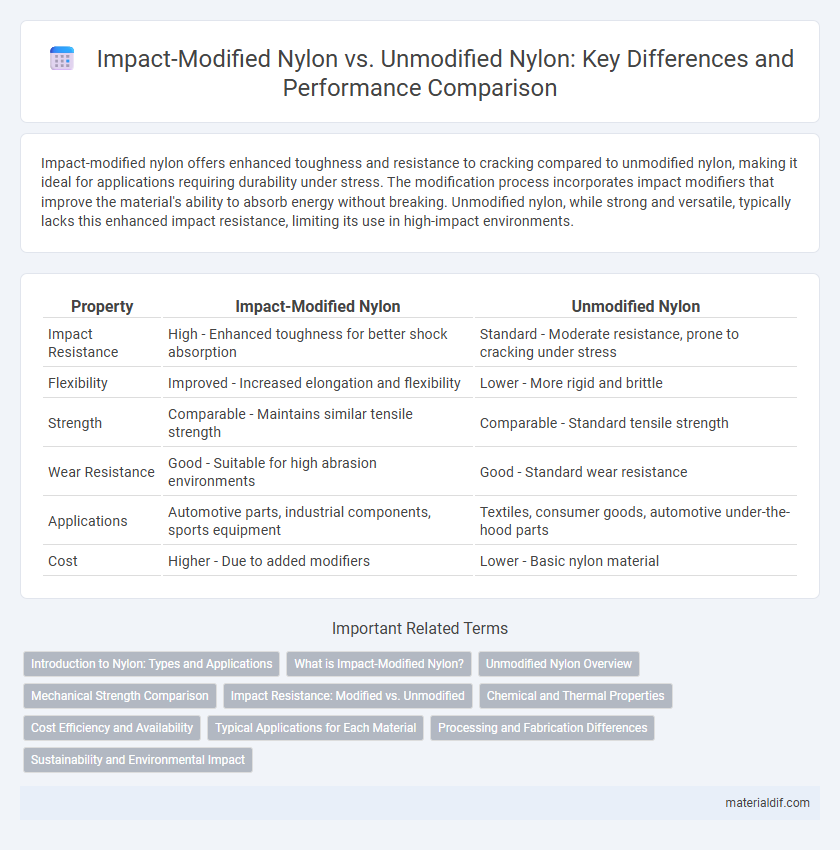

Table of Comparison

| Property | Impact-Modified Nylon | Unmodified Nylon |

|---|---|---|

| Impact Resistance | High - Enhanced toughness for better shock absorption | Standard - Moderate resistance, prone to cracking under stress |

| Flexibility | Improved - Increased elongation and flexibility | Lower - More rigid and brittle |

| Strength | Comparable - Maintains similar tensile strength | Comparable - Standard tensile strength |

| Wear Resistance | Good - Suitable for high abrasion environments | Good - Standard wear resistance |

| Applications | Automotive parts, industrial components, sports equipment | Textiles, consumer goods, automotive under-the-hood parts |

| Cost | Higher - Due to added modifiers | Lower - Basic nylon material |

Introduction to Nylon: Types and Applications

Impact-modified nylon features enhanced toughness and resistance to crack propagation compared to unmodified nylon, making it ideal for demanding engineering applications such as automotive components and industrial machinery parts. Unmodified nylon, known for its excellent mechanical strength, chemical resistance, and versatility, is widely used in textiles, consumer goods, and electrical insulators. Both types serve critical roles in manufacturing, with impact-modified nylon preferred where impact resistance is essential, while unmodified nylon is chosen for general-purpose uses.

What is Impact-Modified Nylon?

Impact-modified nylon is a type of nylon engineered with additives that enhance its toughness and resistance to impact, making it more durable in demanding applications compared to unmodified nylon. These modifications improve the polymer's ability to absorb and dissipate energy upon sudden forces, reducing the risk of cracking or breaking under stress. This enhanced toughness is critical in automotive parts, electrical components, and industrial equipment where mechanical resilience is essential.

Unmodified Nylon Overview

Unmodified nylon, a polyamide polymer, is known for its high tensile strength, excellent abrasion resistance, and good chemical stability, making it suitable for a variety of industrial applications. It offers superior stiffness and dimensional stability compared to impact-modified nylon but tends to exhibit lower impact resistance and reduced toughness under stress. Unmodified nylon's high melting point and moisture absorption properties influence its performance in molded parts and fibers, where rigidity and precision are critical.

Mechanical Strength Comparison

Impact-modified nylon exhibits enhanced mechanical strength, particularly in terms of impact resistance and toughness, compared to unmodified nylon. The addition of impact modifiers improves the material's ability to absorb and dissipate energy without cracking or breaking under sudden forces. Unmodified nylon, while possessing good tensile strength and stiffness, is more prone to brittle failure under high-impact conditions.

Impact Resistance: Modified vs. Unmodified

Impact-modified nylon exhibits significantly enhanced impact resistance compared to unmodified nylon due to the incorporation of elastomeric modifiers that improve toughness and reduce brittleness. Unmodified nylon tends to absorb less impact energy, making it more prone to cracking or failure under sudden mechanical stress. The improved molecular structure of impact-modified nylon allows it to dissipate kinetic energy more effectively, resulting in superior durability in high-impact applications.

Chemical and Thermal Properties

Impact-modified nylon contains elastomeric additives that enhance its chemical resistance and improve toughness under thermal stress, exhibiting higher impact strength and better dimensional stability at elevated temperatures compared to unmodified nylon. Unmodified nylon typically has a higher melting point around 260degC but is more prone to brittleness and chemical degradation when exposed to harsh environments or repeated thermal cycling. The incorporation of impact modifiers reduces susceptibility to cracking and chemical attack from oils, fuels, and solvents, making it suitable for demanding applications requiring enhanced durability and thermal resilience.

Cost Efficiency and Availability

Impact-modified nylon offers enhanced toughness and durability, making it suitable for demanding applications but typically comes at a higher cost compared to unmodified nylon. Unmodified nylon is more cost-efficient and widely available, providing a versatile option for general use where extreme impact resistance is not critical. Manufacturers often choose unmodified nylon for budget-sensitive projects due to its balance of performance and affordability.

Typical Applications for Each Material

Impact-modified nylon is commonly used in automotive components, electrical housings, and industrial machinery where enhanced toughness and resistance to impact are critical. Unmodified nylon typically suits applications such as textile fibers, consumer packaging, and electrical connectors where general mechanical strength and chemical resistance are required without extreme impact demands. Selecting between these materials depends on the necessity for improved durability versus standard performance in engineering and consumer products.

Processing and Fabrication Differences

Impact-modified nylon contains rubber or elastomer additives that improve toughness and resistance to cracking during high-stress applications, which affects processing parameters such as melt temperature and cooling rates compared to unmodified nylon. Unmodified nylon typically requires precise drying to prevent hydrolysis degradation during molding, while impact-modified variants often show greater moisture tolerance, allowing for slightly more flexible processing conditions. Fabrication techniques must account for the modified polymer's altered flow characteristics and mechanical behavior to optimize part quality and durability in impact-resistant applications.

Sustainability and Environmental Impact

Impact-modified nylon incorporates additives that enhance toughness and durability, which extends the lifespan of products and reduces material waste. Unmodified nylon tends to have lower resistance to impact, leading to more frequent replacements and greater resource consumption over time. Choosing impact-modified nylon supports sustainability by minimizing environmental impact through longer product use and decreased demand for raw nylon production.

Impact-Modified Nylon vs Unmodified Nylon Infographic

materialdif.com

materialdif.com