Thermoplastic nylon can be melted and reshaped multiple times, making it highly versatile for manufacturing processes like injection molding and extrusion. In contrast, thermoset nylon undergoes a curing process that creates a rigid, cross-linked structure, resulting in enhanced heat resistance and mechanical strength but preventing it from being remelted. This fundamental difference impacts their applications, with thermoplastic nylon favored for reusable, flexible designs and thermoset nylon preferred in high-temperature, durable component requirements.

Table of Comparison

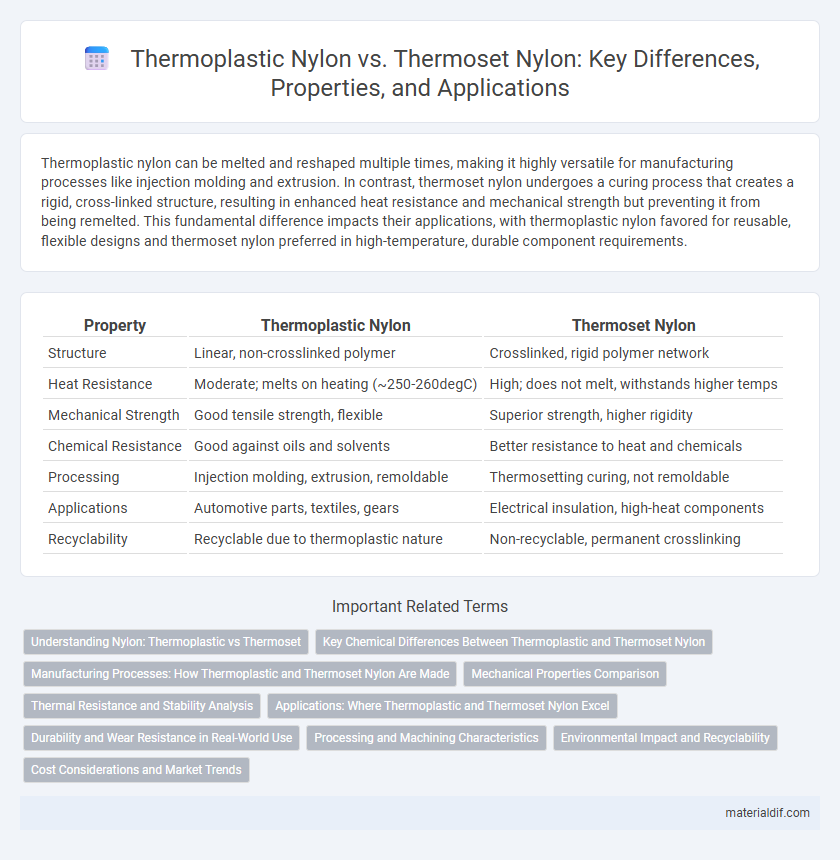

| Property | Thermoplastic Nylon | Thermoset Nylon |

|---|---|---|

| Structure | Linear, non-crosslinked polymer | Crosslinked, rigid polymer network |

| Heat Resistance | Moderate; melts on heating (~250-260degC) | High; does not melt, withstands higher temps |

| Mechanical Strength | Good tensile strength, flexible | Superior strength, higher rigidity |

| Chemical Resistance | Good against oils and solvents | Better resistance to heat and chemicals |

| Processing | Injection molding, extrusion, remoldable | Thermosetting curing, not remoldable |

| Applications | Automotive parts, textiles, gears | Electrical insulation, high-heat components |

| Recyclability | Recyclable due to thermoplastic nature | Non-recyclable, permanent crosslinking |

Understanding Nylon: Thermoplastic vs Thermoset

Thermoplastic nylon softens when heated, allowing it to be reshaped and recycled multiple times, making it suitable for applications requiring flexibility and reusability. Thermoset nylon undergoes a chemical curing process that creates irreversible cross-links, resulting in a rigid, heat-resistant material ideal for structural components and high-temperature environments. Understanding the differences in thermal behavior, mechanical properties, and processing methods between thermoplastic and thermoset nylon is essential for selecting the right material for engineering and manufacturing applications.

Key Chemical Differences Between Thermoplastic and Thermoset Nylon

Thermoplastic nylon consists of linear polymer chains that soften upon heating and harden when cooled, allowing for repeated reshaping due to their reversible intermolecular forces. In contrast, thermoset nylon features a three-dimensional cross-linked network formed during curing, which results in a permanent, infusible structure that cannot be remelted or reshaped after setting. The key chemical difference lies in the molecular architecture: thermoplastics have flexible, non-covalent bonds enabling thermal reprocessing, while thermosets possess strong covalent cross-links providing enhanced thermal stability and mechanical strength.

Manufacturing Processes: How Thermoplastic and Thermoset Nylon Are Made

Thermoplastic nylon is produced through a melting and molding process where pellets are heated until they liquefy and then injected or extruded into molds, allowing for easy reshaping and recycling. Thermoset nylon is formed by a chemical curing process involving cross-linking agents that create a rigid, heat-resistant polymer network, making the material set permanently and resistant to re-melting. These distinct manufacturing techniques result in thermoplastic nylon being more versatile for mass production, while thermoset nylon offers superior thermal stability and structural integrity for specialized applications.

Mechanical Properties Comparison

Thermoplastic nylon exhibits higher impact resistance and greater flexibility due to its ability to be reshaped under heat, making it ideal for applications requiring toughness and repeated molding. Thermoset nylon, characterized by cross-linked polymer chains, provides superior thermal stability and enhanced tensile strength, suitable for high-stress environments where dimensional stability is critical. Mechanical properties such as elongation at break, modulus of elasticity, and fatigue resistance vary significantly, with thermoplastic nylon excelling in ductility and thermoset nylon excelling in rigidity.

Thermal Resistance and Stability Analysis

Thermoplastic nylon exhibits excellent thermal resistance with the ability to soften and be reshaped at elevated temperatures, maintaining dimensional stability up to around 220degC. In contrast, thermoset nylon offers superior thermal stability due to its crosslinked molecular structure, which prevents melting and deformation, enduring temperatures above 250degC without compromising mechanical integrity. Thermal resistance analysis reveals thermoset nylon's enhanced performance in high-heat applications, making it ideal for components requiring persistent shape retention under thermal stress.

Applications: Where Thermoplastic and Thermoset Nylon Excel

Thermoplastic nylon excels in automotive components, electrical insulation, and consumer goods due to its excellent impact resistance, flexibility, and ease of molding. Thermoset nylon is preferred for high-performance applications requiring superior heat resistance, chemical stability, and dimensional stability, such as aerospace parts, industrial machinery, and electronic connectors. The choice between thermoplastic and thermoset nylon depends on specific performance requirements like thermal endurance, mechanical strength, and environmental exposure.

Durability and Wear Resistance in Real-World Use

Thermoplastic nylon offers superior durability and wear resistance in real-world applications due to its ability to flex under stress without cracking, making it ideal for components subject to repeated movement and impact. Thermoset nylon, however, provides exceptional thermal stability and chemical resistance, which enhances performance in high-temperature and corrosive environments but may be more brittle under mechanical stress. Choosing between them depends on balancing mechanical endurance with environmental resilience to maximize service life in specific industrial uses.

Processing and Machining Characteristics

Thermoplastic nylon offers excellent machinability due to its ability to melt and reform repeatedly, enabling versatile processing methods such as injection molding, extrusion, and thermoforming. In contrast, thermoset nylon undergoes a curing process that creates a rigid, cross-linked structure, resulting in limited re-melting capability and more challenging machining that often requires specialized cutting tools. Thermoplastic nylon's consistent flow properties ensure precise shaping and tighter tolerances, while thermoset nylon's enhanced thermal stability supports high-temperature applications despite its reduced machining flexibility.

Environmental Impact and Recyclability

Thermoplastic nylon offers superior recyclability due to its ability to be melted and reshaped multiple times, reducing environmental waste and conserving resources. Thermoset nylon, once cured, cannot be remelted or reformed, leading to greater disposal challenges and limited recycling options. The environmental impact of thermoset nylon is higher because its rigid crosslinked structure results in longer degradation times and increased landfill persistence.

Cost Considerations and Market Trends

Thermoplastic nylon generally offers lower production costs due to its recyclability and faster processing times, making it a preferred choice in automotive and consumer goods markets where cost efficiency is critical. Thermoset nylon, while more expensive because of its irreversible curing process and superior heat resistance, is favored in high-performance applications like aerospace and electrical insulation. Market trends indicate a growing demand for thermoplastic nylon driven by lightweight vehicle manufacturing and sustainability initiatives, whereas thermoset nylon maintains a niche presence in specialized industries requiring exceptional durability.

Thermoplastic Nylon vs Thermoset Nylon Infographic

materialdif.com

materialdif.com