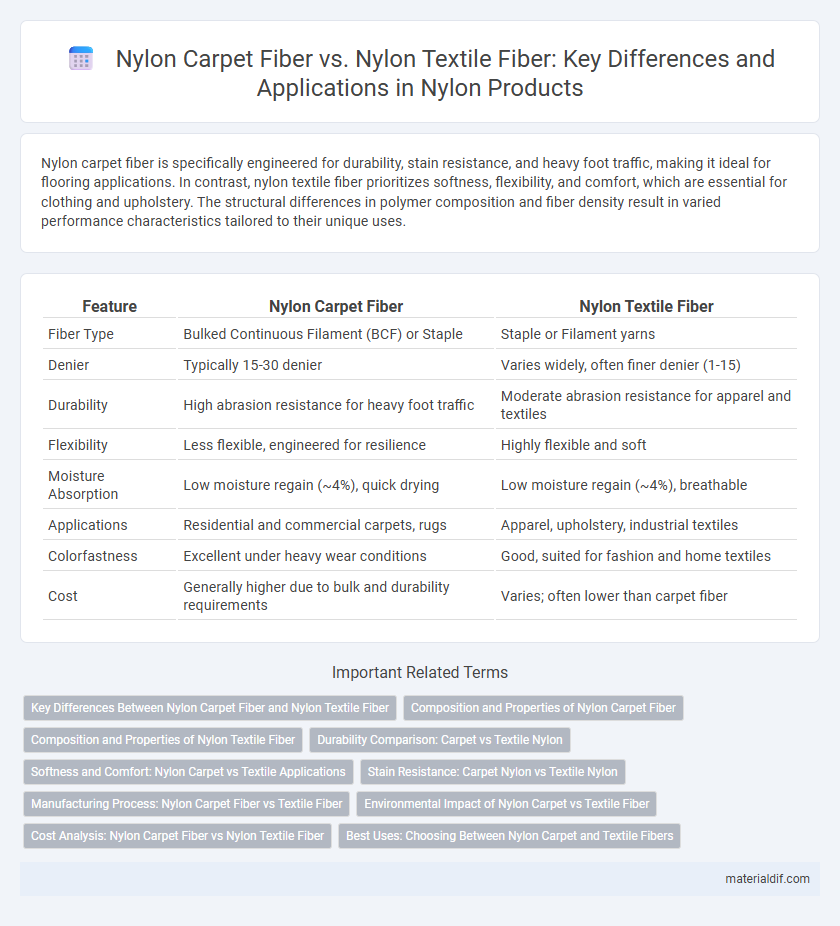

Nylon carpet fiber is specifically engineered for durability, stain resistance, and heavy foot traffic, making it ideal for flooring applications. In contrast, nylon textile fiber prioritizes softness, flexibility, and comfort, which are essential for clothing and upholstery. The structural differences in polymer composition and fiber density result in varied performance characteristics tailored to their unique uses.

Table of Comparison

| Feature | Nylon Carpet Fiber | Nylon Textile Fiber |

|---|---|---|

| Fiber Type | Bulked Continuous Filament (BCF) or Staple | Staple or Filament yarns |

| Denier | Typically 15-30 denier | Varies widely, often finer denier (1-15) |

| Durability | High abrasion resistance for heavy foot traffic | Moderate abrasion resistance for apparel and textiles |

| Flexibility | Less flexible, engineered for resilience | Highly flexible and soft |

| Moisture Absorption | Low moisture regain (~4%), quick drying | Low moisture regain (~4%), breathable |

| Applications | Residential and commercial carpets, rugs | Apparel, upholstery, industrial textiles |

| Colorfastness | Excellent under heavy wear conditions | Good, suited for fashion and home textiles |

| Cost | Generally higher due to bulk and durability requirements | Varies; often lower than carpet fiber |

Key Differences Between Nylon Carpet Fiber and Nylon Textile Fiber

Nylon carpet fiber is engineered for enhanced durability, abrasion resistance, and stain repellency to withstand heavy foot traffic, whereas nylon textile fiber prioritizes softness and flexibility for apparel and fabric applications. Carpet-grade nylon typically features a higher denier and increased resilience to crushing, while textile-grade nylon offers finer filaments tailored for comfort and aesthetic appeal. The manufacturing processes also differ, with carpet fibers often undergoing additional treatments like solution dyeing or UV stabilization to extend lifespan under harsh conditions.

Composition and Properties of Nylon Carpet Fiber

Nylon carpet fiber is primarily composed of polyamide polymers such as Nylon 6 and Nylon 6,6, which offer exceptional durability, abrasion resistance, and elasticity compared to typical nylon textile fibers used in apparel. These carpet fibers possess enhanced bulk and resilience, enabling them to withstand heavy foot traffic and maintain shape over time. The high tensile strength and excellent stain resistance of nylon carpet fibers make them a preferred choice for high-performance flooring applications.

Composition and Properties of Nylon Textile Fiber

Nylon textile fiber primarily consists of polyamide polymers such as nylon 6 and nylon 6,6, which provide superior strength, elasticity, and abrasion resistance compared to nylon carpet fiber formulations. The molecular structure of nylon textile fiber contributes to high durability, moisture-wicking ability, and resistance to chemicals and heat, making it ideal for apparel and technical textiles. In contrast, nylon carpet fibers often incorporate additional additives and treatments to enhance stain resistance and resilience suited for heavy foot traffic rather than consistent flexibility.

Durability Comparison: Carpet vs Textile Nylon

Nylon carpet fiber is engineered for superior abrasion resistance and resilience, making it ideal for high-traffic areas with frequent footfall. Textile-grade nylon fibers prioritize softness and flexibility, which can slightly reduce their long-term durability compared to carpet-grade fibers. Carpet nylon typically exhibits higher tensile strength and better recovery from compression, enhancing its lifespan in flooring applications versus textile nylon used in apparel.

Softness and Comfort: Nylon Carpet vs Textile Applications

Nylon carpet fiber is engineered for durability and resilience, featuring a slightly coarser texture that withstands heavy foot traffic while maintaining stain resistance. In contrast, nylon textile fiber prioritizes softness and comfort, offering a smoother, more flexible feel ideal for apparel and upholstery. The differentiated fiber treatments optimize each type for its specific use, resulting in carpet nylon that excels in toughness and textile nylon that enhances comfort.

Stain Resistance: Carpet Nylon vs Textile Nylon

Nylon carpet fiber is engineered with enhanced stain resistance, incorporating treatments like soil-release finishes and hydrophobic coatings that repel liquids and prevent dye absorption, making it ideal for high-traffic flooring applications. In contrast, nylon textile fiber used in apparel generally prioritizes softness and flexibility over stain resistance, often lacking specialized protective coatings found in carpet fibers. The molecular structure of carpet-grade nylon is typically denser and more resilient, contributing to superior durability and ease of cleaning compared to textile-grade nylon.

Manufacturing Process: Nylon Carpet Fiber vs Textile Fiber

Nylon carpet fiber manufacturing emphasizes durability through high-tenacity filament production and enhanced abrasion resistance via specialized heat treatment processes. In contrast, nylon textile fiber undergoes a more delicate spinning and drawing procedure designed to optimize softness, flexibility, and dye affinity for apparel applications. Both fibers utilize polymerization of hexamethylene diamine and adipic acid, but post-polymerization treatments differ to meet the specific mechanical and aesthetic demands of carpets versus textiles.

Environmental Impact of Nylon Carpet vs Textile Fiber

Nylon carpet fibers typically have a higher environmental impact than nylon textile fibers due to their denser production processes and shorter lifecycle, which result in increased energy consumption and waste generation. The manufacturing of nylon carpet fibers often involves more chemical treatments and additives that contribute to greater emissions and non-biodegradable waste. In contrast, nylon textile fibers are usually produced with optimized resource efficiency and longer use phases, reducing their overall carbon footprint and environmental burden.

Cost Analysis: Nylon Carpet Fiber vs Nylon Textile Fiber

Nylon carpet fiber generally costs less than nylon textile fiber due to differences in manufacturing processes and fiber specifications tailored for durability and resilience in flooring applications. Nylon textile fiber demands higher-grade materials and precision for softness, colorfastness, and appearance used in clothing, driving up production costs. Cost analysis indicates nylon carpet fiber offers a more budget-friendly option for large-scale applications, whereas nylon textile fiber justifies its premium price through enhanced comfort and aesthetic qualities.

Best Uses: Choosing Between Nylon Carpet and Textile Fibers

Nylon carpet fiber offers superior durability and stain resistance, making it ideal for high-traffic residential and commercial flooring applications. In contrast, nylon textile fiber provides enhanced softness and flexibility, suited for apparel, upholstery, and lightweight fabrics. Selecting between the two depends on the required balance of wear resistance versus comfort for specific end uses.

Nylon Carpet Fiber vs Nylon Textile Fiber Infographic

materialdif.com

materialdif.com