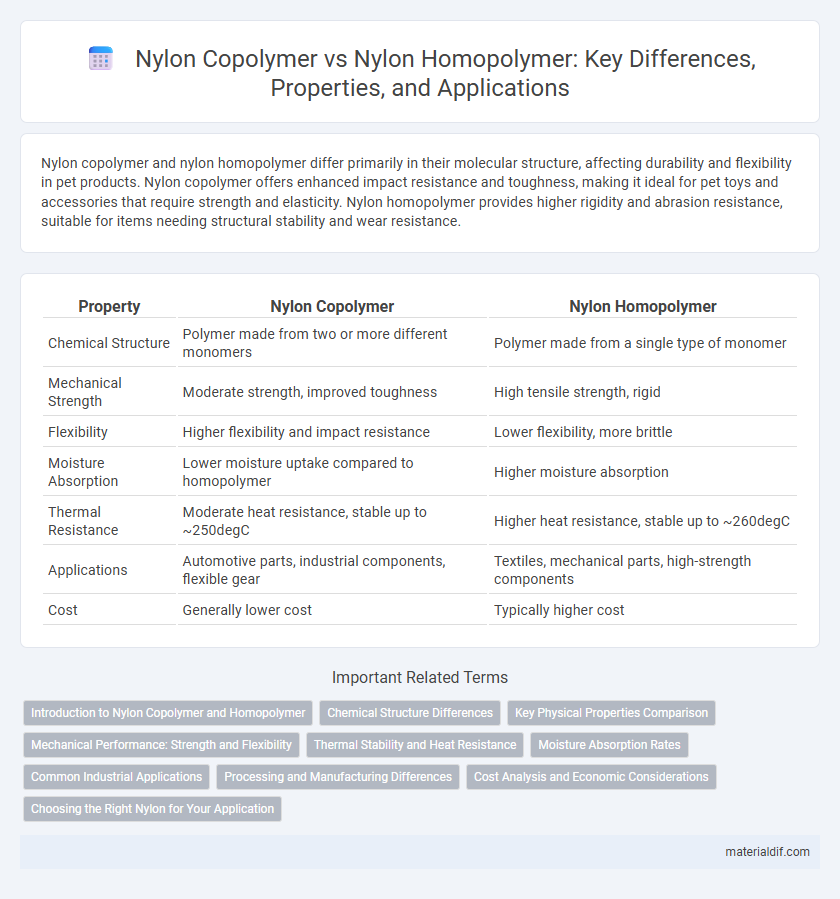

Nylon copolymer and nylon homopolymer differ primarily in their molecular structure, affecting durability and flexibility in pet products. Nylon copolymer offers enhanced impact resistance and toughness, making it ideal for pet toys and accessories that require strength and elasticity. Nylon homopolymer provides higher rigidity and abrasion resistance, suitable for items needing structural stability and wear resistance.

Table of Comparison

| Property | Nylon Copolymer | Nylon Homopolymer |

|---|---|---|

| Chemical Structure | Polymer made from two or more different monomers | Polymer made from a single type of monomer |

| Mechanical Strength | Moderate strength, improved toughness | High tensile strength, rigid |

| Flexibility | Higher flexibility and impact resistance | Lower flexibility, more brittle |

| Moisture Absorption | Lower moisture uptake compared to homopolymer | Higher moisture absorption |

| Thermal Resistance | Moderate heat resistance, stable up to ~250degC | Higher heat resistance, stable up to ~260degC |

| Applications | Automotive parts, industrial components, flexible gear | Textiles, mechanical parts, high-strength components |

| Cost | Generally lower cost | Typically higher cost |

Introduction to Nylon Copolymer and Homopolymer

Nylon copolymers consist of two or more different monomers, providing enhanced flexibility, improved impact resistance, and better thermal stability compared to nylon homopolymers, which are made from a single monomer type. Nylon homopolymers, such as Nylon 6, are known for their high strength, rigidity, and resistance to abrasion but can be more brittle. The chemical structure differences between copolymers and homopolymers influence their mechanical properties, making each suitable for specific industrial applications like automotive parts, textiles, and molded components.

Chemical Structure Differences

Nylon copolymers consist of two or more different monomer units chemically bonded, resulting in varied polymer chains with tailored properties. Nylon homopolymers, such as Nylon 6 or Nylon 6,6, are formed from a single type of monomer, producing a uniform molecular structure. The chemical structure differences directly influence crystallinity, melting point, and mechanical strength between copolymer and homopolymer nylons.

Key Physical Properties Comparison

Nylon copolymers exhibit enhanced impact resistance and flexibility compared to nylon homopolymers, which typically offer higher tensile strength and thermal stability. The copolymer's varied molecular structure reduces crystallinity, improving elongation at break and reducing brittleness. Homopolymers maintain superior chemical resistance and stiffness, making them ideal for applications requiring durability under mechanical stress.

Mechanical Performance: Strength and Flexibility

Nylon copolymers generally exhibit enhanced mechanical performance with improved flexibility and impact resistance compared to nylon homopolymers, making them ideal for applications requiring durability and toughness. Nylon homopolymers, such as Nylon 6, offer higher tensile strength and stiffness but tend to be more brittle under stress. The balance between strength and flexibility in copolymers is achieved by incorporating different monomers, optimizing their use in automotive parts, textiles, and industrial components.

Thermal Stability and Heat Resistance

Nylon copolymers exhibit enhanced thermal stability and heat resistance compared to nylon homopolymers due to their modified molecular structure, which disrupts regular polymer chains and reduces crystallinity. This structural variation allows copolymers to maintain mechanical properties at elevated temperatures, making them suitable for high-heat applications. In contrast, nylon homopolymers have higher crystallinity but lower thermal degradation thresholds, limiting their use in environments requiring prolonged heat exposure.

Moisture Absorption Rates

Nylon copolymers generally exhibit lower moisture absorption rates compared to nylon homopolymers due to their modified molecular structure, which reduces water affinity. Typical moisture absorption for nylon homopolymers like Nylon 6 or Nylon 6,6 ranges from 2.5% to 8%, whereas copolymers can absorb as little as 1% to 3%. This reduced moisture uptake enhances dimensional stability, mechanical properties, and electrical insulation performance in humid or wet environments.

Common Industrial Applications

Nylon copolymers, composed of two or more monomers, exhibit enhanced flexibility, chemical resistance, and impact strength, making them ideal for automotive parts, electrical connectors, and industrial machinery components. Nylon homopolymers, derived from a single monomer, offer higher tensile strength and thermal stability, which suit them for applications such as gears, bearings, and high-performance textiles. Both materials play crucial roles across industries, with copolymers favored in environments requiring durability under stress and homopolymers preferred for load-bearing and heat-resistant uses.

Processing and Manufacturing Differences

Nylon copolymers differ from nylon homopolymers primarily in their molecular structure, which affects processing conditions and manufacturing parameters. Copolymers generally exhibit better melt flow and enhanced thermal stability, allowing for lower molding temperatures and reduced cycle times compared to homopolymers. These differences enable manufacturers to select nylon grades tailored for specific injection molding or extrusion applications, optimizing productivity and product performance.

Cost Analysis and Economic Considerations

Nylon copolymer typically incurs higher production costs than nylon homopolymer due to the complexity of incorporating different monomers, which enhances specific properties such as impact resistance and flexibility. The increased material performance justifies the premium price in applications requiring durability, but for cost-sensitive markets, nylon homopolymer remains the preferred choice because of its lower raw material expenses and simpler manufacturing process. Economic considerations balance the initial material cost against long-term benefits like product lifespan and reduced maintenance, guiding manufacturers to select the appropriate nylon variant based on application needs and budget constraints.

Choosing the Right Nylon for Your Application

Nylon copolymer offers enhanced impact resistance and improved low-temperature performance compared to nylon homopolymer, making it ideal for applications requiring toughness and flexibility under varying environmental conditions. Nylon homopolymer provides higher tensile strength and better wear resistance, suitable for load-bearing or high-friction components. Selecting the right nylon depends on balancing mechanical strength with environmental durability to meet specific application demands.

Nylon Copolymer vs Nylon Homopolymer Infographic

materialdif.com

materialdif.com