Moisture-absorbed nylon exhibits increased flexibility and improved comfort in applications where breathability is essential, making it ideal for wearable products and outdoor gear. Dry nylon retains greater strength and abrasion resistance, which is beneficial in industrial uses and heavy-duty equipment. Understanding the distinct moisture interaction properties of these two types of nylon helps optimize material selection for performance and durability in specific environments.

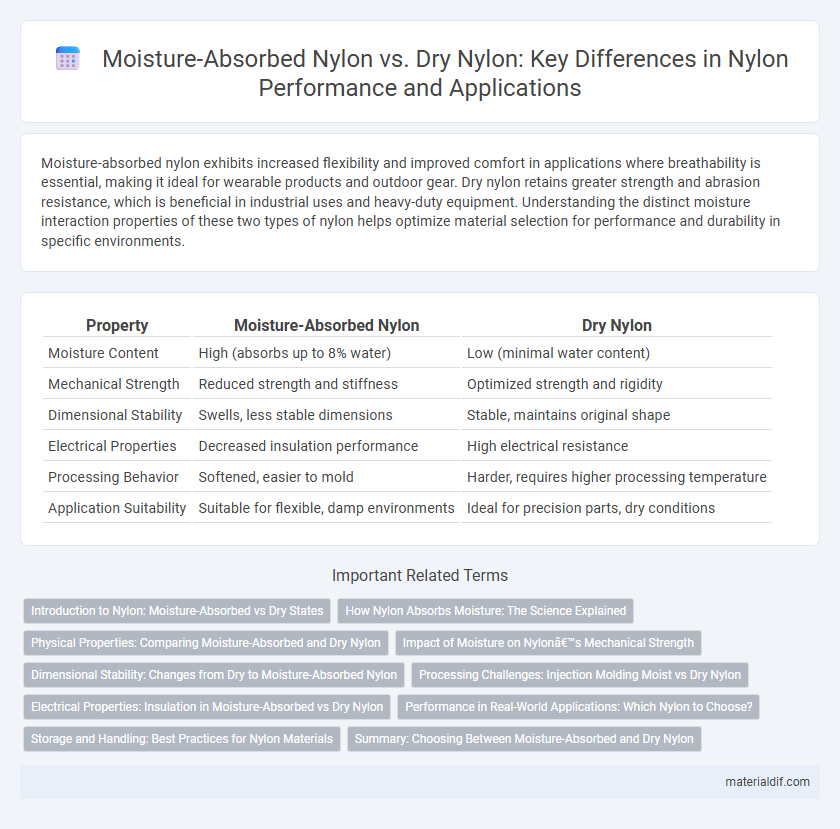

Table of Comparison

| Property | Moisture-Absorbed Nylon | Dry Nylon |

|---|---|---|

| Moisture Content | High (absorbs up to 8% water) | Low (minimal water content) |

| Mechanical Strength | Reduced strength and stiffness | Optimized strength and rigidity |

| Dimensional Stability | Swells, less stable dimensions | Stable, maintains original shape |

| Electrical Properties | Decreased insulation performance | High electrical resistance |

| Processing Behavior | Softened, easier to mold | Harder, requires higher processing temperature |

| Application Suitability | Suitable for flexible, damp environments | Ideal for precision parts, dry conditions |

Introduction to Nylon: Moisture-Absorbed vs Dry States

Nylon exhibits distinct physical and chemical properties when moisture-absorbed compared to its dry state, significantly affecting its mechanical strength, flexibility, and dimensional stability. Moisture absorption in nylon leads to increased plasticization, reducing brittleness and enhancing elongation, whereas dry nylon retains higher stiffness and tensile strength but is more susceptible to cracking under stress. Understanding the moisture-content-dependent behavior of nylon is crucial for applications in textiles, automotive parts, and engineering plastics where performance consistency is required.

How Nylon Absorbs Moisture: The Science Explained

Nylon absorbs moisture through its hydrophilic amide groups, which form hydrogen bonds with water molecules, increasing its weight and affecting its mechanical properties. Moisture diffusion into the nylon matrix leads to swelling, reduced tensile strength, and changes in flexibility, with absorption rates dependent on humidity and temperature conditions. This water-polymer interaction alters nylon's thermal stability and electrical insulation characteristics, critical factors in engineering and textile applications.

Physical Properties: Comparing Moisture-Absorbed and Dry Nylon

Moisture-absorbed nylon exhibits reduced tensile strength and increased elongation compared to dry nylon, which maintains higher rigidity and durability. The presence of absorbed moisture acts as a plasticizer, softening the polymer matrix and decreasing the glass transition temperature. Consequently, moisture-absorbed nylon demonstrates lower dimensional stability and altered mechanical performance in applications requiring precise physical properties.

Impact of Moisture on Nylon’s Mechanical Strength

Moisture-absorbed nylon shows a significant reduction in mechanical strength compared to dry nylon, with tensile strength typically dropping by 15-20% due to water molecules disrupting hydrogen bonding within the polymer matrix. The presence of water increases nylon's flexibility and reduces stiffness, resulting in lower Young's modulus and altered deformation behavior under load. These moisture-induced changes critically affect the performance of nylon in engineering applications, where consistent strength and durability are essential.

Dimensional Stability: Changes from Dry to Moisture-Absorbed Nylon

Moisture-absorbed nylon exhibits significant dimensional changes compared to dry nylon due to its high hygroscopic nature, with dimensional swelling rates typically ranging from 1% to 5%. This absorption leads to stress relaxation and distortion, impacting the material's dimensional stability in precision applications. Controlling environmental humidity and pre-conditioning nylon parts can mitigate these dimensional variations and ensure consistent performance.

Processing Challenges: Injection Molding Moist vs Dry Nylon

Moisture-absorbed nylon in injection molding can cause hydrolysis, leading to reduced molecular weight and compromised mechanical properties, resulting in surface imperfections and increased brittleness. Dry nylon, with moisture content below 0.2%, ensures stable viscosity and prevents voids or bubbles during molding, producing stronger, more consistent parts. Proper drying protocols, such as desiccant drying at 80-90degC for 4-6 hours, are essential to minimize moisture-induced defects and optimize injection molding performance.

Electrical Properties: Insulation in Moisture-Absorbed vs Dry Nylon

Moisture-absorbed nylon exhibits significantly lower electrical insulation properties compared to dry nylon due to increased conductivity from absorbed water molecules. Dry nylon maintains higher resistivity and dielectric strength, making it more effective as an insulator in electrical applications. The presence of moisture in nylon leads to reduced dielectric breakdown voltage and increased leakage currents, compromising insulation performance.

Performance in Real-World Applications: Which Nylon to Choose?

Moisture-absorbed nylon exhibits reduced tensile strength and increased elongation, impacting durability in high-stress environments. Dry nylon maintains optimal mechanical properties, making it ideal for precision components and load-bearing applications. Selecting between moisture-absorbed and dry nylon depends on the environmental conditions and performance requirements of the specific use case.

Storage and Handling: Best Practices for Nylon Materials

Moisture-absorbed nylon exhibits reduced mechanical strength and increased dimensional instability compared to dry nylon, making proper storage critical to maintain material integrity. Store nylon in moisture-controlled environments below 65% relative humidity and use airtight packaging with desiccants to prevent water absorption. Handle nylon materials with minimal exposure to humid conditions during processing to ensure optimal performance and longevity.

Summary: Choosing Between Moisture-Absorbed and Dry Nylon

Moisture-absorbed nylon exhibits increased flexibility and reduced brittleness compared to dry nylon but may experience compromised mechanical strength and dimensional stability. Dry nylon maintains optimal strength, stiffness, and consistent performance in applications sensitive to moisture-induced changes. Selecting between moisture-absorbed and dry nylon depends on the specific application requirements, environmental conditions, and desired material properties.

Moisture-Absorbed Nylon vs Dry Nylon Infographic

materialdif.com

materialdif.com