Nylon exhibits excellent impact resistance, allowing it to absorb sudden shocks and resist fracturing under dynamic loads. Its tensile strength, while significant, primarily determines how well it withstands continuous pulling forces without breaking. Comparing the two, impact resistance is critical for applications requiring durability against abrupt forces, whereas tensile strength is vital for maintaining structural integrity under sustained tension.

Table of Comparison

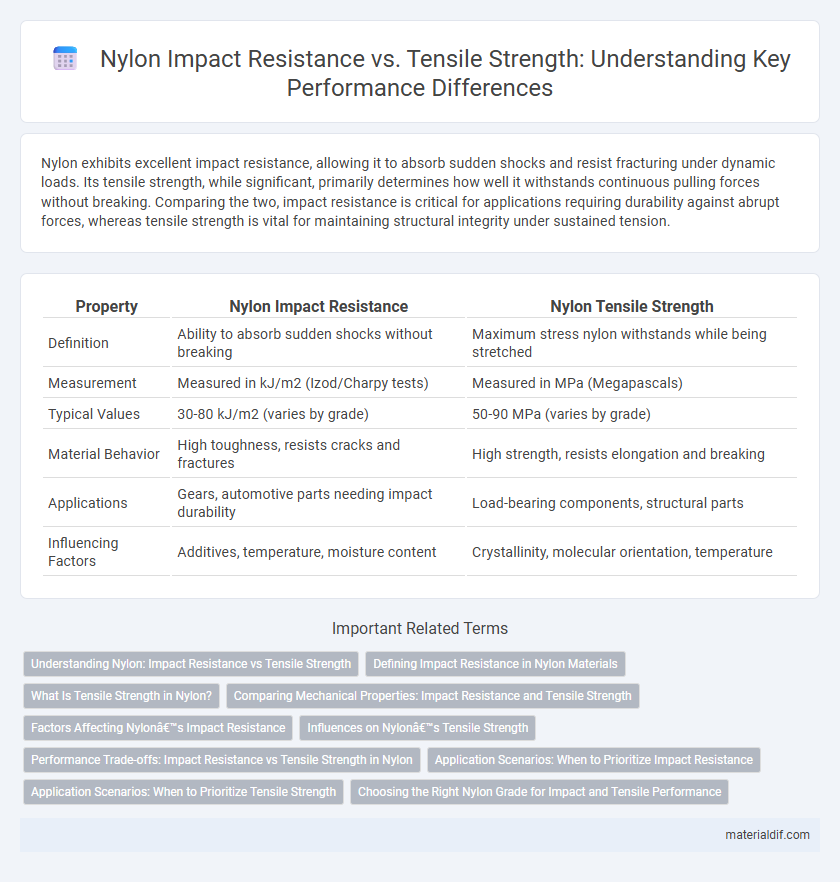

| Property | Nylon Impact Resistance | Nylon Tensile Strength |

|---|---|---|

| Definition | Ability to absorb sudden shocks without breaking | Maximum stress nylon withstands while being stretched |

| Measurement | Measured in kJ/m2 (Izod/Charpy tests) | Measured in MPa (Megapascals) |

| Typical Values | 30-80 kJ/m2 (varies by grade) | 50-90 MPa (varies by grade) |

| Material Behavior | High toughness, resists cracks and fractures | High strength, resists elongation and breaking |

| Applications | Gears, automotive parts needing impact durability | Load-bearing components, structural parts |

| Influencing Factors | Additives, temperature, moisture content | Crystallinity, molecular orientation, temperature |

Understanding Nylon: Impact Resistance vs Tensile Strength

Nylon demonstrates high impact resistance, allowing it to absorb shock and resist sudden forces without cracking or breaking. Its tensile strength varies by type, with Nylon 6 and Nylon 6,6 offering tensile strengths typically between 70 and 90 MPa, making it suitable for applications requiring durability and load-bearing capacity. Understanding the balance between Nylon's impact resistance and tensile strength is crucial for optimizing material selection in engineering and manufacturing.

Defining Impact Resistance in Nylon Materials

Impact resistance in nylon materials refers to their ability to absorb and dissipate energy during sudden forces or shocks without fracturing, which is critical for applications involving dynamic loads. While tensile strength measures nylon's capacity to withstand pulling forces without breaking, impact resistance emphasizes toughness and durability under rapid impact conditions. The molecular structure and degree of crystallinity in nylon significantly influence its impact resistance, with amorphous regions contributing to higher toughness compared to purely tensile strength properties.

What Is Tensile Strength in Nylon?

Tensile strength in nylon measures the maximum stress the material can withstand while being stretched without breaking, directly impacting its durability in applications requiring resistance to pulling forces. Nylon typically exhibits high tensile strength due to its strong molecular chains, enabling it to endure heavy loads and mechanical stress. This property is crucial for engineering uses where both flexibility and robust structural integrity are essential.

Comparing Mechanical Properties: Impact Resistance and Tensile Strength

Nylon exhibits high tensile strength, typically ranging from 50 to 80 MPa, allowing it to withstand significant pulling forces without breaking. Its impact resistance, often measured by Izod impact strength, is notable but generally lower compared to its tensile strength, with values around 50 to 100 J/m. This distinction highlights nylon's superior ability to resist mechanical stress (tensile loads) over sudden shock or impact forces, influencing material selection for applications requiring either durability under tension or toughness against impact.

Factors Affecting Nylon’s Impact Resistance

Nylon's impact resistance is influenced by factors such as molecular weight, crystallinity, and temperature, which determine its ability to absorb and dissipate energy without fracturing. Although tensile strength measures the material's resistance to being pulled apart, impact resistance depends more on the polymer's toughness and ability to deform under sudden stress. Additives, moisture content, and processing techniques significantly affect Nylon's balance between impact resistance and tensile strength, with higher moisture generally reducing impact resistance due to plasticization effects.

Influences on Nylon’s Tensile Strength

Nylon's tensile strength is primarily influenced by its molecular structure, degree of crystallinity, and moisture content, which affect fiber alignment and load distribution. Impact resistance, while related to tensile strength, depends more on Nylon's ability to absorb energy and deform without breaking, often enhanced by additives or specific processing techniques. Understanding these factors allows optimization of Nylon formulations for applications requiring both high tensile strength and impact resistance.

Performance Trade-offs: Impact Resistance vs Tensile Strength in Nylon

Nylon exhibits a notable performance trade-off between impact resistance and tensile strength, where enhancing one typically compromises the other. High impact resistance in Nylon is achieved through increased toughness and flexibility, allowing it to absorb shocks without fracturing, whereas elevated tensile strength results from molecular alignment and crystallinity, providing greater load-bearing capacity but reduced ductility. Optimizing Nylon for specific applications requires balancing these properties to ensure sufficient durability under repeated stress without sacrificing strength.

Application Scenarios: When to Prioritize Impact Resistance

Nylon's impact resistance is crucial in applications requiring energy absorption and durability under sudden forces, such as automotive components, protective gear, and industrial machinery parts. When parts are subject to shocks, drops, or frequent collisions, prioritizing impact resistance over tensile strength ensures longevity and safety. Conversely, tensile strength is more important in load-bearing applications like structural supports and mechanical fasteners where sustained pulling forces dominate.

Application Scenarios: When to Prioritize Tensile Strength

Nylon's tensile strength is crucial in applications requiring resistance to heavy loads and prolonged stress, such as in industrial gears, ropes, and load-bearing components, where durability under tension is essential. Impact resistance suits scenarios involving sudden forces or shocks, like protective housings or casings, but tensile strength takes priority in structural parts that must withstand continuous pulling or stretching. Choosing nylon grades with higher tensile strength ensures reliability in mechanical and automotive components subjected to constant stress and strain.

Choosing the Right Nylon Grade for Impact and Tensile Performance

Nylon grades vary significantly in impact resistance and tensile strength, with Nylon 6 offering higher tensile strength ideal for load-bearing applications, while Nylon 6/6 demonstrates superior impact resistance suitable for shock-absorbing components. Selecting the right nylon grade requires balancing these properties based on the specific demands of the application, such as wear resistance, flexibility, and environmental factors. High-performance Nylon composites or reinforced variants can optimize both impact resistance and tensile strength for advanced engineering needs.

Nylon impact resistance vs Nylon tensile strength Infographic

materialdif.com

materialdif.com