Nylon grades with high amide content exhibit superior mechanical strength, abrasion resistance, and thermal stability compared to those with low amide content. The increased amide concentration enhances the polymer's hydrogen bonding, resulting in improved durability and chemical resistance, making it ideal for demanding applications such as industrial textiles and automotive components. Conversely, low amide content nylons offer greater flexibility and lower moisture absorption, suitable for lightweight and flexible products.

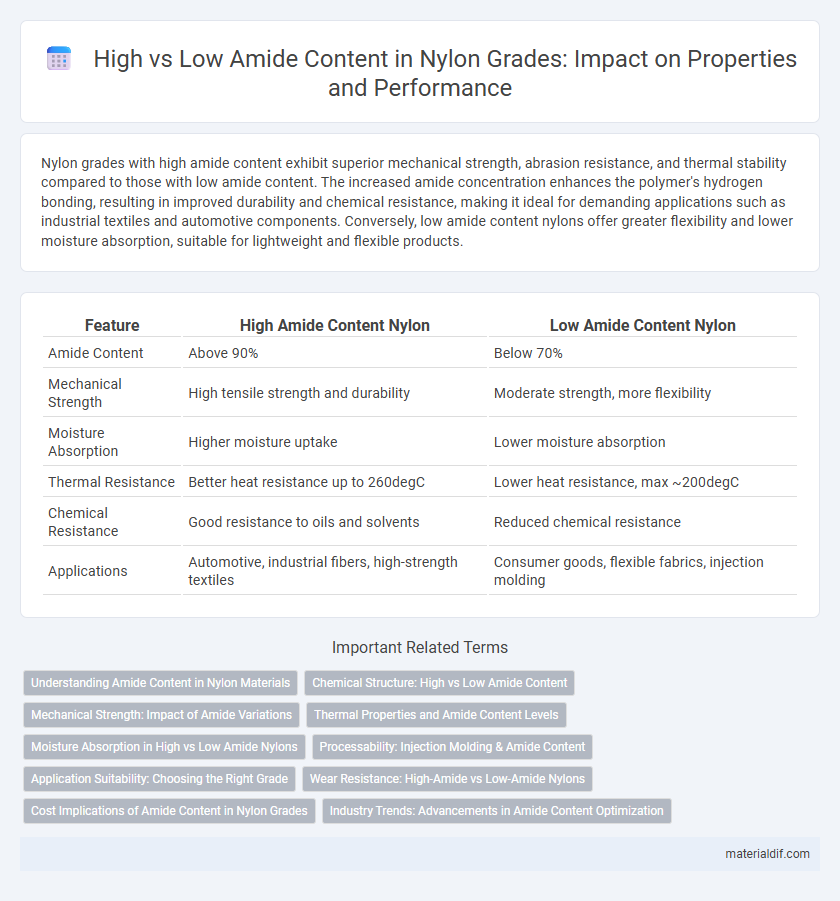

Table of Comparison

| Feature | High Amide Content Nylon | Low Amide Content Nylon |

|---|---|---|

| Amide Content | Above 90% | Below 70% |

| Mechanical Strength | High tensile strength and durability | Moderate strength, more flexibility |

| Moisture Absorption | Higher moisture uptake | Lower moisture absorption |

| Thermal Resistance | Better heat resistance up to 260degC | Lower heat resistance, max ~200degC |

| Chemical Resistance | Good resistance to oils and solvents | Reduced chemical resistance |

| Applications | Automotive, industrial fibers, high-strength textiles | Consumer goods, flexible fabrics, injection molding |

Understanding Amide Content in Nylon Materials

High amide content in nylon grades enhances hydrogen bonding between polymer chains, resulting in increased tensile strength, thermal resistance, and chemical stability. Low amide content nylon typically offers greater flexibility, improved moisture absorption, and easier dyeability but may sacrifice some mechanical durability. Understanding the balance of amide content allows manufacturers to tailor nylon materials for specific applications, optimizing performance characteristics such as abrasion resistance and environmental resilience.

Chemical Structure: High vs Low Amide Content

Nylon grades with high amide content exhibit a greater density of amide (-CONH-) linkages within their polymer chains, resulting in stronger intermolecular hydrogen bonding and enhanced crystallinity. In contrast, low amide content nylons have fewer amide groups, leading to reduced hydrogen bonding and increased chain flexibility, which affects their mechanical and thermal properties. The variation in amide content directly influences nylon's chemical resilience, moisture absorption, and tensile strength due to differences in molecular structure and interchain interactions.

Mechanical Strength: Impact of Amide Variations

Nylon grades with high amide content exhibit increased hydrogen bonding, resulting in enhanced mechanical strength and superior impact resistance. In contrast, low amide content in nylon reduces intermolecular forces, leading to decreased tensile strength and lower durability under mechanical stress. The variation in amide levels directly influences the polymer's crystallinity, affecting its toughness and performance in demanding applications.

Thermal Properties and Amide Content Levels

Nylon grades with high amide content exhibit superior thermal stability and higher melting points, typically ranging from 215degC to 265degC, due to increased hydrogen bonding in the polymer chains. Low amide content nylons generally have reduced crystallinity and melt at lower temperatures around 180degC to 210degC, resulting in decreased thermal resistance and mechanical strength at elevated temperatures. The variation in amide content significantly influences nylon's heat deflection temperature, with high amide variants preferred for applications requiring enhanced thermal performance.

Moisture Absorption in High vs Low Amide Nylons

Nylons with high amide content exhibit significantly greater moisture absorption due to the increased number of polar amide groups that attract water molecules. This higher moisture uptake affects dimensional stability and mechanical properties, making high-amide nylons more prone to swelling and reduced strength in humid environments. Low amide content nylons absorb less moisture, enhancing their resistance to environmental humidity and maintaining performance consistency.

Processability: Injection Molding & Amide Content

Nylon grades with high amide content typically exhibit improved crystallinity, resulting in enhanced mechanical strength and chemical resistance, which can challenge injection molding due to increased melting temperatures and slower flow rates. Conversely, nylons with low amide content have lower melting points and reduced crystallinity, offering better processability during injection molding with faster cycle times and easier flow through molds. Optimizing amide content balances mechanical properties and processability, allowing manufacturers to select nylon grades tailored for specific injection molding applications.

Application Suitability: Choosing the Right Grade

Nylon grades with high amide content offer superior strength, chemical resistance, and thermal stability, making them ideal for demanding applications such as automotive parts, industrial machinery, and high-performance textiles. Low amide content nylons provide greater flexibility and moisture absorption, suitable for applications like packaging films, wearable fabrics, and consumer goods requiring softer material properties. Selecting the appropriate nylon grade depends on balancing mechanical performance and environmental exposure to ensure optimal durability and functionality in the intended use.

Wear Resistance: High-Amide vs Low-Amide Nylons

High-amide content nylons exhibit superior wear resistance due to their increased intermolecular hydrogen bonding, which enhances mechanical strength and abrasion durability. Low-amide nylons, with reduced amide groups, typically show lower wear performance but offer better flexibility and impact resistance. The balance between amide content and polymer structure determines optimal applications, where high-amide nylons are preferred for demanding, high-friction environments.

Cost Implications of Amide Content in Nylon Grades

Nylon grades with high amide content generally exhibit superior mechanical strength and chemical resistance, leading to higher production costs due to increased raw material requirements and complex manufacturing processes. Conversely, low amide content nylons offer more cost-effective solutions with reduced durability and lower melting points, making them suitable for applications prioritizing budget over performance. The balance between amide content and cost is critical for manufacturers aiming to optimize product specifications while controlling material expenses in the nylon supply chain.

Industry Trends: Advancements in Amide Content Optimization

High amide content in nylon grades enhances mechanical strength and thermal resistance, making them ideal for automotive and aerospace applications demanding durability and heat stability. Lower amide content nylon offers increased flexibility and improved moisture resistance, preferred in textile and consumer goods industries. Industry trends focus on advanced polymerization techniques and molecular structure modifications to optimize amide content, balancing performance attributes for specialized uses and sustainable manufacturing.

Amide Content High vs Amide Content Low (in Nylon Grades) Infographic

materialdif.com

materialdif.com