Nylon monofilament consists of a single continuous strand, offering a smooth surface, high tensile strength, and excellent abrasion resistance, making it ideal for durable pet collars and leashes. Nylon multifilament is composed of multiple intertwined fibers, providing greater flexibility, softness, and comfort for pets, often used in harnesses and softer accessories. Choosing between monofilament and multifilament nylon depends on the desired balance between strength and comfort in pet products.

Table of Comparison

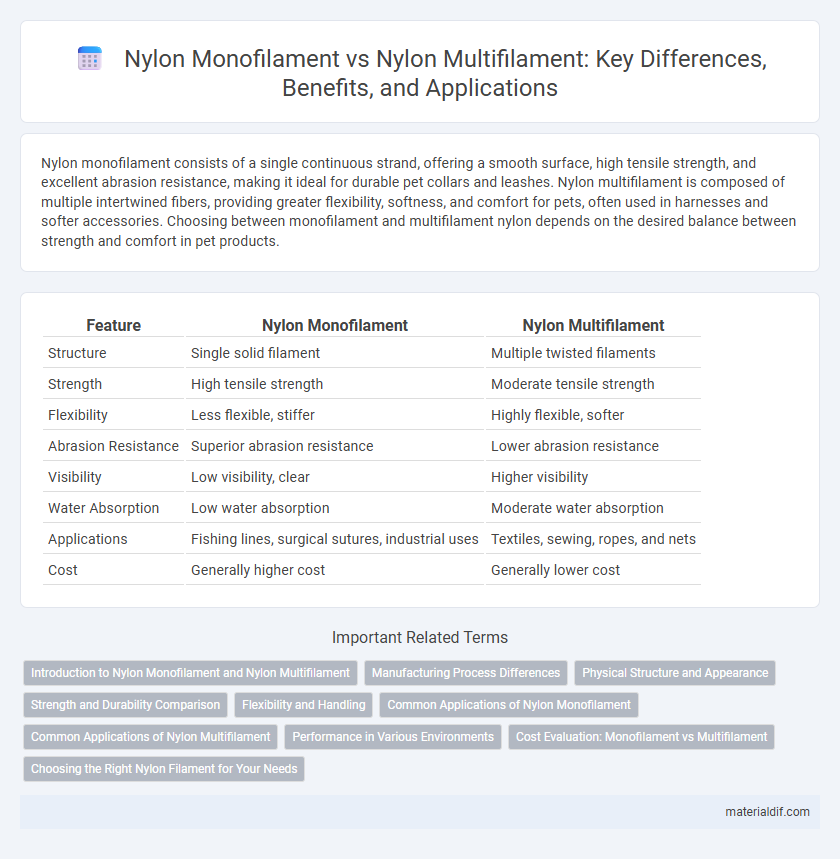

| Feature | Nylon Monofilament | Nylon Multifilament |

|---|---|---|

| Structure | Single solid filament | Multiple twisted filaments |

| Strength | High tensile strength | Moderate tensile strength |

| Flexibility | Less flexible, stiffer | Highly flexible, softer |

| Abrasion Resistance | Superior abrasion resistance | Lower abrasion resistance |

| Visibility | Low visibility, clear | Higher visibility |

| Water Absorption | Low water absorption | Moderate water absorption |

| Applications | Fishing lines, surgical sutures, industrial uses | Textiles, sewing, ropes, and nets |

| Cost | Generally higher cost | Generally lower cost |

Introduction to Nylon Monofilament and Nylon Multifilament

Nylon monofilament consists of a single continuous filament, offering high tensile strength, abrasion resistance, and smooth texture ideal for precision applications such as fishing lines and surgical sutures. Nylon multifilament is composed of multiple fine fibers twisted together, providing enhanced flexibility, softness, and knot strength suited for textiles, ropes, and industrial fabrics. Both types exploit nylon's durability and elasticity, yet their structural differences tailor them to distinct performance needs.

Manufacturing Process Differences

Nylon monofilament is produced by extruding a single continuous filament through spinnerets, resulting in a smooth, strong, and uniform fiber ideal for applications requiring high tensile strength. In contrast, nylon multifilament manufacturing involves spinning multiple fine filaments simultaneously before twisting or weaving them into a yarn, enhancing flexibility and bulk for uses like fishing lines or textiles. The key difference lies in monofilament's single-filament extrusion versus multifilament's multi-filament spinning and texturizing processes, affecting the final fiber's mechanical properties and surface texture.

Physical Structure and Appearance

Nylon monofilament consists of a single, continuous filament that provides a smooth, uniform appearance and high tensile strength with minimal flexibility. Nylon multifilament is made up of many fine filaments twisted together, resulting in a softer texture and greater flexibility but less resistance to abrasion. The physical structure differences influence their applications, with monofilament favored for strength and durability, while multifilament is preferred for comfort and pliability in fabrics.

Strength and Durability Comparison

Nylon monofilament offers superior tensile strength and abrasion resistance due to its single, continuous fiber construction, making it highly durable for heavy-duty applications. Nylon multifilament consists of numerous fine fibers twisted together, providing greater flexibility and softness but generally lower overall strength compared to monofilament. In terms of durability, monofilament resists wear and environmental stress better, while multifilament is prone to fraying and less resistant to UV degradation.

Flexibility and Handling

Nylon monofilament offers higher stiffness and less flexibility, making it ideal for applications requiring precise control and minimal stretch. In contrast, nylon multifilament provides superior flexibility and softness, enhancing handling and comfort in tasks needing greater maneuverability. The braided structure of multifilament nylon contributes to its enhanced elasticity and abrasion resistance compared to the smooth, single-strand monofilament.

Common Applications of Nylon Monofilament

Nylon monofilament is widely used in fishing lines, industrial sewing threads, and medical sutures due to its high tensile strength, smooth surface, and durability. Its single-strand construction provides excellent abrasion resistance and minimal water absorption, making it ideal for applications requiring precision and reliability. Common applications also include bristle brushes and cable ties, benefiting from nylon monofilament's stiffness and resilience.

Common Applications of Nylon Multifilament

Nylon multifilament is widely used in textile industries for manufacturing durable fabrics, ropes, and fishing lines due to its enhanced flexibility and strength compared to monofilament. Its multiple intertwined fibers offer superior elasticity and abrasion resistance, making it ideal for sportswear, upholstery, and industrial sewing threads. Industries also favor nylon multifilament for creating complex braided structures in automotive and marine applications.

Performance in Various Environments

Nylon monofilament offers superior abrasion resistance and strength, making it ideal for environments with high friction and wear. Nylon multifilament provides enhanced flexibility and knot strength, performing better in dynamic conditions that require elasticity and shock absorption. Both types exhibit excellent resistance to chemicals and UV exposure, but selecting between monofilament and multifilament depends on the specific performance needs of the application.

Cost Evaluation: Monofilament vs Multifilament

Nylon monofilament generally incurs lower production costs due to its simpler manufacturing process, making it a cost-effective option for applications requiring strength and durability with minimal flexibility. In contrast, nylon multifilament involves higher material and processing expenses as it consists of multiple fine filaments twisted together, offering enhanced flexibility and abrasion resistance but at an increased price. Evaluating cost versus performance is critical for manufacturers seeking the optimal balance between budget constraints and application-specific requirements.

Choosing the Right Nylon Filament for Your Needs

Nylon monofilament offers high tensile strength and excellent abrasion resistance, making it ideal for applications requiring durability and smooth performance, such as fishing lines and industrial threads. Nylon multifilament, composed of multiple fine fibers twisted together, provides superior flexibility and softness, perfect for textiles and brushes where comfort and pliability are essential. Choosing the right nylon filament depends on the specific requirements for strength, flexibility, and surface finish in your project.

Nylon monofilament vs Nylon multifilament Infographic

materialdif.com

materialdif.com