Nylon sheets provide a versatile flat surface ideal for cutting, shaping, and fabrication in applications requiring durability and wear resistance. Nylon rods offer excellent strength and rigidity, making them suitable for machining into custom parts such as gears, shafts, and bearings. Choosing between nylon sheet and nylon rod depends on the specific project requirements for thickness, flexibility, and load-bearing capacity.

Table of Comparison

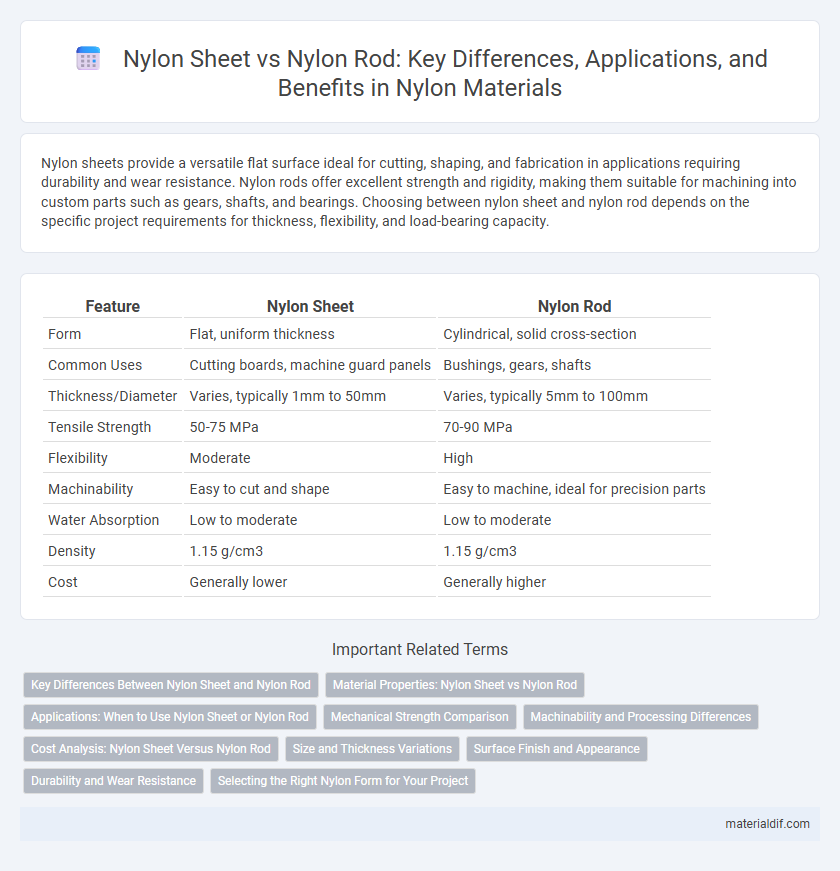

| Feature | Nylon Sheet | Nylon Rod |

|---|---|---|

| Form | Flat, uniform thickness | Cylindrical, solid cross-section |

| Common Uses | Cutting boards, machine guard panels | Bushings, gears, shafts |

| Thickness/Diameter | Varies, typically 1mm to 50mm | Varies, typically 5mm to 100mm |

| Tensile Strength | 50-75 MPa | 70-90 MPa |

| Flexibility | Moderate | High |

| Machinability | Easy to cut and shape | Easy to machine, ideal for precision parts |

| Water Absorption | Low to moderate | Low to moderate |

| Density | 1.15 g/cm3 | 1.15 g/cm3 |

| Cost | Generally lower | Generally higher |

Key Differences Between Nylon Sheet and Nylon Rod

Nylon sheets offer flat, uniform surfaces ideal for applications requiring consistent thickness and easy machining, while nylon rods provide cylindrical shapes suited for turning and drilling tasks. The mechanical properties of nylon sheets typically include higher tensile strength and rigidity compared to rods, making sheets preferable for structural components. Nylon rods are favored for rotational parts and shafts due to their consistent diameter and ease of shaping on lathes.

Material Properties: Nylon Sheet vs Nylon Rod

Nylon sheets offer uniform thickness and are ideal for applications requiring flat, stable surfaces with excellent wear resistance and chemical stability. Nylon rods provide high strength and toughness with consistent diameter, suitable for machining into durable mechanical parts and components. Both materials exhibit high abrasion resistance, low friction, and good impact resistance, but sheets excel in structural applications while rods are preferred for precision engineering.

Applications: When to Use Nylon Sheet or Nylon Rod

Nylon sheets are ideal for applications requiring large, flat surfaces like wear pads, machine guards, or spacers because they offer easy cutting and drilling. Nylon rods are better suited for precision machining into shafts, pins, or bushings where strength and durability in cylindrical forms are essential. Choose nylon sheet for structural support and nylon rod for rotational or load-bearing parts in mechanical assemblies.

Mechanical Strength Comparison

Nylon rods exhibit superior mechanical strength compared to nylon sheets due to their uniform density and absence of stress concentrations, making them ideal for high-load applications such as bearings and bushings. The axial alignment in nylon rods enhances tensile strength and impact resistance, whereas nylon sheets provide more flexibility but lower load-bearing capacity. Choosing between nylon sheet and rod depends on the specific strength requirements and mechanical demands of the project.

Machinability and Processing Differences

Nylon sheets offer superior surface flatness and uniform thickness, making them ideal for precise machining and intricate detailing, while nylon rods provide better strength and stability for turning and cylindrical shaping. Sheets typically require less post-processing due to their smooth finish, whereas rods may need additional surfacing or trimming to achieve specific dimensions. Processing differences include sheets being easier to cut and drill in flat planes, contrasted with rods that excel in lathe operations for producing round or complex profiles.

Cost Analysis: Nylon Sheet Versus Nylon Rod

Nylon sheets generally offer a lower cost per unit area compared to nylon rods due to their flat, thin form which reduces raw material waste during cutting. Nylon rods, being solid and cylindrical, often result in higher expenses for complex machining and greater material usage for equivalent surface coverage. Choosing nylon sheets over rods can lead to cost efficiency in applications requiring flat or large surface parts, while rods may incur higher costs justified only by specific structural or dimensional requirements.

Size and Thickness Variations

Nylon sheets offer extensive size and thickness variations, ranging from thin films of 0.5 mm up to thick panels exceeding 50 mm, ideal for large surface applications and custom cutting. Nylon rods typically come in diameters from 6 mm to 100 mm, providing uniform thickness ideal for machining into precision components. These dimensional differences make sheets preferable for broad, flat shapes, while rods suit round, solid parts requiring consistent cross-sectional profiles.

Surface Finish and Appearance

Nylon sheets typically feature a smoother surface finish ideal for applications requiring uniform appearance and precise machining, while nylon rods often exhibit a more textured surface due to the extrusion process. The polished finish of nylon sheets enhances aesthetic appeal and reduces friction, making them suitable for visible or sliding components. Nylon rods may require additional finishing, such as sanding or machining, to achieve a similar smoothness and visual quality as sheets.

Durability and Wear Resistance

Nylon sheets exhibit superior wear resistance due to their larger surface area, making them ideal for applications requiring broad, impact-resistant surfaces. Nylon rods provide exceptional durability in high-stress environments, maintaining structural integrity under continuous mechanical load. Both forms benefit from nylon's inherent resistance to abrasion, chemicals, and fatigue, but sheets better resist surface wear while rods excel in withstanding compressive forces.

Selecting the Right Nylon Form for Your Project

Nylon sheets offer a flat, versatile surface ideal for cutting, shaping, and machining into custom parts, making them suitable for applications requiring stability and uniform thickness such as gaskets, wear pads, and structural components. Nylon rods provide superior strength and are perfect for turning into shafts, pins, and bushings where durability and resistance to abrasion are critical. Choosing between nylon sheet and rod depends on project requirements including load-bearing capacity, machining complexity, and specific dimensional needs.

Nylon Sheet vs Nylon Rod Infographic

materialdif.com

materialdif.com