Nylon tubes are precision-engineered for fluid transfer in applications requiring flexibility and chemical resistance, while nylon pipes are designed for structural support and conveyance in industrial settings. Nylon tubes typically feature thinner walls and smoother surfaces for efficient flow, whereas nylon pipes have thicker walls to withstand higher pressures and mechanical stress. Choosing between nylon tube and pipe depends on the specific application needs, including pressure, flexibility, and durability.

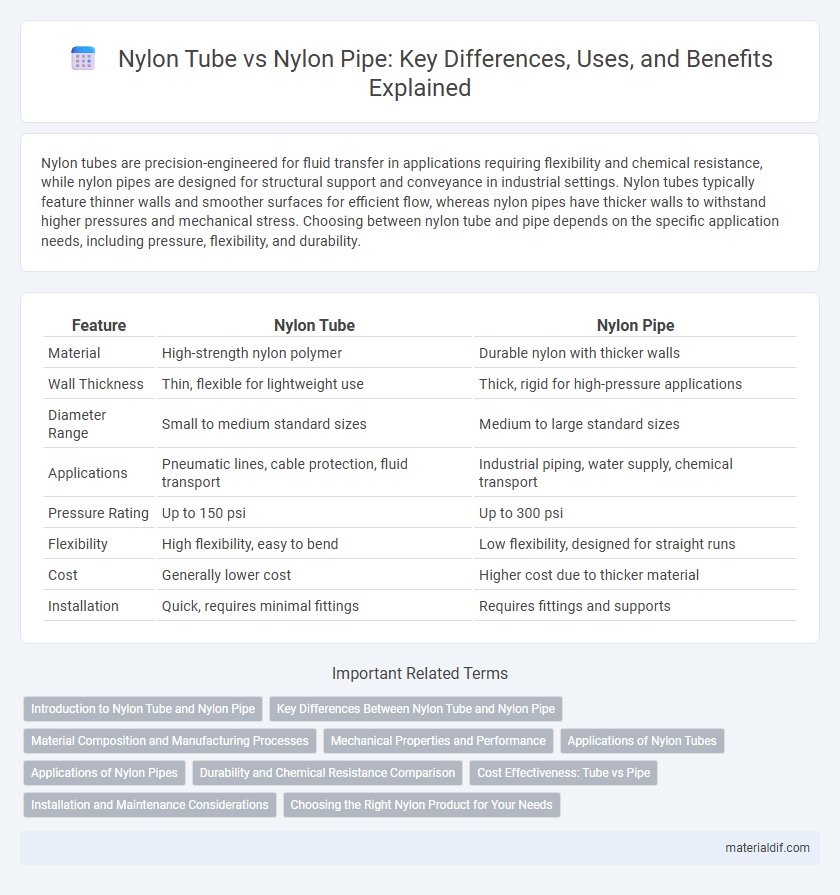

Table of Comparison

| Feature | Nylon Tube | Nylon Pipe |

|---|---|---|

| Material | High-strength nylon polymer | Durable nylon with thicker walls |

| Wall Thickness | Thin, flexible for lightweight use | Thick, rigid for high-pressure applications |

| Diameter Range | Small to medium standard sizes | Medium to large standard sizes |

| Applications | Pneumatic lines, cable protection, fluid transport | Industrial piping, water supply, chemical transport |

| Pressure Rating | Up to 150 psi | Up to 300 psi |

| Flexibility | High flexibility, easy to bend | Low flexibility, designed for straight runs |

| Cost | Generally lower cost | Higher cost due to thicker material |

| Installation | Quick, requires minimal fittings | Requires fittings and supports |

Introduction to Nylon Tube and Nylon Pipe

Nylon tubes are flexible and typically used for pneumatic and fluid transfer applications, offering excellent resistance to abrasion, chemicals, and impact. Nylon pipes, on the other hand, are rigid and designed for structural or conduit uses, providing high strength and durability under pressure. Both types of nylon products leverage the material's lightweight nature and corrosion resistance, making them ideal for industrial and mechanical settings.

Key Differences Between Nylon Tube and Nylon Pipe

Nylon tubes typically have thinner walls and are designed for precise fluid or gas flow control in applications like instrumentation and pneumatics, whereas nylon pipes feature thicker walls to withstand higher pressures in industrial plumbing or mechanical uses. Nylon tubes offer greater flexibility and smaller diameters suitable for intricate routing, while nylon pipes prioritize durability and structural strength for robust systems. The selection between nylon tube and pipe depends on pressure requirements, flexibility needs, and application-specific standards.

Material Composition and Manufacturing Processes

Nylon tubes are typically extruded from polyamide polymers with a focus on flexibility and precision, while nylon pipes often involve thicker walls and may incorporate additional fillers to enhance strength and durability. The manufacturing process for nylon tubes emphasizes seamless extrusion for consistent diameter and smooth surfaces, whereas nylon pipes can be produced using both extrusion and molding techniques to meet structural requirements. Material composition variations in nylon tubes prioritize lightweight and corrosion resistance, contrasting with nylon pipes designed for high pressure and mechanical stress applications.

Mechanical Properties and Performance

Nylon tubes offer superior flexibility and impact resistance compared to nylon pipes, making them ideal for applications requiring bending and vibration absorption. Nylon pipes, characterized by higher wall thickness, provide enhanced pressure resistance and tensile strength, suitable for fluid transport and structural support. Both materials exhibit excellent chemical and abrasion resistance, but the choice depends on mechanical demands such as load-bearing capacity and flexibility requirements.

Applications of Nylon Tubes

Nylon tubes are widely used in pneumatic and hydraulic systems due to their flexibility, lightweight properties, and resistance to abrasion and chemicals. Their applications include fuel lines, air hoses, and protective cable coverings in automotive, industrial machinery, and robotics sectors. Compared to rigid nylon pipes, nylon tubes offer superior adaptability in complex routing and vibration absorption, enhancing performance in dynamic environments.

Applications of Nylon Pipes

Nylon pipes are widely used in automotive fuel lines, compressed air systems, and chemical transfer applications due to their high resistance to abrasion, chemicals, and temperature variations. Their robust mechanical properties and superior flexibility enable efficient fluid conveyance in industrial machinery and pneumatic systems. Nylon pipes also find extensive use in irrigation and water supply networks where durability and corrosion resistance are critical.

Durability and Chemical Resistance Comparison

Nylon tubes typically offer superior flexibility and abrasion resistance, making them ideal for dynamic applications, while nylon pipes provide enhanced structural strength suitable for high-pressure environments. Both materials exhibit excellent chemical resistance against oils, solvents, and alkalis, but nylon pipes generally withstand harsher chemical exposure due to their thicker walls and manufacturing process. Durability in nylon tubes is enhanced by their ability to absorb impacts without cracking, whereas nylon pipes excel in load-bearing scenarios where rigidity and dimensional stability are critical.

Cost Effectiveness: Tube vs Pipe

Nylon tubes generally offer greater cost effectiveness than nylon pipes due to their thinner walls and lighter weight, which reduce material costs and shipping expenses. Nylon pipes tend to have thicker walls designed for higher pressure applications, increasing both initial purchase and installation costs. Choosing nylon tubes for low-pressure or lightweight tasks can significantly lower overall project expenses while maintaining adequate durability.

Installation and Maintenance Considerations

Nylon tube offers flexibility and ease of cutting for custom lengths during installation, making it ideal for applications requiring precise routing and complex bends. Nylon pipe provides higher pressure resistance and durability, demanding specialized fittings and tools for proper assembly, which can affect maintenance complexity. Regular inspection and cleaning are essential for both materials to prevent blockages and ensure long-term performance in fluid handling systems.

Choosing the Right Nylon Product for Your Needs

Nylon tubes and nylon pipes differ primarily in wall thickness, diameter, and flexibility, with tubes offering thinner walls and greater flexibility ideal for precision applications like fluid transfer or protective wiring. Nylon pipes feature thicker walls and higher pressure resistance, making them suitable for industrial plumbing and structural uses where durability is crucial. Selecting between nylon tube and pipe depends on specific requirements such as pressure ratings, flexibility needs, and environmental exposure to ensure optimal performance and longevity.

Nylon Tube vs Nylon Pipe Infographic

materialdif.com

materialdif.com