UV-stabilized nylon offers enhanced durability and resistance to sun damage, preventing discoloration and degradation from prolonged exposure to ultraviolet rays. Non-UV-stabilized nylon tends to weaken and become brittle over time when exposed to sunlight, reducing its lifespan and performance. Choosing UV-stabilized nylon ensures longer-lasting strength and maintains the material's integrity in outdoor applications.

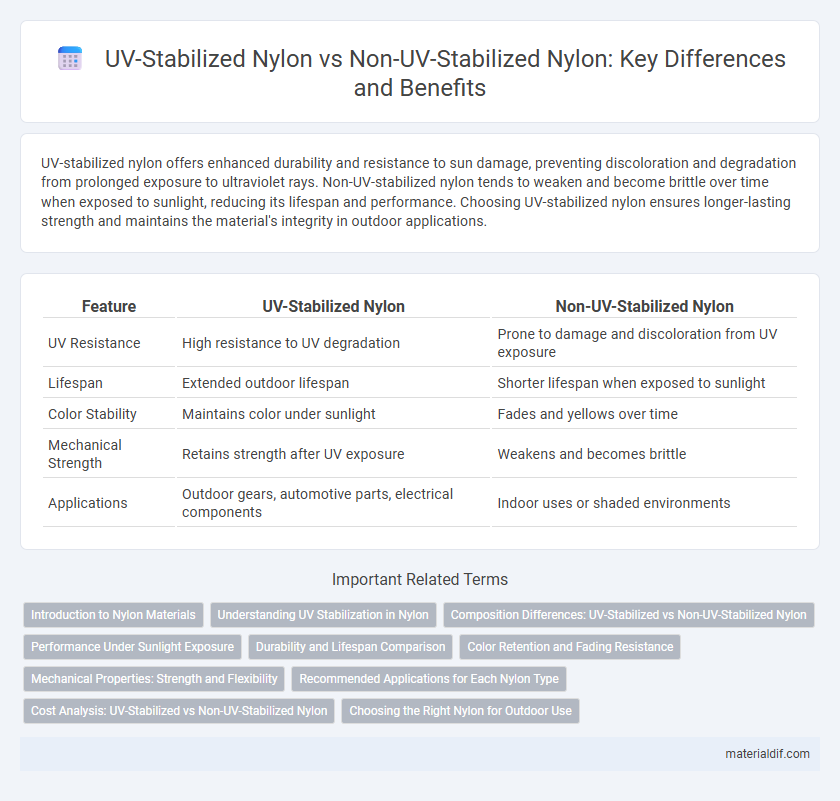

Table of Comparison

| Feature | UV-Stabilized Nylon | Non-UV-Stabilized Nylon |

|---|---|---|

| UV Resistance | High resistance to UV degradation | Prone to damage and discoloration from UV exposure |

| Lifespan | Extended outdoor lifespan | Shorter lifespan when exposed to sunlight |

| Color Stability | Maintains color under sunlight | Fades and yellows over time |

| Mechanical Strength | Retains strength after UV exposure | Weakens and becomes brittle |

| Applications | Outdoor gears, automotive parts, electrical components | Indoor uses or shaded environments |

Introduction to Nylon Materials

UV-stabilized nylon incorporates additives that protect polymer chains from degradation caused by ultraviolet radiation, significantly enhancing durability and color retention in outdoor applications. Non-UV-stabilized nylon lacks these protective agents, leading to faster deterioration, discoloration, and loss of mechanical properties when exposed to sunlight over time. Choosing UV-stabilized nylon for products such as automotive components, outdoor fabrics, and electrical insulators ensures prolonged performance and extended service life in harsh UV environments.

Understanding UV Stabilization in Nylon

UV-stabilized nylon incorporates additives such as UV absorbers and hindered amine light stabilizers (HALS) to protect polymer chains from degradation caused by ultraviolet radiation. This stabilization significantly enhances nylon's resistance to color fading, cracking, and loss of mechanical properties when exposed to prolonged sunlight. Non-UV-stabilized nylon lacks these protective compounds, resulting in rapid deterioration under UV exposure and reduced material lifespan in outdoor applications.

Composition Differences: UV-Stabilized vs Non-UV-Stabilized Nylon

UV-stabilized nylon incorporates specific additives such as UV absorbers, hindered amine light stabilizers (HALS), and antioxidants that protect polymer chains from photodegradation caused by ultraviolet radiation. Non-UV-stabilized nylon lacks these protective compounds, making it more susceptible to discoloration, loss of mechanical properties, and surface cracking when exposed to sunlight. The compositional difference directly impacts the longevity and performance of nylon in outdoor applications, with UV-stabilized variants offering enhanced durability and weather resistance.

Performance Under Sunlight Exposure

UV-stabilized nylon resists degradation from prolonged sunlight exposure by incorporating UV absorbers or stabilizers, enhancing durability and maintaining mechanical strength over time. Non-UV-stabilized nylon tends to degrade rapidly under UV radiation, leading to discoloration, brittleness, and reduced tensile strength. Choosing UV-stabilized nylon significantly extends the material's lifespan in outdoor applications exposed to direct sunlight.

Durability and Lifespan Comparison

UV-stabilized nylon exhibits significantly enhanced durability and a longer lifespan compared to non-UV-stabilized nylon, as it resists degradation caused by ultraviolet radiation. The incorporation of UV stabilizers prevents polymer chain breakdown, maintaining mechanical strength and flexibility under prolonged sun exposure. Non-UV-stabilized nylon tends to become brittle, discolor, and lose tensile strength quickly when subjected to outdoor conditions, reducing its functional lifespan.

Color Retention and Fading Resistance

UV-stabilized nylon incorporates additives that significantly enhance color retention and minimize fading when exposed to prolonged sunlight, preserving vibrant hues over time. Non-UV-stabilized nylon lacks these protective agents, resulting in quicker color degradation and noticeable fading under UV radiation. Manufacturers often recommend UV-stabilized variants for outdoor applications to ensure longer-lasting aesthetics and durability.

Mechanical Properties: Strength and Flexibility

UV-stabilized nylon maintains superior mechanical properties such as tensile strength and flexibility when exposed to prolonged sunlight, preventing degradation and brittleness. Non-UV-stabilized nylon experiences significant loss in strength and becomes more prone to cracking and loss of flexibility due to ultraviolet radiation exposure. The enhanced durability of UV-stabilized nylon makes it ideal for outdoor applications requiring long-term mechanical performance.

Recommended Applications for Each Nylon Type

UV-stabilized nylon is recommended for outdoor applications such as automotive parts, electrical components, and outdoor furniture where prolonged exposure to sunlight can cause degradation. Non-UV-stabilized nylon is suitable for indoor uses like textiles, consumer goods, and machinery parts where minimal UV exposure occurs. Selecting the appropriate nylon type enhances product durability and performance in specific environmental conditions.

Cost Analysis: UV-Stabilized vs Non-UV-Stabilized Nylon

UV-stabilized nylon typically incurs higher manufacturing costs due to the incorporation of specialized additives that enhance resistance to ultraviolet radiation, extending product lifespan in outdoor applications. Non-UV-stabilized nylon, while cheaper upfront, often leads to increased replacement expenses and maintenance costs caused by degradation such as brittleness and discoloration when exposed to prolonged sunlight. Evaluating total cost of ownership favors UV-stabilized nylon in environments with significant UV exposure, where durability and reduced downtime justify the initial investment.

Choosing the Right Nylon for Outdoor Use

UV-stabilized nylon resists degradation from ultraviolet rays, enhancing durability and maintaining strength in outdoor environments, whereas non-UV-stabilized nylon degrades quickly, leading to brittleness and color fading. Selecting UV-stabilized nylon is essential for applications in outdoor gear, marine equipment, and automotive components exposed to sunlight. This ensures longer lifespan, weather resistance, and cost-effectiveness compared to conventional nylon.

UV-stabilized nylon vs Non-UV-stabilized nylon Infographic

materialdif.com

materialdif.com