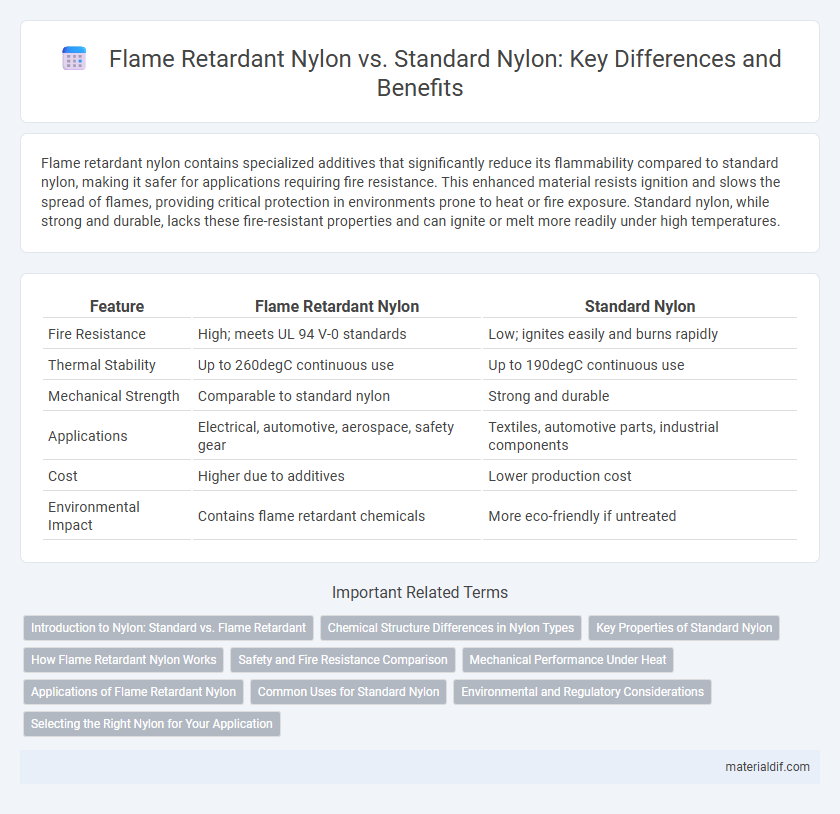

Flame retardant nylon contains specialized additives that significantly reduce its flammability compared to standard nylon, making it safer for applications requiring fire resistance. This enhanced material resists ignition and slows the spread of flames, providing critical protection in environments prone to heat or fire exposure. Standard nylon, while strong and durable, lacks these fire-resistant properties and can ignite or melt more readily under high temperatures.

Table of Comparison

| Feature | Flame Retardant Nylon | Standard Nylon |

|---|---|---|

| Fire Resistance | High; meets UL 94 V-0 standards | Low; ignites easily and burns rapidly |

| Thermal Stability | Up to 260degC continuous use | Up to 190degC continuous use |

| Mechanical Strength | Comparable to standard nylon | Strong and durable |

| Applications | Electrical, automotive, aerospace, safety gear | Textiles, automotive parts, industrial components |

| Cost | Higher due to additives | Lower production cost |

| Environmental Impact | Contains flame retardant chemicals | More eco-friendly if untreated |

Introduction to Nylon: Standard vs. Flame Retardant

Nylon is a versatile synthetic polymer widely used for its strength, flexibility, and durability in various industries. Standard nylon offers excellent mechanical properties but lacks inherent fire resistance, making it less suitable for applications requiring high safety standards. Flame retardant nylon incorporates specialized additives that enhance its resistance to ignition and flame spread, meeting stringent fire safety regulations without compromising the material's structural integrity.

Chemical Structure Differences in Nylon Types

Flame retardant nylon incorporates chemical additives such as halogenated compounds or phosphorus-based agents that alter its polymer chains to enhance fire resistance, unlike standard nylon which lacks these modifications. The molecular structure of flame retardant nylon includes flame-inhibiting elements that disrupt combustion processes, resulting in reduced flammability and slower ignition. Standard nylon's polymer backbone remains unmodified, consisting primarily of repeating amide linkages without integrated flame retardant components.

Key Properties of Standard Nylon

Standard nylon exhibits high tensile strength, excellent abrasion resistance, and good elasticity, making it suitable for a wide range of industrial and consumer applications. Its moisture absorption properties contribute to dimensional stability but can affect electrical insulation performance. Compared to flame retardant nylon, standard nylon has lower flame resistance and melts at temperatures around 215degC to 265degC, limiting its use in high-temperature or fire-prone environments.

How Flame Retardant Nylon Works

Flame retardant nylon incorporates chemical additives or copolymers that interrupt the combustion process by promoting char formation and reducing flammable gas release. This modification enhances thermal stability and lowers the material's flammability compared to standard nylon, which burns readily and melts under high heat. These properties make flame retardant nylon critical in applications requiring increased fire resistance and safety compliance.

Safety and Fire Resistance Comparison

Flame retardant nylon incorporates chemical additives that significantly reduce flammability, enabling it to self-extinguish when exposed to fire, unlike standard nylon which ignites quickly and supports combustion. This enhanced fire resistance ensures improved safety in applications requiring strict fire codes, such as electrical enclosures and automotive components. Flame retardant nylon also releases fewer toxic fumes during combustion, minimizing health hazards compared to standard nylon.

Mechanical Performance Under Heat

Flame retardant nylon maintains superior mechanical integrity at elevated temperatures compared to standard nylon, which tends to degrade and lose strength more rapidly when exposed to heat. Its enhanced thermal stability ensures consistent tensile strength and impact resistance during prolonged thermal exposure, making it ideal for high-temperature applications. This improved performance results from specialized additives that inhibit combustion and reduce heat-induced polymer degradation.

Applications of Flame Retardant Nylon

Flame retardant nylon is widely used in electrical and automotive industries due to its enhanced resistance to ignition and reduced smoke emission, ensuring safety in high-heat environments. It is commonly found in wire insulation, connectors, and housings where compliance with fire safety standards is critical. Compared to standard nylon, flame retardant nylon offers superior durability and protection in applications requiring stringent fire retardancy.

Common Uses for Standard Nylon

Standard nylon is widely used in textile manufacturing for clothing, carpets, and upholstery due to its strength, elasticity, and abrasion resistance. It is also common in industrial applications such as automotive parts, fishing lines, and ropes because of its durability and chemical resistance. Unlike flame retardant nylon, standard nylon lacks inherent fire resistance, making it less suitable for environments with stringent fire safety requirements.

Environmental and Regulatory Considerations

Flame retardant nylon incorporates chemical additives that enhance fire resistance but may introduce environmental concerns due to potential toxicity and challenges in recycling. Standard nylon, while lacking these additives, typically offers better recyclability and a lower environmental impact throughout its lifecycle. Regulatory standards such as REACH and RoHS impose strict limits on flame retardant chemicals to mitigate environmental and health risks associated with their use in nylon materials.

Selecting the Right Nylon for Your Application

Flame retardant nylon is engineered with additives that significantly reduce flammability, making it ideal for electrical components, automotive parts, and industrial applications requiring enhanced fire resistance. Standard nylon offers excellent mechanical strength, chemical resistance, and abrasion resistance, suitable for general-purpose uses like textiles, gears, and molded parts. Selecting between flame retardant and standard nylon depends on application-specific factors such as exposure to heat, fire safety requirements, and regulatory compliance standards.

Flame Retardant Nylon vs Standard Nylon Infographic

materialdif.com

materialdif.com