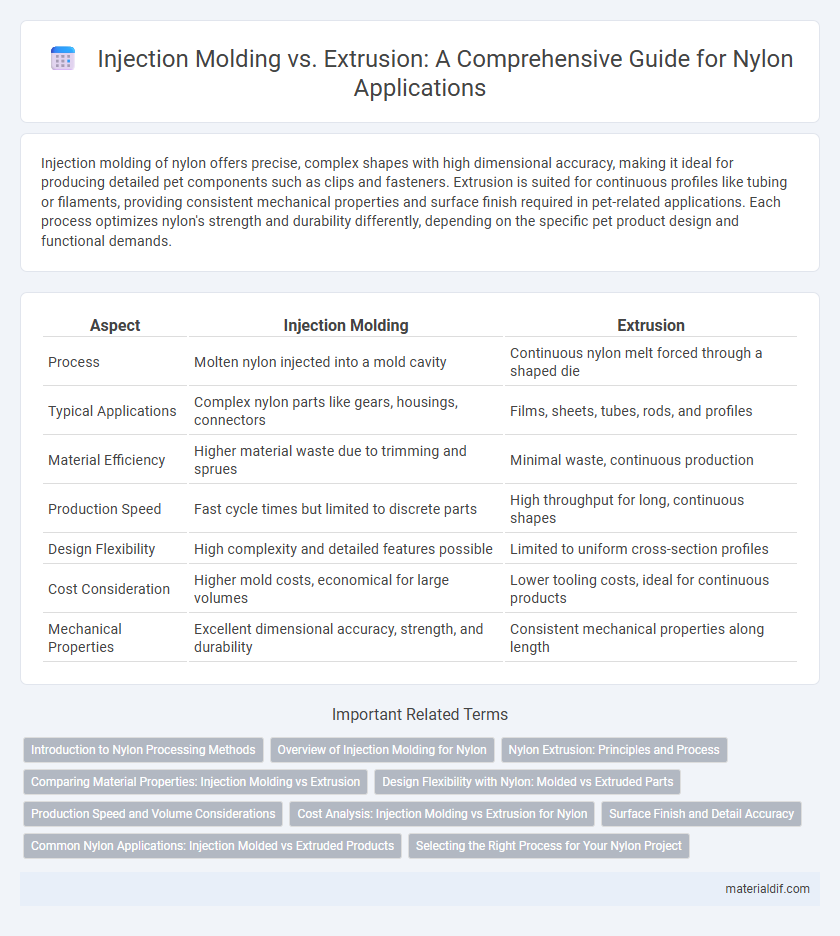

Injection molding of nylon offers precise, complex shapes with high dimensional accuracy, making it ideal for producing detailed pet components such as clips and fasteners. Extrusion is suited for continuous profiles like tubing or filaments, providing consistent mechanical properties and surface finish required in pet-related applications. Each process optimizes nylon's strength and durability differently, depending on the specific pet product design and functional demands.

Table of Comparison

| Aspect | Injection Molding | Extrusion |

|---|---|---|

| Process | Molten nylon injected into a mold cavity | Continuous nylon melt forced through a shaped die |

| Typical Applications | Complex nylon parts like gears, housings, connectors | Films, sheets, tubes, rods, and profiles |

| Material Efficiency | Higher material waste due to trimming and sprues | Minimal waste, continuous production |

| Production Speed | Fast cycle times but limited to discrete parts | High throughput for long, continuous shapes |

| Design Flexibility | High complexity and detailed features possible | Limited to uniform cross-section profiles |

| Cost Consideration | Higher mold costs, economical for large volumes | Lower tooling costs, ideal for continuous products |

| Mechanical Properties | Excellent dimensional accuracy, strength, and durability | Consistent mechanical properties along length |

Introduction to Nylon Processing Methods

Injection molding of nylon offers precise control over complex shapes and tight tolerances, making it ideal for producing detailed components such as gears and automotive parts. Extrusion processes focus on creating continuous profiles, such as tubing, rods, and sheets, benefiting applications that require uniform cross-sections and consistent mechanical properties. Understanding the distinct advantages of nylon injection molding versus extrusion enables manufacturers to select the optimal method for specific product requirements and performance standards.

Overview of Injection Molding for Nylon

Injection molding for nylon enables the production of complex, high-strength components with precise dimensions and excellent surface finish, making it ideal for automotive, electrical, and consumer product applications. This process involves melting nylon pellets and injecting the molten polymer into a mold cavity under high pressure, ensuring rapid cooling and solidification for consistent quality. Injection molding supports intricate geometries and fine details, offering superior mechanical properties compared to extrusion, which is better suited for continuous profiles like tubes or sheets.

Nylon Extrusion: Principles and Process

Nylon extrusion involves melting nylon resin and forcing it through a shaped die to create continuous profiles such as rods, tubes, and films, enabling precise control of dimensions and mechanical properties. This process enhances the material's strength and flexibility by aligning polymer chains during cooling, making it ideal for applications requiring uniform cross-sections and consistent surface finish. Nylon extrusion supports customization in industries like automotive and electrical insulation, where durability and resistance to wear are critical.

Comparing Material Properties: Injection Molding vs Extrusion

Injection molding of nylon offers superior dimensional accuracy and surface finish compared to extrusion, making it ideal for complex, precision parts. Extruded nylon typically exhibits enhanced mechanical strength and flexibility due to continuous polymer orientation, which benefits applications requiring wear resistance. Thermal stability and moisture absorption rates vary, with injection-molded nylon often displaying slightly higher moisture uptake that can affect mechanical properties in humid environments.

Design Flexibility with Nylon: Molded vs Extruded Parts

Injection molding of nylon offers superior design flexibility, enabling the creation of complex geometries, intricate details, and integrated features that are challenging to achieve with extrusion. Extruded nylon parts typically have uniform cross-sections, limiting customization but providing consistent mechanical properties and cost-effective high-volume production. Molded nylon components excel in applications requiring precise dimensions and aesthetic refinement, while extruded parts are ideal for structural profiles and continuous shapes.

Production Speed and Volume Considerations

Injection molding of nylon offers rapid production cycles and high-volume output suitable for complex, high-precision parts, making it ideal for automotive and consumer goods industries. Extrusion enables continuous production of long nylon profiles with consistent cross-sections, favored for tubing, sheets, and filaments where high volume and steady throughput are essential. Production speed in injection molding is generally faster per individual part, while extrusion excels in generating large quantities of uniform nylon products continuously.

Cost Analysis: Injection Molding vs Extrusion for Nylon

Injection molding for nylon typically incurs higher initial tooling costs due to complex molds but offers lower per-unit expenses in large production runs, making it cost-effective for high-volume parts with intricate geometries. Extrusion presents lower startup costs with simpler die designs, ideal for continuous nylon profiles and long-length products, but higher material waste and slower production speeds can increase costs for complex shapes. Analyzing cost efficiency depends on production volume, part complexity, and material usage, with injection molding favored in mass manufacturing and extrusion preferred for simpler, linear nylon components.

Surface Finish and Detail Accuracy

Injection molding of nylon offers superior surface finish and high detail accuracy due to precise control of mold design and processing parameters, making it ideal for complex, intricate components. Extrusion of nylon produces continuous profiles with uniform cross-sections but typically has rougher surface texture and lower dimensional precision compared to injection molding. For applications requiring smooth surfaces and detailed features, injection molding provides significant advantages over extrusion in nylon processing.

Common Nylon Applications: Injection Molded vs Extruded Products

Injection molding of nylon is ideal for producing complex, precision components such as automotive parts, electrical housings, and consumer goods due to its ability to create detailed shapes with tight tolerances. Extrusion is commonly used for manufacturing continuous profiles like tubing, rods, and sheets, offering uniform cross-sections for industrial, packaging, and construction applications. Both processes leverage nylon's strength, chemical resistance, and thermal stability but differ in product form and application scope.

Selecting the Right Process for Your Nylon Project

Injection molding offers precise, intricate shapes for nylon applications, ideal for high-volume production of complex components like gears and fittings. Extrusion is better suited for continuous profiles such as tubes, sheets, and rods, providing consistent cross-sections and excellent mechanical properties. Selecting the right process depends on project requirements including part geometry, production volume, and desired surface finish.

Injection Molding vs Extrusion (Nylon Applications) Infographic

materialdif.com

materialdif.com