Nylon pellets and nylon granules both serve as raw materials for manufacturing, but they differ primarily in size and processing applications. Nylon pellets are typically larger, uniform beads used in injection molding, whereas nylon granules are smaller and often better suited for extrusion processes. Choosing between pellets and granules depends on the specific requirements of the production method and desired material properties.

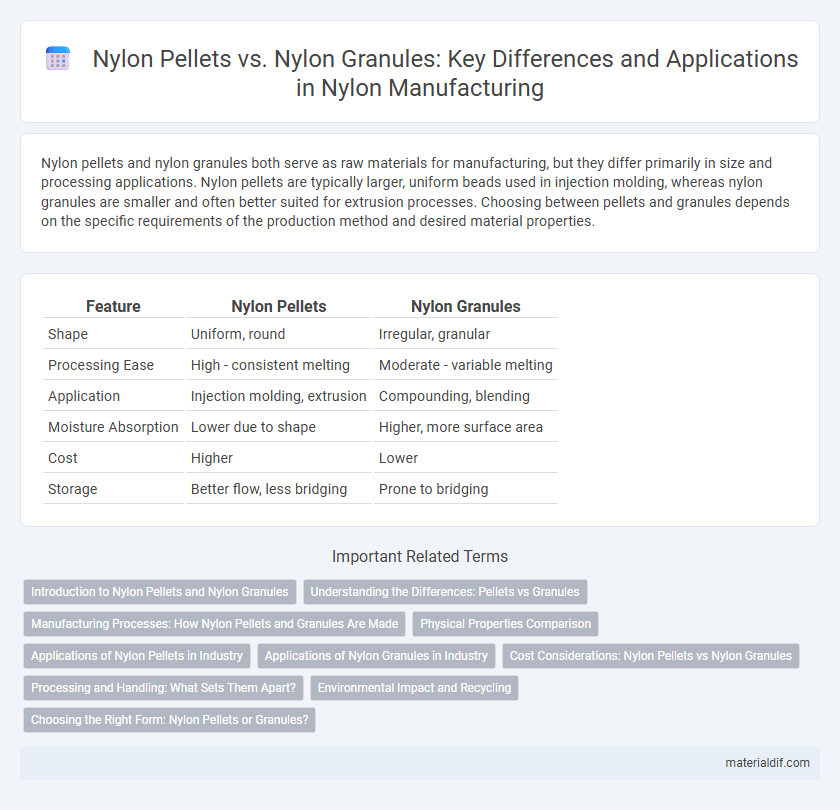

Table of Comparison

| Feature | Nylon Pellets | Nylon Granules |

|---|---|---|

| Shape | Uniform, round | Irregular, granular |

| Processing Ease | High - consistent melting | Moderate - variable melting |

| Application | Injection molding, extrusion | Compounding, blending |

| Moisture Absorption | Lower due to shape | Higher, more surface area |

| Cost | Higher | Lower |

| Storage | Better flow, less bridging | Prone to bridging |

Introduction to Nylon Pellets and Nylon Granules

Nylon pellets and nylon granules are primary forms of raw nylon used in manufacturing, with pellets typically being small, cylindrical shapes while granules are irregularly shaped particles. Both forms serve as feedstock for injection molding, extrusion, and other plastic processing techniques, offering excellent mechanical strength, chemical resistance, and thermal stability. Selecting between nylon pellets and granules depends on processing requirements, flow properties, and equipment compatibility to achieve optimal product performance.

Understanding the Differences: Pellets vs Granules

Nylon pellets and nylon granules differ primarily in size and application; pellets are typically larger, uniform, and ideal for injection molding processes, while granules are finer and better suited for extrusion or compounding. The physical form of nylon affects melting behavior, flow rate, and ease of handling during manufacturing, impacting product consistency and mechanical properties. Selecting between nylon pellets and granules depends on the specific requirements of the production technique and end-use performance criteria.

Manufacturing Processes: How Nylon Pellets and Granules Are Made

Nylon pellets are produced through an extrusion process where molten nylon is forced through a die and then cooled to form small cylindrical shapes, ensuring consistent size and ease of handling in manufacturing. Nylon granules result from pellet pulverization or direct granulation, creating smaller, irregularly shaped particles favored for rapid melting and uniform mixing in injection molding. Both forms undergo controlled polymerization and drying stages to maintain chemical integrity and moisture-free quality essential for high-performance applications.

Physical Properties Comparison

Nylon pellets typically exhibit uniform size and shape which contribute to consistent melting behavior and ease of processing in injection molding applications. Nylon granules often have irregular shapes and variable sizes, leading to a broader melting temperature range and potentially less predictable flow properties during extrusion. Both forms retain similar tensile strength and thermal resistance, but pellets generally provide better dimensional stability and surface finish in final molded products.

Applications of Nylon Pellets in Industry

Nylon pellets are widely used in injection molding and extrusion processes across automotive, electronics, and consumer goods industries due to their uniform size and ease of handling. Their consistent melting properties enable precise manufacturing of high-strength, wear-resistant components such as gears, bearings, and connectors. Unlike nylon granules, these pellets facilitate faster melting and improved flow characteristics, optimizing production efficiency and product quality in industrial applications.

Applications of Nylon Granules in Industry

Nylon granules are widely utilized in the automotive and electronics industries due to their superior melt flow and consistent polymer chain length, which enhance precision molding and mechanical strength. These granules offer better dimensional stability and thermal resistance compared to pellets, making them ideal for producing high-performance components such as gears, connectors, and housings. Their uniform size and shape improve feeding efficiency in injection molding machines, resulting in faster production cycles and reduced material waste.

Cost Considerations: Nylon Pellets vs Nylon Granules

Nylon pellets typically offer a lower cost per unit due to their uniform size and ease of processing in automated machinery, reducing production downtime. Nylon granules may incur higher expenses because of inconsistent shape and size, leading to potential challenges in melting and molding that increase energy consumption and waste. Manufacturers often choose nylon pellets over granules to optimize cost-efficiency in large-scale production environments.

Processing and Handling: What Sets Them Apart?

Nylon pellets offer consistent size and shape, making them ideal for automated feeding systems in injection molding, while nylon granules, with their irregular form, may require slower processing speeds to ensure uniform melting. The uniformity of pellets reduces bridging and ensures smooth flow in hoppers, contrasting with the potential for granules to clump and cause feeding interruptions. Handling pellets typically results in less dust generation than granules, enhancing workplace safety and reducing material loss during transport and processing.

Environmental Impact and Recycling

Nylon pellets and nylon granules differ primarily in size, with pellets being smaller and more uniform, which can influence their environmental impact during production and recycling processes. Nylon pellets typically melt more efficiently in recycling facilities, reducing energy consumption and lowering carbon emissions compared to larger granules that may require additional processing. Recycling efforts benefit from the standardized size of nylon pellets, facilitating improved sorting and reprocessing, thus minimizing waste and promoting sustainable material reuse within the nylon manufacturing industry.

Choosing the Right Form: Nylon Pellets or Granules?

Nylon pellets and nylon granules differ primarily in size, with pellets being larger, typically 3-5 mm, while granules are finer, around 1-3 mm. Choosing the right form depends on the molding process; pellets are ideal for injection molding due to better flow and uniform melting, whereas granules suit extrusion and compounding applications requiring more consistent blending and faster melting. Understanding the specific manufacturing requirements and processing equipment ensures optimal material performance and production efficiency with nylon.

Nylon Pellets vs Nylon Granules Infographic

materialdif.com

materialdif.com