Nylon textile offers a flexible, durable, and breathable material ideal for pet products such as collars, leashes, and harnesses, providing comfort and strength. Nylon film, on the other hand, is a thin, impermeable layer primarily used for protective coatings and waterproof barriers in pet accessories. The choice between nylon textile and nylon film depends on the need for flexibility and breathability versus water resistance and durability.

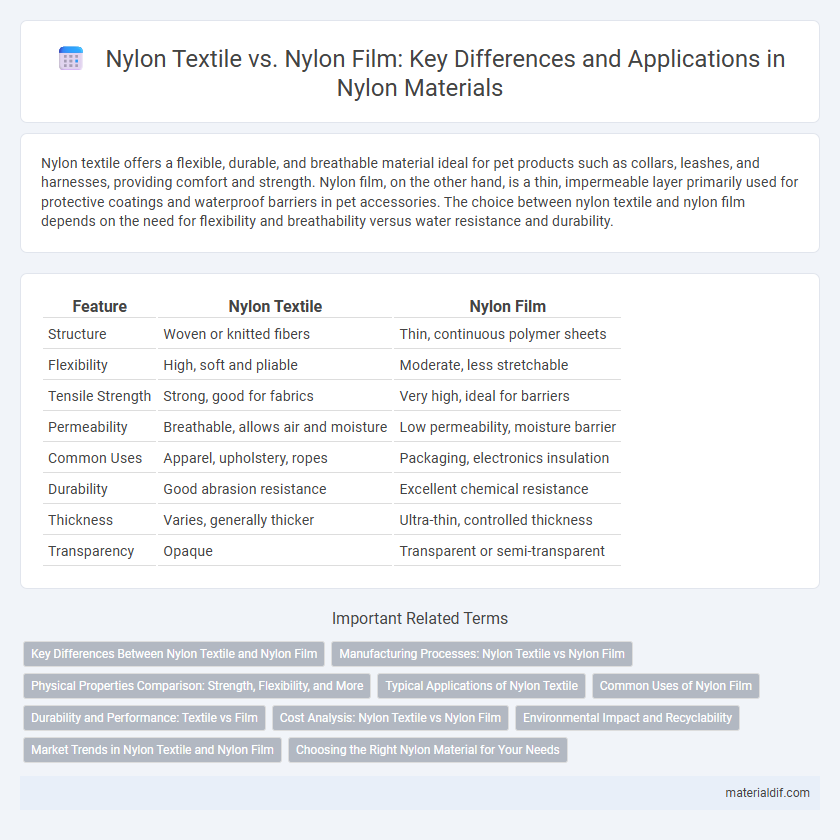

Table of Comparison

| Feature | Nylon Textile | Nylon Film |

|---|---|---|

| Structure | Woven or knitted fibers | Thin, continuous polymer sheets |

| Flexibility | High, soft and pliable | Moderate, less stretchable |

| Tensile Strength | Strong, good for fabrics | Very high, ideal for barriers |

| Permeability | Breathable, allows air and moisture | Low permeability, moisture barrier |

| Common Uses | Apparel, upholstery, ropes | Packaging, electronics insulation |

| Durability | Good abrasion resistance | Excellent chemical resistance |

| Thickness | Varies, generally thicker | Ultra-thin, controlled thickness |

| Transparency | Opaque | Transparent or semi-transparent |

Key Differences Between Nylon Textile and Nylon Film

Nylon textile and nylon film differ primarily in structure and application; nylon textile is a woven or knitted fabric used extensively in apparel, upholstery, and industrial products, while nylon film is a thin, flexible sheet utilized in packaging, electronics, and barrier layers. Nylon textile provides breathability, durability, and elasticity, making it ideal for wearable and functional textiles, whereas nylon film offers excellent moisture resistance, chemical stability, and mechanical strength for protective and insulating purposes. These distinctions in physical form and performance characteristics guide the specific use cases and manufacturing processes of nylon textile versus nylon film.

Manufacturing Processes: Nylon Textile vs Nylon Film

Nylon textile manufacturing involves fiber extrusion, spinning, drawing, and weaving or knitting to produce flexible and durable fabrics used in apparel and industrial applications. Nylon film is produced through melt extrusion or solution casting followed by biaxial orientation to create thin, transparent, and high-strength sheets ideal for packaging and electrical insulation. The key difference lies in the post-extrusion processing where textiles require fiber manipulation and films undergo controlled stretching to achieve distinct structural and functional properties.

Physical Properties Comparison: Strength, Flexibility, and More

Nylon textile exhibits superior flexibility and breathability compared to nylon film, making it ideal for apparel and soft goods, while nylon film offers greater tensile strength and excellent barrier properties suitable for packaging applications. The molecular orientation in nylon film results in higher density and hardness, contrasting with the porous, woven structure of nylon textile that enhances wear resistance and stretchability. Both materials share high abrasion resistance and chemical stability, yet their distinct physical forms define their specific performance advantages in industrial and consumer products.

Typical Applications of Nylon Textile

Nylon textile is widely used in apparel manufacturing, including activewear, hosiery, and lingerie, due to its high elasticity, durability, and moisture-wicking properties. In industrial applications, nylon textiles serve in conveyor belts, parachutes, and tire cords, providing exceptional strength and abrasion resistance. Compared to nylon film, which is primarily used for packaging and protective barriers, nylon textile offers superior flexibility and breathability for wearable and structural uses.

Common Uses of Nylon Film

Nylon film is widely used in packaging applications, including food wraps, vacuum-sealed bags, and pharmaceutical packaging, due to its excellent barrier properties and durability. It also finds common use in industrial applications such as electrical insulation, flexible circuits, and protective laminates. Unlike nylon textile, which is primarily used in apparel and upholstery, nylon film excels in environments requiring moisture resistance and mechanical strength.

Durability and Performance: Textile vs Film

Nylon textile offers superior flexibility and breathability, making it ideal for applications requiring durability under tension and movement, such as apparel and upholstery. Nylon film provides excellent strength and chemical resistance with a smooth, impermeable surface, preferred for packaging and industrial uses. While textile excels in wear resistance and moisture management, film outperforms in barrier properties and puncture resistance.

Cost Analysis: Nylon Textile vs Nylon Film

Nylon textile typically incurs higher production costs due to complex weaving and finishing processes, while nylon film benefits from more streamlined extrusion and casting techniques that reduce manufacturing expenses. Raw material consumption differs, with nylon textile requiring more fiber input, contributing to greater overall material costs compared to the thinner, more uniform nylon films. Economies of scale in film production often lead to lower per-unit costs, making nylon film a more cost-effective option for applications requiring lightweight and flexible materials.

Environmental Impact and Recyclability

Nylon textile production typically generates higher carbon emissions and water usage compared to nylon film manufacturing, due to the more complex fiber spinning and weaving processes. Nylon films, often used in packaging, have a higher potential for mechanical recycling but face challenges in chemical recycling because of additives and multi-layer structures. Both forms struggle with biodegradability, emphasizing the need for improved closed-loop recycling technologies to reduce environmental impact.

Market Trends in Nylon Textile and Nylon Film

The nylon textile market is expanding rapidly due to growing demand in apparel, automotive, and industrial sectors driven by its durability and elasticity. In contrast, the nylon film segment shows steady growth fueled by increasing applications in packaging, electrical insulation, and barrier films. Advanced manufacturing technologies and sustainability initiatives are shaping market trends for both nylon textile and nylon film industries.

Choosing the Right Nylon Material for Your Needs

Nylon textile offers flexibility, breathability, and durability, making it ideal for apparel, upholstery, and outdoor gear, while nylon film provides excellent tensile strength, chemical resistance, and moisture barriers suited for packaging, electrical insulation, and industrial applications. Selecting the right nylon material depends on the specific use case requirements such as mechanical properties, environmental exposure, and fabrication processes. Understanding the differences in texture, thickness, and performance characteristics ensures optimal material choice for cost-effectiveness and functionality.

Nylon Textile vs Nylon Film Infographic

materialdif.com

materialdif.com