Nylon abrasion testing evaluates the material's resistance to surface wear and friction, ensuring durability in applications subject to constant rubbing or scraping. Tensile testing measures nylon's strength and elasticity by determining the maximum force it can withstand before breaking. Comparing these tests highlights nylon's performance under different stress conditions, guiding optimal material selection for pet products requiring both toughness and flexibility.

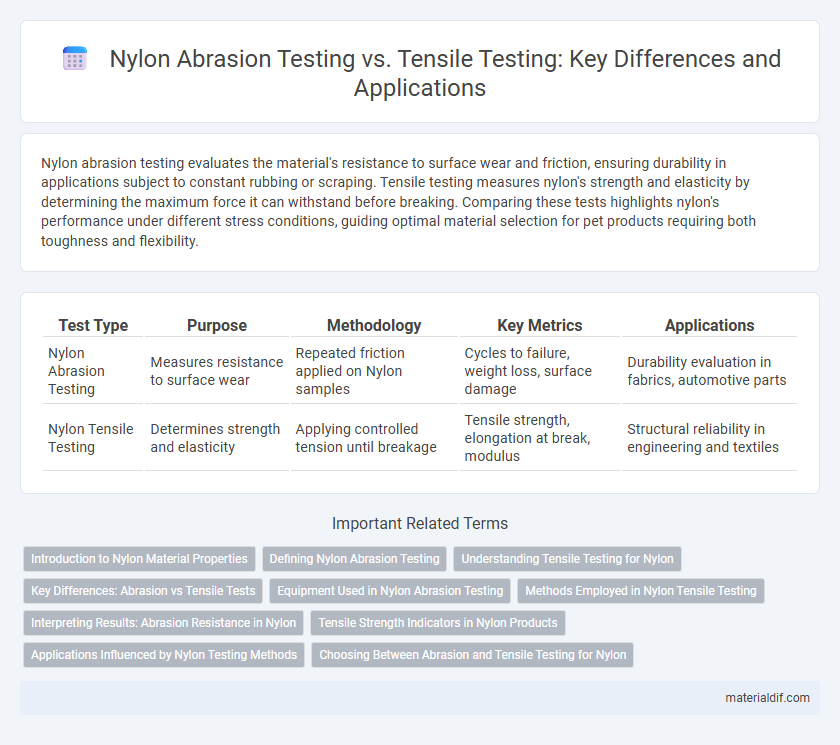

Table of Comparison

| Test Type | Purpose | Methodology | Key Metrics | Applications |

|---|---|---|---|---|

| Nylon Abrasion Testing | Measures resistance to surface wear | Repeated friction applied on Nylon samples | Cycles to failure, weight loss, surface damage | Durability evaluation in fabrics, automotive parts |

| Nylon Tensile Testing | Determines strength and elasticity | Applying controlled tension until breakage | Tensile strength, elongation at break, modulus | Structural reliability in engineering and textiles |

Introduction to Nylon Material Properties

Nylon exhibits exceptional durability and elasticity, making abrasion testing essential for assessing its resistance to surface wear in applications like textiles and automotive parts. Tensile testing measures nylon's strength and elongation under tension, providing critical data about its load-bearing capacity and flexibility. Understanding these properties helps manufacturers optimize nylon formulations for performance and longevity in various industrial uses.

Defining Nylon Abrasion Testing

Nylon abrasion testing measures the material's resistance to surface wear and friction, crucial for applications requiring durability against continuous contact and rubbing. This test evaluates how well nylon maintains integrity under mechanical stress from repeated abrasion cycles, affecting its lifespan in textiles, automotive parts, and industrial components. Unlike tensile testing, which assesses strength and elongation under tension, abrasion testing focuses on surface durability and resistance to material loss through friction.

Understanding Tensile Testing for Nylon

Tensile testing for nylon evaluates its strength and elasticity by measuring the maximum stress it can withstand before breaking, providing critical data on elongation and tensile modulus. This test helps determine nylon's suitability for applications requiring durability and flexibility under load. Unlike abrasion testing, which assesses surface wear resistance, tensile testing focuses on the material's ability to resist deformation and failure under tensile forces.

Key Differences: Abrasion vs Tensile Tests

Nylon abrasion testing evaluates the material's surface resistance to wear and friction, measuring durability under repeated contact and rubbing. Tensile testing of nylon measures its strength by assessing the maximum force the material can withstand before breaking, focusing on elasticity and elongation properties. The key difference lies in abrasion tests targeting surface resilience, while tensile tests assess overall mechanical strength and stretchability.

Equipment Used in Nylon Abrasion Testing

Nylon abrasion testing primarily utilizes specialized equipment such as Taber Abrasers or Martindale abrasion testers to simulate wear and friction on fabric surfaces, providing quantitative data on durability. These devices employ rotating abrasive wheels or standardized rubbing motions to replicate real-world wear conditions, essential for evaluating nylon's resistance to abrasion. Unlike tensile testing machines that measure the force needed to break nylon fibers, abrasion testers focus on surface degradation, using controlled pressure, speed, and cycles to assess fabric longevity.

Methods Employed in Nylon Tensile Testing

Nylon tensile testing primarily employs methods such as the universal testing machine (UTM) to measure tensile strength, elongation, and modulus of elasticity under controlled strain rates. Specimens are typically prepared according to ASTM D638 or ISO 527 standards, which specify dimensions and conditioning to ensure consistent results. This method provides critical data on nylon's mechanical performance compared to abrasion testing, which focuses on surface wear resistance rather than tensile properties.

Interpreting Results: Abrasion Resistance in Nylon

Nylon abrasion testing evaluates the material's durability by measuring weight loss or surface wear after friction exposure, directly indicating its resistance to surface degradation in practical applications. Tensile testing assesses nylon's strength and elongation at break, providing insight into its load-bearing capacity but not surface wear behavior. Interpreting results reveals that high abrasion resistance in nylon correlates with longer service life in abrasive environments, while tensile testing ensures adequate mechanical strength for structural performance.

Tensile Strength Indicators in Nylon Products

Nylon tensile testing measures the maximum stress a nylon product can withstand before breaking, serving as a critical indicator of its mechanical durability and performance under load. Tensile strength indicators such as ultimate tensile strength, yield strength, and elongation at break provide valuable insights into the material's resistance to pulling forces, directly impacting applications in textiles, automotive parts, and industrial components. Comparing nylon abrasion testing, which evaluates surface wear resistance, to tensile testing highlights the importance of tensile strength in ensuring long-term structural integrity and reliability in nylon products exposed to mechanical stresses.

Applications Influenced by Nylon Testing Methods

Nylon abrasion testing evaluates the material's resistance to surface wear, crucial for applications like conveyor belts, automotive parts, and footwear, where durability against friction is essential. Tensile testing measures nylon's strength and elongation properties, influencing its use in load-bearing components such as ropes, textiles, and industrial fasteners. Understanding both test results allows engineers to select nylon grades optimized for performance under mechanical stress and surface wear conditions.

Choosing Between Abrasion and Tensile Testing for Nylon

Nylon abrasion testing evaluates the material's resistance to surface wear and friction, crucial for applications like textiles and automotive interiors where durability against repeated contact is essential. Tensile testing measures nylon's strength and elongation under tension, providing data on load-bearing capacity and flexibility for structural or load-bearing components. Selecting between abrasion and tensile testing depends on the end-use requirements, with abrasion tests suited for surface durability assessment and tensile tests for mechanical strength evaluation.

Nylon Abrasion Testing vs Tensile Testing Infographic

materialdif.com

materialdif.com