Nylon pet fibers exhibit moderate moisture absorption, allowing them to retain some water vapor without becoming saturated, which helps maintain comfort in wearables and upholstery. Compared to natural fibers, nylon offers superior moisture resistance, preventing excessive dampness and drying quickly to reduce the risk of bacterial growth and odor. This balance between moisture absorption and resistance makes nylon pet an ideal choice for durable, moisture-managing textiles.

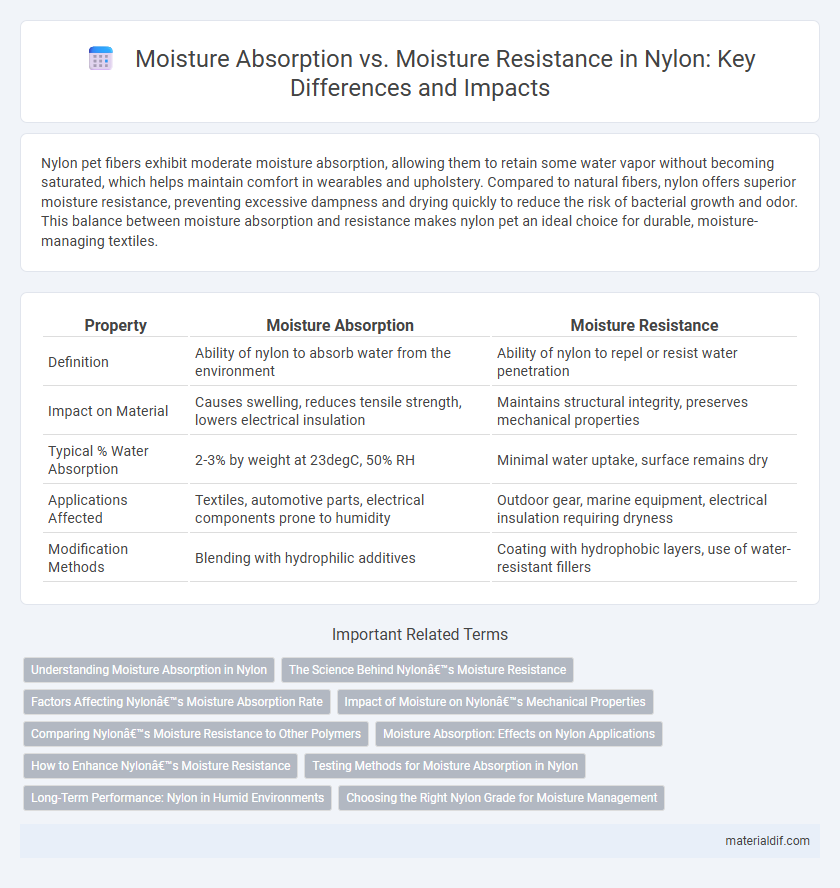

Table of Comparison

| Property | Moisture Absorption | Moisture Resistance |

|---|---|---|

| Definition | Ability of nylon to absorb water from the environment | Ability of nylon to repel or resist water penetration |

| Impact on Material | Causes swelling, reduces tensile strength, lowers electrical insulation | Maintains structural integrity, preserves mechanical properties |

| Typical % Water Absorption | 2-3% by weight at 23degC, 50% RH | Minimal water uptake, surface remains dry |

| Applications Affected | Textiles, automotive parts, electrical components prone to humidity | Outdoor gear, marine equipment, electrical insulation requiring dryness |

| Modification Methods | Blending with hydrophilic additives | Coating with hydrophobic layers, use of water-resistant fillers |

Understanding Moisture Absorption in Nylon

Nylon exhibits significant moisture absorption, typically absorbing up to 4% of its weight in water, which affects its mechanical properties and dimensional stability. Understanding moisture absorption in nylon is crucial for applications where humidity and water exposure are factors, as it influences tensile strength, flexibility, and electrical insulation. Innovations in nylon formulations and coatings aim to enhance moisture resistance, reducing water uptake and improving performance in moist environments.

The Science Behind Nylon’s Moisture Resistance

Nylon's molecular structure features strong hydrogen bonds that reduce the polymer's affinity for water molecules, contributing to its notable moisture resistance. While nylon does absorb some moisture due to its polar amide groups, the extent is limited compared to other synthetic fibers, ensuring durability and dimensional stability in humid conditions. The controlled balance between moisture absorption and resistance makes nylon ideal for applications requiring lightweight, breathable, yet water-repellent materials.

Factors Affecting Nylon’s Moisture Absorption Rate

Nylon's moisture absorption rate is primarily influenced by factors such as temperature, humidity levels, and the specific polymer structure, including crystallinity and molecular weight. Higher ambient humidity and temperature accelerate moisture uptake, while increased crystallinity reduces absorption by limiting available free volume within the polymer matrix. The presence of additives, fiber diameter, and surface treatments also significantly modulate nylon's moisture resistance properties.

Impact of Moisture on Nylon’s Mechanical Properties

Nylon exhibits significant moisture absorption, typically ranging from 2% to 9% by weight, which directly affects its mechanical properties by reducing tensile strength and stiffness while increasing elongation. This moisture uptake causes Nylon to swell and plasticize, leading to decreased dimensional stability and potential degradation under prolonged exposure to humid environments. Moisture resistance treatments or copolymerization techniques can mitigate these effects, enhancing Nylon's durability and performance in applications requiring structural integrity.

Comparing Nylon’s Moisture Resistance to Other Polymers

Nylon exhibits moderate moisture absorption, typically around 2-8%, which can lead to dimensional changes and reduced mechanical properties. Compared to other polymers like polypropylene and polyethylene, which have very low moisture absorption rates below 0.05%, nylon's moisture resistance is significantly lower. However, nylon offers better moisture resistance than hydrophilic polymers such as cellulose-based materials, making it suitable for applications requiring a balance between flexibility and moisture management.

Moisture Absorption: Effects on Nylon Applications

Nylon's moisture absorption significantly impacts its mechanical properties, causing dimensional changes, reduced tensile strength, and decreased stiffness in various applications. High moisture uptake leads to swelling and potential deformation, which affects precision components in automotive and textile industries. Understanding and controlling nylon's moisture absorption is critical for optimizing performance in environments with fluctuating humidity levels.

How to Enhance Nylon’s Moisture Resistance

Enhancing nylon's moisture resistance involves applying hydrophobic coatings such as silicone or fluoropolymer treatments that repel water and reduce absorption. Incorporating additives like carbon black or specific fillers during the polymer extrusion process can also improve moisture resistance by altering nylon's molecular structure. Proper drying and processing techniques further minimize moisture content, thereby enhancing nylon's dimensional stability and mechanical performance in humid environments.

Testing Methods for Moisture Absorption in Nylon

Moisture absorption testing in nylon typically involves gravimetric analysis, where samples are weighed before and after exposure to controlled humidity conditions to determine the percentage of water uptake. Dynamic vapor sorption (DVS) is another precise method, measuring the weight change of nylon as it interacts with varying relative humidity levels, enabling detailed sorption isotherm mapping. These testing methods are crucial for evaluating nylon's hygroscopic behavior, directly impacting its dimensional stability, mechanical properties, and suitability for various industrial applications.

Long-Term Performance: Nylon in Humid Environments

Nylon exhibits notable moisture absorption properties, typically absorbing up to 4% of its weight in water, which can lead to dimensional changes and reduced mechanical strength over time. Despite this, its inherent moisture resistance enables it to retain adequate tensile strength and flexibility, making it suitable for long-term use in humid environments where consistent performance is required. Advances in nylon formulations, such as the incorporation of hydrophobic additives, further enhance its durability and stability under prolonged exposure to moisture.

Choosing the Right Nylon Grade for Moisture Management

Nylon grades vary significantly in moisture absorption, with standard Nylon 6 absorbing up to 8% of its weight in water, affecting dimensional stability and mechanical properties. Moisture-resistant nylons like Nylon 6/6 or those modified with hydrophobic additives offer superior resistance, maintaining strength and flexibility in damp environments. Selecting the right nylon grade depends on the application's exposure to humidity, balancing moisture absorption levels with performance requirements to ensure durability and functionality.

Moisture absorption vs Moisture resistance Infographic

materialdif.com

materialdif.com