Aromatic nylon exhibits superior thermal stability and mechanical strength, making it ideal for high-performance applications such as automotive parts and industrial components. In contrast, aliphatic nylon offers excellent chemical resistance and flexibility, which suits uses in textiles, packaging, and consumer goods. Choosing between aromatic and aliphatic nylon depends on the specific requirements for durability, chemical exposure, and environmental conditions.

Table of Comparison

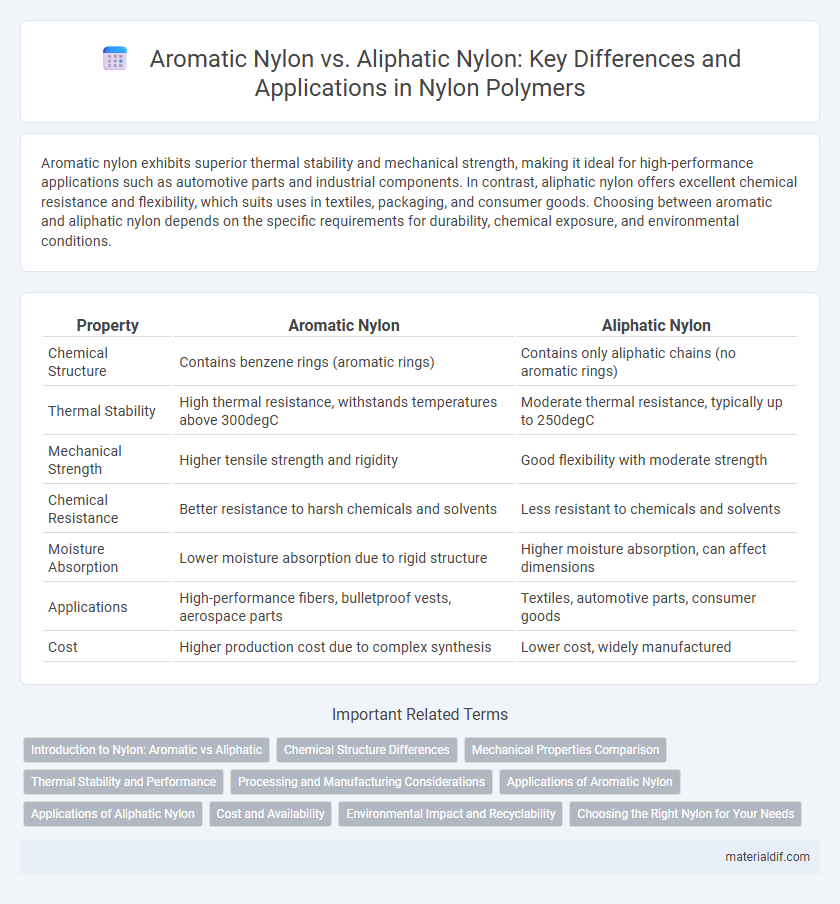

| Property | Aromatic Nylon | Aliphatic Nylon |

|---|---|---|

| Chemical Structure | Contains benzene rings (aromatic rings) | Contains only aliphatic chains (no aromatic rings) |

| Thermal Stability | High thermal resistance, withstands temperatures above 300degC | Moderate thermal resistance, typically up to 250degC |

| Mechanical Strength | Higher tensile strength and rigidity | Good flexibility with moderate strength |

| Chemical Resistance | Better resistance to harsh chemicals and solvents | Less resistant to chemicals and solvents |

| Moisture Absorption | Lower moisture absorption due to rigid structure | Higher moisture absorption, can affect dimensions |

| Applications | High-performance fibers, bulletproof vests, aerospace parts | Textiles, automotive parts, consumer goods |

| Cost | Higher production cost due to complex synthesis | Lower cost, widely manufactured |

Introduction to Nylon: Aromatic vs Aliphatic

Aromatic nylons, such as Kevlar and Nomex, are characterized by rigid, benzene-ring structures that provide superior thermal stability, mechanical strength, and chemical resistance compared to aliphatic nylons like Nylon 6 and Nylon 66, which contain linear or slightly branched chains. Aliphatic nylons offer excellent flexibility, moisture absorption, and ease of processing, making them suitable for fibers, textiles, and packaging. The fundamental difference lies in the aromatic rings enhancing performance attributes in demanding applications, whereas aliphatic nylons emphasize versatility and cost-effectiveness.

Chemical Structure Differences

Aromatic nylon features rigid, benzene ring-containing polymer chains, enhancing thermal stability and mechanical strength. Aliphatic nylon consists of flexible, straight carbon chains without aromatic rings, resulting in higher elasticity and ease of dyeing. The presence of aromatic rings in aromatic nylon increases crystallinity and chemical resistance compared to the more amorphous and moisture-absorbent aliphatic nylon structure.

Mechanical Properties Comparison

Aromatic nylons, such as Nylon 6,6, exhibit higher tensile strength and greater thermal stability compared to aliphatic nylons like Nylon 6, due to their rigid molecular backbone structure. The increased crystallinity and hydrogen bonding in aromatic nylons result in superior abrasion resistance and dimensional stability under mechanical stress. Conversely, aliphatic nylons offer better impact resistance and flexibility but generally show lower modulus and strength values in mechanical performance tests.

Thermal Stability and Performance

Aromatic nylon exhibits superior thermal stability compared to aliphatic nylon due to its rigid benzene ring structure, which enhances heat resistance and dimensional stability at elevated temperatures. This results in better performance in high-temperature applications such as automotive components and industrial machinery parts. Conversely, aliphatic nylons offer greater flexibility and impact resistance but have lower melting points and degrade faster under thermal stress.

Processing and Manufacturing Considerations

Aromatic nylon, characterized by its rigid molecular structure, requires higher processing temperatures typically above 280degC and specialized equipment to maintain its thermal stability during manufacturing. Aliphatic nylon, being more flexible with a lower melting point generally between 220degC and 270degC, allows for easier extrusion and injection molding processes, reducing energy consumption and cycle times. Selecting the appropriate type depends on the desired mechanical properties and end-use applications, with aromatic nylon favored for high-performance fibers and aliphatic nylon commonly used in general-purpose textiles and engineering plastics.

Applications of Aromatic Nylon

Aromatic nylon, derived from aromatic diamines and dicarboxylic acids, is widely used in high-performance applications due to its superior thermal stability, chemical resistance, and mechanical strength. It is commonly utilized in automotive components, electrical insulation, and industrial machinery where durability under extreme conditions is essential. In contrast to aliphatic nylons, aromatic nylons provide enhanced dimensional stability and flame retardancy, making them ideal for demanding engineering applications.

Applications of Aliphatic Nylon

Aliphatic nylon, known for its excellent chemical resistance, high tensile strength, and flexibility, finds extensive applications in textiles, automotive parts, and industrial components. Its superior resistance to abrasion and UV exposure makes it ideal for manufacturing durable garments, ropes, and tire cords. Aliphatic nylon is also favored in electrical insulation and consumer goods due to its notable thermal stability and moisture absorption properties.

Cost and Availability

Aromatic nylon, such as Nylon 6,6, offers high strength and thermal resistance but typically comes at a higher cost due to complex synthesis and limited raw material availability. Aliphatic nylons like Nylon 6 are more cost-effective and widely available, benefiting from simpler production processes and abundant feedstocks. The choice between aromatic and aliphatic nylon often depends on balancing performance demands with budget and supply chain reliability.

Environmental Impact and Recyclability

Aromatic nylon, derived from benzene ring-containing monomers, exhibits higher chemical resistance and strength but poses greater environmental challenges due to its complex polymer structure, making recycling processes more energy-intensive and less efficient. Aliphatic nylon, synthesized from straight-chain monomers, offers easier recyclability and lower environmental impact because its simpler molecular structure allows for more straightforward depolymerization and reuse. Both types contribute to plastic waste, but aliphatic nylons are favored in sustainable applications due to better biodegradability and lower greenhouse gas emissions during recycling.

Choosing the Right Nylon for Your Needs

Aromatic nylon, known for its superior thermal stability and mechanical strength, is ideal for high-performance applications like automotive parts and industrial machinery. Aliphatic nylon offers excellent chemical resistance and flexibility, making it suitable for consumer goods and textiles. Selecting the right nylon depends on balancing factors such as temperature exposure, strength requirements, and chemical resistance to ensure optimal material performance.

Aromatic Nylon vs Aliphatic Nylon Infographic

materialdif.com

materialdif.com