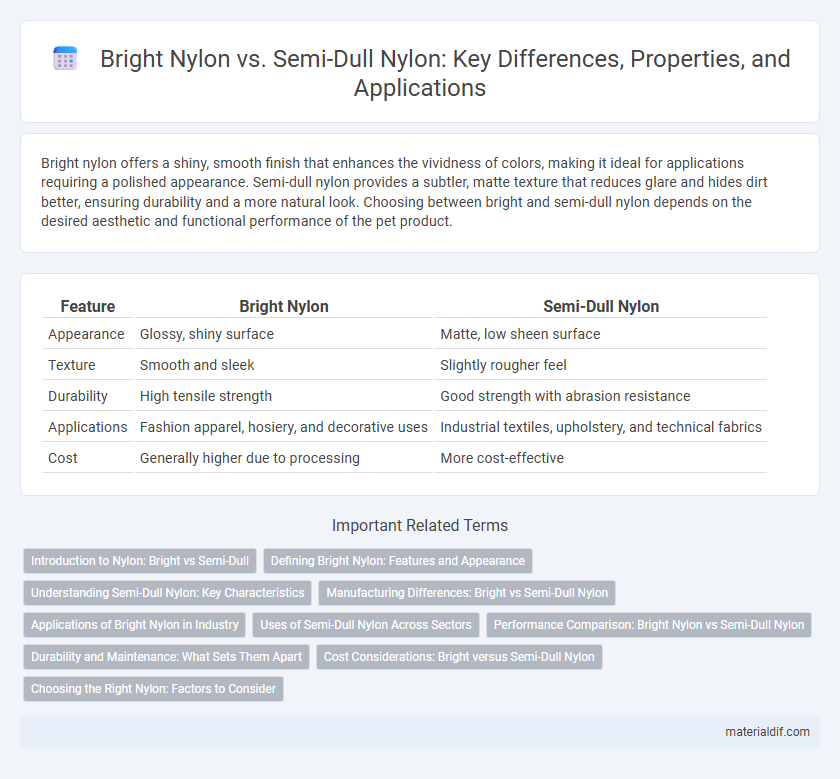

Bright nylon offers a shiny, smooth finish that enhances the vividness of colors, making it ideal for applications requiring a polished appearance. Semi-dull nylon provides a subtler, matte texture that reduces glare and hides dirt better, ensuring durability and a more natural look. Choosing between bright and semi-dull nylon depends on the desired aesthetic and functional performance of the pet product.

Table of Comparison

| Feature | Bright Nylon | Semi-Dull Nylon |

|---|---|---|

| Appearance | Glossy, shiny surface | Matte, low sheen surface |

| Texture | Smooth and sleek | Slightly rougher feel |

| Durability | High tensile strength | Good strength with abrasion resistance |

| Applications | Fashion apparel, hosiery, and decorative uses | Industrial textiles, upholstery, and technical fabrics |

| Cost | Generally higher due to processing | More cost-effective |

Introduction to Nylon: Bright vs Semi-Dull

Bright nylon features a smooth, shiny surface achieved through a high-gloss finish, enhancing its visual appeal and making it ideal for applications requiring a polished look. Semi-dull nylon, by contrast, has a matte, less reflective surface created by adding delustrants during production, offering reduced glare and improved dye uptake for more vibrant colors. Understanding the differences between bright and semi-dull nylon helps manufacturers select the appropriate type based on aesthetic and functional requirements in textiles and industrial uses.

Defining Bright Nylon: Features and Appearance

Bright nylon features a smooth, glossy surface that reflects light, creating a shiny and vibrant appearance ideal for high-visibility applications. Its manufacturing process includes precise polymer crystallization, resulting in enhanced strength and durability compared to semi-dull nylon. The distinct luster and sleek texture of bright nylon make it a preferred choice in textiles, apparel, and industrial uses where aesthetic appeal and robust performance are critical.

Understanding Semi-Dull Nylon: Key Characteristics

Semi-dull nylon features a matte finish created by adding titanium dioxide during production, reducing its shine compared to bright nylon. This finish enhances dye absorption, resulting in deeper, richer colors and improved colorfastness. Semi-dull nylon is preferred in applications requiring less glare and a softer, more natural appearance.

Manufacturing Differences: Bright vs Semi-Dull Nylon

Bright nylon is produced using a process that retains the polymer's natural luster, resulting in a smooth, shiny surface ideal for applications requiring high sheen and clarity. Semi-dull nylon undergoes a delustering treatment where titanium dioxide or other delustrants are added during manufacturing, reducing light reflection and creating a matte appearance that enhances colorfastness and hides imperfections. The primary manufacturing difference lies in the addition of these delustering agents in semi-dull nylon, which modifies the fiber's refractive index and surface texture, contrasting with the untreated, glossy bright nylon fibers.

Applications of Bright Nylon in Industry

Bright Nylon is widely used in textile manufacturing for producing high-strength, smooth, and glossy synthetic fibers ideal for hosiery, lingerie, and parachutes. Its enhanced luster and uniform surface make it preferred in industrial applications requiring aesthetic appeal and durability, such as automotive upholstery and sportswear. Bright Nylon also serves critical roles in industrial filaments for tire cords and ropes where tensile strength and abrasion resistance are paramount.

Uses of Semi-Dull Nylon Across Sectors

Semi-dull nylon is widely utilized in the textile and apparel industry for manufacturing durable fabrics with a matte finish that reduces glare and enhances color depth. Its resistance to wear and moisture absorption makes it ideal for automotive components, industrial filters, and tire cords, providing longevity and performance. Additionally, semi-dull nylon's versatility extends to consumer goods such as backpacks, ropes, and sportswear, where strength and subdued aesthetics are essential.

Performance Comparison: Bright Nylon vs Semi-Dull Nylon

Bright Nylon offers superior tensile strength and smoother surface finish compared to Semi-Dull Nylon, making it ideal for high-performance applications requiring durability and aesthetic appeal. Semi-Dull Nylon exhibits better dye uptake and reduced glare, enhancing its suitability for textiles and automotive parts where colorfastness and reduced reflectivity are prioritized. Performance metrics reveal Bright Nylon excels in abrasion resistance, while Semi-Dull Nylon provides improved processing efficiency and cost-effectiveness.

Durability and Maintenance: What Sets Them Apart

Bright nylon features a smooth, glossy finish that enhances durability by resisting dirt and stains, making maintenance easier compared to semi-dull nylon. Semi-dull nylon, with its matte texture, tends to show less surface wear and can better hide minor abrasions, but may require more frequent cleaning to maintain appearance. The choice between bright and semi-dull nylon ultimately depends on the specific durability needs and maintenance preferences for the intended application.

Cost Considerations: Bright versus Semi-Dull Nylon

Bright nylon typically costs more than semi-dull nylon due to its higher quality finish and enhanced aesthetic appeal, which require additional processing steps. Semi-dull nylon offers a more budget-friendly option while maintaining adequate durability and performance for many industrial applications. Manufacturers often choose semi-dull nylon to balance cost efficiency with acceptable visual and functional properties.

Choosing the Right Nylon: Factors to Consider

Choosing the right nylon between bright nylon and semi-dull nylon depends on factors such as the desired appearance, texture, and end-use application. Bright nylon offers a shiny, smooth finish ideal for high-visibility products and fashion items, while semi-dull nylon provides a matte, less reflective surface suited for industrial or technical uses. Considerations like abrasion resistance, dyeability, and weather durability also influence the selection to ensure optimal performance and aesthetic appeal.

Bright Nylon vs Semi-Dull Nylon Infographic

materialdif.com

materialdif.com