Polyamide and nylon are closely related synthetic polymers commonly used in pet products for their durability and strength. Nylon is a type of polyamide known for its excellent resistance to abrasion and moisture, making it ideal for pet collars, leashes, and toys. Choosing nylon, a specific polyamide variant, ensures better elasticity and longevity in pet accessories compared to general polyamide materials.

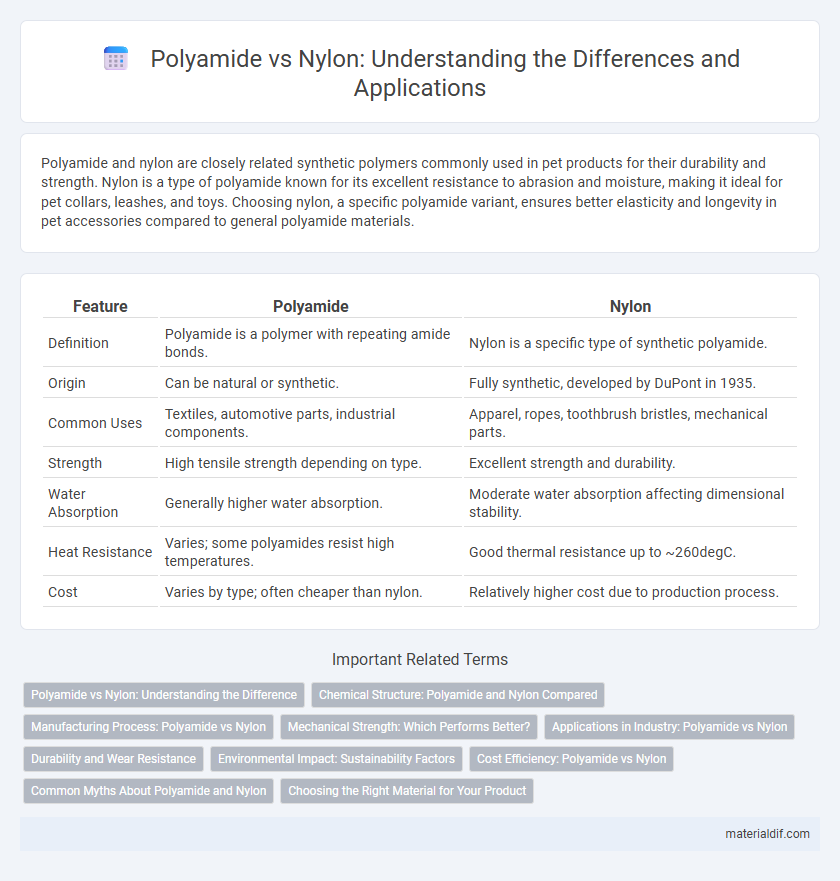

Table of Comparison

| Feature | Polyamide | Nylon |

|---|---|---|

| Definition | Polyamide is a polymer with repeating amide bonds. | Nylon is a specific type of synthetic polyamide. |

| Origin | Can be natural or synthetic. | Fully synthetic, developed by DuPont in 1935. |

| Common Uses | Textiles, automotive parts, industrial components. | Apparel, ropes, toothbrush bristles, mechanical parts. |

| Strength | High tensile strength depending on type. | Excellent strength and durability. |

| Water Absorption | Generally higher water absorption. | Moderate water absorption affecting dimensional stability. |

| Heat Resistance | Varies; some polyamides resist high temperatures. | Good thermal resistance up to ~260degC. |

| Cost | Varies by type; often cheaper than nylon. | Relatively higher cost due to production process. |

Polyamide vs Nylon: Understanding the Difference

Polyamide and nylon are often used interchangeably, but polyamide refers to a broader class of polymers containing repeating amide linkages, while nylon is a specific type of polyamide. Nylon typically features synthetic polymers like Nylon 6 and Nylon 6,6, distinguished by their molecular structure and manufacturing processes. Understanding the difference involves recognizing nylon as a subset of polyamides, commonly applied in textiles, automotive parts, and industrial applications due to its strength and durability.

Chemical Structure: Polyamide and Nylon Compared

Polyamide and Nylon share a fundamental chemical structure characterized by repeating amide linkages (-CONH-) formed through condensation polymerization of diamines and dicarboxylic acids. Nylon, a specific subset of synthetic polyamides, typically features uniform monomer units such as hexamethylene diamine and adipic acid in Nylon 6,6 or caprolactam in Nylon 6, resulting in consistent chain regularity and crystallinity. The precise arrangement of molecular chains in Nylon imparts superior mechanical strength, thermal stability, and chemical resistance compared to more diverse polyamide classifications.

Manufacturing Process: Polyamide vs Nylon

Polyamide and Nylon both originate from synthetic polymers primarily produced through condensation polymerization, but Nylon typically refers to specific polyamide types such as Nylon 6 or Nylon 6,6. The manufacturing process for Nylon involves the polymerization of diamines and dicarboxylic acids or caprolactam, resulting in high molecular weight fibers known for strength and elasticity. Polyamide production encompasses a broader range of polyamide types with varied monomers and polymerization methods, influencing their thermal properties and applications in textiles, automotive, and industrial sectors.

Mechanical Strength: Which Performs Better?

Polyamide and Nylon are often used interchangeably but differ slightly in mechanical strength due to their molecular structures. Nylon, a specific type of polyamide, generally exhibits superior tensile strength and impact resistance, making it ideal for applications requiring durability and flexibility. Mechanical performance varies by Nylon types, with Nylon 6 and Nylon 6,6 offering higher strength compared to some generic polyamides.

Applications in Industry: Polyamide vs Nylon

Polyamide and Nylon are often used interchangeably in industry, with Nylon being a type of synthetic polyamide known for its superior strength and elasticity. Polyamide materials find extensive applications in automotive components, textiles, and industrial machinery due to their chemical resistance and durability. Nylon specifically dominates in manufacturing gears, bearings, and high-performance fabrics, benefiting sectors like aerospace, sports equipment, and electronics.

Durability and Wear Resistance

Polyamide and Nylon are both synthetic polymers known for their high durability and excellent wear resistance, making them ideal for abrasive environments. Nylon, a specific type of polyamide, typically offers superior tensile strength and elasticity, enhancing its ability to withstand repetitive stress and impact without significant degradation. Polyamide materials generally exhibit strong chemical resistance and abrasion tolerance, but Nylon's molecular structure provides an edge in sustained mechanical performance and longevity in industrial applications.

Environmental Impact: Sustainability Factors

Polyamide and nylon share similar environmental impacts, as both are synthetic polymers derived from petrochemicals, contributing to non-renewable resource depletion. Nylon's production releases significant greenhouse gases and generates waste difficult to biodegrade, raising concerns about pollution and landfill accumulation. Advances in recycling technologies and the development of bio-based polyamides promote sustainability by reducing carbon footprints and reliance on fossil fuels.

Cost Efficiency: Polyamide vs Nylon

Polyamide and nylon are often used interchangeably but differ slightly in manufacturing costs and applications. Nylon, a specific type of polyamide, generally offers better cost efficiency due to its widespread production and availability, reducing material expenses for industries. Polyamide variants may incur higher costs depending on their chemical composition and performance characteristics, impacting budget considerations in textile and engineering sectors.

Common Myths About Polyamide and Nylon

Polyamide and nylon are often mistakenly treated as different materials, but nylon is actually a specific type of polyamide, distinguished by the presence of amide linkages in its molecular structure. Common myths suggest polyamide fabrics are less durable or uncomfortable, when in fact nylon offers high strength, elasticity, and moisture-wicking properties that make it ideal for textiles and industrial applications. Misconceptions also arise about environmental impact; while nylon production involves synthetic polymers, advancements in recycling and bio-based polyamides are helping reduce its ecological footprint significantly.

Choosing the Right Material for Your Product

Polyamide and nylon are often used interchangeably, but subtle differences impact product performance and application. Polyamide refers to a broader category of synthetic polymers, while nylon specifically denotes a family of polyamides with high strength, flexibility, and resistance to abrasion. Selecting the right material depends on factors such as durability requirements, environmental exposure, and cost-effectiveness to ensure optimal product functionality.

Polyamide vs Nylon Infographic

materialdif.com

materialdif.com