Heat stabilized nylon offers enhanced resistance to thermal degradation, making it ideal for applications involving prolonged exposure to high temperatures. UV stabilized nylon is specifically treated to withstand damage from ultraviolet light, preventing brittleness and color fading in outdoor environments. Selecting between the two depends on whether heat resistance or UV protection is the priority for the intended use.

Table of Comparison

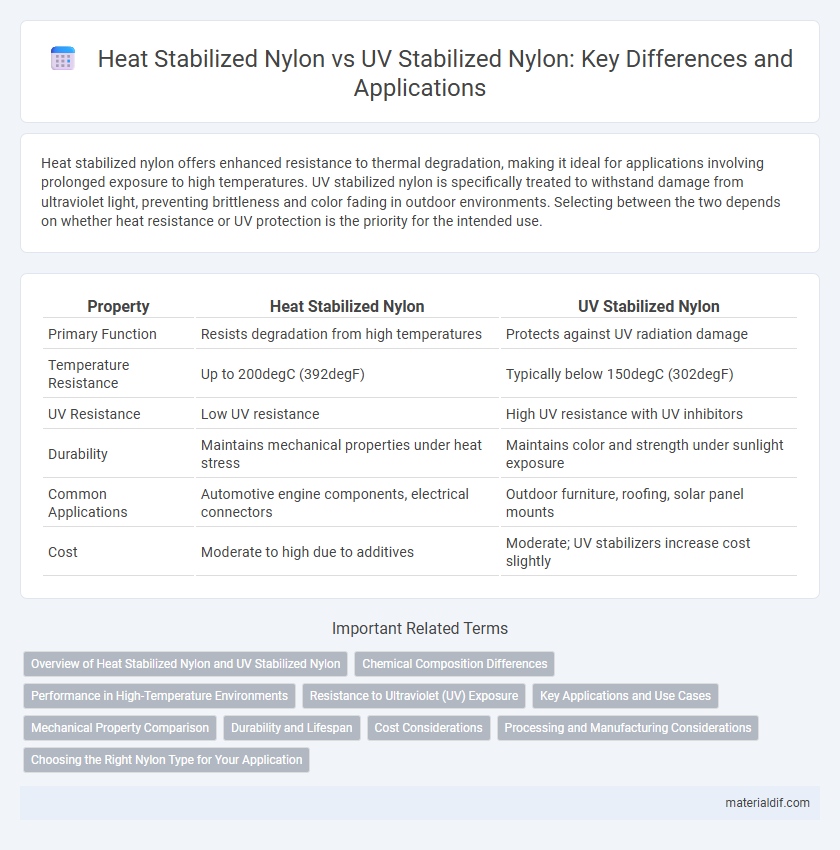

| Property | Heat Stabilized Nylon | UV Stabilized Nylon |

|---|---|---|

| Primary Function | Resists degradation from high temperatures | Protects against UV radiation damage |

| Temperature Resistance | Up to 200degC (392degF) | Typically below 150degC (302degF) |

| UV Resistance | Low UV resistance | High UV resistance with UV inhibitors |

| Durability | Maintains mechanical properties under heat stress | Maintains color and strength under sunlight exposure |

| Common Applications | Automotive engine components, electrical connectors | Outdoor furniture, roofing, solar panel mounts |

| Cost | Moderate to high due to additives | Moderate; UV stabilizers increase cost slightly |

Overview of Heat Stabilized Nylon and UV Stabilized Nylon

Heat stabilized nylon is engineered to withstand high-temperature environments by incorporating heat-resistant additives that prevent thermal degradation and maintain mechanical properties at elevated temperatures. UV stabilized nylon contains specific ultraviolet light absorbers and hindered amine light stabilizers (HALS) to protect against polymer chain breakdown caused by prolonged exposure to sunlight, thereby enhancing weatherability and color retention. Both types improve nylon's durability but target distinct environmental stressors: heat stabilized nylon excels in thermal resistance while UV stabilized nylon offers superior resistance to photodegradation.

Chemical Composition Differences

Heat stabilized nylon contains additives such as antioxidants and thermal stabilizers that enhance its resistance to high temperatures by preventing polymer degradation and chain scission during thermal exposure. UV stabilized nylon incorporates UV absorbers and hindered amine light stabilizers (HALS) that protect the polymer matrix from photodegradation by absorbing harmful ultraviolet radiation and neutralizing free radicals. The key chemical difference lies in the specific stabilizing agents tailored to thermal versus photochemical protection mechanisms, impacting nylon's durability in heat-intensive versus sun-exposed applications.

Performance in High-Temperature Environments

Heat stabilized nylon exhibits superior performance in high-temperature environments by maintaining structural integrity and mechanical properties at elevated temperatures up to 150degC. UV stabilized nylon, while offering excellent resistance to ultraviolet radiation and weathering, does not significantly enhance thermal stability and may degrade faster under prolonged heat exposure. For applications demanding robust heat resistance, heat stabilized nylon is the preferred choice due to its enhanced thermal aging resistance and reduced dimensional changes.

Resistance to Ultraviolet (UV) Exposure

Heat stabilized nylon exhibits moderate resistance to ultraviolet (UV) exposure by maintaining its mechanical properties under elevated temperatures, but it may degrade faster when exposed to prolonged UV radiation. UV stabilized nylon incorporates specific additives that significantly enhance resistance to UV degradation, preventing discoloration, cracking, and loss of tensile strength under direct sunlight. For outdoor applications requiring long-term UV exposure durability, UV stabilized nylon offers superior performance compared to heat stabilized variants.

Key Applications and Use Cases

Heat stabilized nylon is ideal for automotive engine components and electrical connectors, where high temperature resistance prevents deformation and maintains mechanical integrity. UV stabilized nylon is preferred in outdoor applications such as construction materials, sporting goods, and outdoor furniture, providing resistance against UV radiation to avoid discoloration and brittleness. Both variations enhance nylon's durability but cater to distinct environmental challenges: thermal exposure versus prolonged sun exposure.

Mechanical Property Comparison

Heat stabilized nylon exhibits enhanced thermal resistance, maintaining tensile strength and dimensional stability under elevated temperatures, making it ideal for applications involving prolonged heat exposure. UV stabilized nylon offers superior resistance to ultraviolet radiation, preventing surface degradation and preserving impact strength, which is critical for outdoor and sun-exposed environments. Mechanical properties such as elongation at break and modulus of elasticity remain more consistent in heat stabilized nylon under thermal stress, while UV stabilized nylon excels in retaining flexibility and toughness after extended UV exposure.

Durability and Lifespan

Heat stabilized nylon offers enhanced resistance to thermal degradation, maintaining mechanical strength and dimensional stability at elevated temperatures, which significantly extends its lifespan in high-heat applications. UV stabilized nylon incorporates additives that absorb and dissipate ultraviolet radiation, preventing polymer chain breakdown and surface cracking, thereby improving durability under prolonged sun exposure. Selecting between heat stabilized and UV stabilized nylon depends on the primary environmental stressors; thermal conditions favor heat stabilized grades, while outdoor applications with intense sunlight benefit more from UV stabilized formulations.

Cost Considerations

Heat stabilized nylon typically incurs higher production costs due to the use of specialized additives that enhance thermal resistance, making it ideal for applications exposed to elevated temperatures. UV stabilized nylon contains ultraviolet inhibitors that prevent degradation from sunlight exposure, often resulting in moderately increased material expenses compared to standard nylon. Budget decisions must weigh the environmental conditions and performance requirements, as heat stabilization is more costly but essential for heat-intensive environments, whereas UV stabilization offers cost-effective protection in outdoor or sun-exposed applications.

Processing and Manufacturing Considerations

Heat stabilized nylon requires controlled processing temperatures between 260degC and 280degC to prevent thermal degradation and maintain mechanical properties, while UV stabilized nylon incorporates additives during compounding to enhance resistance against photodegradation without significantly altering melt viscosity. Manufacturing heat stabilized nylon often demands inert atmospheres or vacuum drying to reduce moisture content, ensuring dimensional stability and reducing hydrolytic breakdown. UV stabilized nylon production involves careful dispersion of UV absorbers or hindered amine light stabilizers (HALS) within the polymer matrix to optimize long-term outdoor performance without compromising processability.

Choosing the Right Nylon Type for Your Application

Heat stabilized nylon offers enhanced thermal resistance, making it ideal for applications involving prolonged exposure to high temperatures such as automotive engine components and electrical connectors. UV stabilized nylon contains additives that protect against degradation from ultraviolet light, ensuring durability in outdoor environments like outdoor furniture and marine hardware. Selecting the right nylon depends on the specific environmental conditions, with heat stabilization prioritized for thermal load and UV stabilization for sun exposure resilience.

Heat Stabilized Nylon vs UV Stabilized Nylon Infographic

materialdif.com

materialdif.com