Nylon resin and nylon polymer are often used interchangeably, but nylon resin refers specifically to the processed form of nylon polymer ready for molding into products like pet toys. Nylon polymer is the raw chemical substance composed of repeating units that provide durability, flexibility, and resistance to wear. Understanding the distinction helps manufacturers optimize material properties for creating robust, safe, and long-lasting nylon pet products.

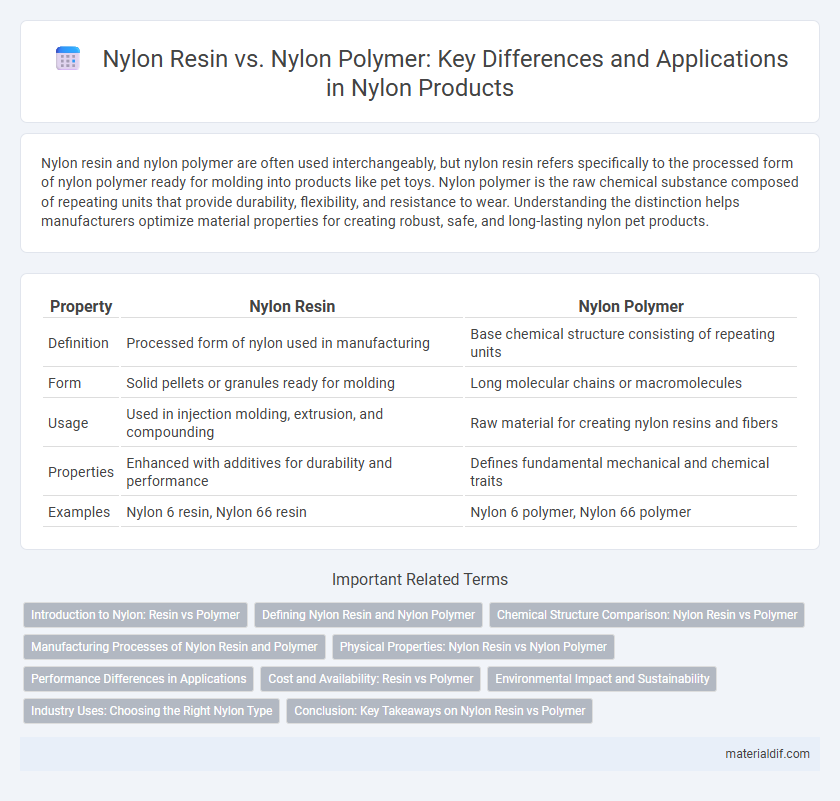

Table of Comparison

| Property | Nylon Resin | Nylon Polymer |

|---|---|---|

| Definition | Processed form of nylon used in manufacturing | Base chemical structure consisting of repeating units |

| Form | Solid pellets or granules ready for molding | Long molecular chains or macromolecules |

| Usage | Used in injection molding, extrusion, and compounding | Raw material for creating nylon resins and fibers |

| Properties | Enhanced with additives for durability and performance | Defines fundamental mechanical and chemical traits |

| Examples | Nylon 6 resin, Nylon 66 resin | Nylon 6 polymer, Nylon 66 polymer |

Introduction to Nylon: Resin vs Polymer

Nylon resin refers to the raw thermoplastic material used in manufacturing processes, typically delivered in pellet or powder form, which can be melted and molded into various products. Nylon polymer is the long-chain synthetic polyamide created through polymerization of monomers like caprolactam, giving it strength and flexibility at the molecular level. Understanding the distinction between nylon resin as the processing material and nylon polymer as the molecular structure is essential for optimizing applications in textiles, automotive parts, and industrial components.

Defining Nylon Resin and Nylon Polymer

Nylon resin refers to the raw, pelletized form of nylon used as a feedstock in manufacturing processes such as injection molding and extrusion. Nylon polymer is the long-chain synthetic polymer composed of repeating amide groups, resulting from the polymerization of monomers like caprolactam or hexamethylene diamine and adipic acid. While nylon polymer defines the chemical structure and properties, nylon resin represents the practical, processed material ready for fabrication into final products.

Chemical Structure Comparison: Nylon Resin vs Polymer

Nylon resin refers to the processed form of nylon polymer, which is primarily composed of polyamides synthesized through condensation polymerization of diamines and dicarboxylic acids. The chemical structure of nylon polymer consists of repeating amide linkages (-CONH-) within a linear or semi-crystalline chain, contributing to its strength and flexibility. In comparison, nylon resin embodies these polymer chains processed into solid granules or pellets, ready for melting and molding in manufacturing applications.

Manufacturing Processes of Nylon Resin and Polymer

Nylon resin and nylon polymer differ primarily in their manufacturing processes, with nylon resin produced through condensation polymerization of diamines and dicarboxylic acids, creating solid granules suitable for molding applications. Nylon polymer refers to the molecular chains formed during this polymerization, which can be further processed into fibers, films, or resins depending on cooling and extrusion techniques. The precise control of temperature and reaction time during manufacturing ensures the desired molecular weight and mechanical properties of the final nylon material.

Physical Properties: Nylon Resin vs Nylon Polymer

Nylon resin refers to the raw, unprocessed form of nylon, characterized by its solid pellets or granules, while nylon polymer denotes the molecular structure formed by long chains of repeating units that give nylon its fundamental properties. Nylon resins exhibit physical properties such as high melting points around 220-270degC and excellent abrasion resistance, making them ideal for molding applications. In contrast, the nylon polymer's intrinsic properties, including tensile strength of approximately 70 MPa and flexibility, define the mechanical performance and durability of finished nylon products.

Performance Differences in Applications

Nylon resin, a processed form of nylon polymer, offers enhanced consistency and ease of molding compared to raw nylon polymer, leading to superior mechanical properties in finished products. Applications requiring high impact resistance, tensile strength, and thermal stability benefit significantly from nylon resin's uniform molecular structure and controlled additives. In contrast, nylon polymer in its raw state may exhibit variable performance due to inconsistent polymer chain lengths and fewer stabilizers, making nylon resin the preferred choice for precision engineering and high-performance components.

Cost and Availability: Resin vs Polymer

Nylon resin typically costs less than nylon polymer due to its more refined processing and widespread industrial demand, making it a cost-efficient choice for manufacturing. Nylon polymer, being a rawer form, often requires additional processing steps, increasing its overall expense and reducing immediate availability. Suppliers generally stock nylon resin in larger quantities, ensuring a more reliable supply chain compared to bulk nylon polymer.

Environmental Impact and Sustainability

Nylon resin, a processed form of nylon polymer, typically involves more energy-intensive manufacturing steps, increasing its environmental footprint compared to raw nylon polymer. Nylon polymers, being the fundamental molecular chains, offer more opportunities for recycling and bio-based sourcing, enhancing sustainability potential. Lifecycle assessments show that using recycled nylon polymers significantly reduces greenhouse gas emissions and waste generation relative to virgin nylon resin production.

Industry Uses: Choosing the Right Nylon Type

Nylon resin refers to the raw, processed form of nylon used in molding and extrusion, while nylon polymer denotes the molecular structure and chemical composition of the material. Industry applications prioritize nylon resin for manufacturing durable components in automotive parts, electrical housings, and consumer goods due to its ease of processing, whereas nylon polymer characteristics influence material selection in high-performance textiles and engineering plastics. Understanding the differences ensures optimal use of nylon types tailored for specific industrial requirements, balancing strength, flexibility, and chemical resistance.

Conclusion: Key Takeaways on Nylon Resin vs Polymer

Nylon resin refers to the processed, solid form of nylon used for manufacturing durable plastic components, while nylon polymer denotes the raw, long-chain polymer molecules that make up the material. Understanding the distinction is crucial for applications in engineering and manufacturing where mechanical properties and processability matter. Nylon resin's enhanced consistency and moldability make it ideal for injection molding, whereas nylon polymer forms the base chemical structure that defines the material's fundamental strength and flexibility.

Nylon Resin vs Nylon Polymer Infographic

materialdif.com

materialdif.com