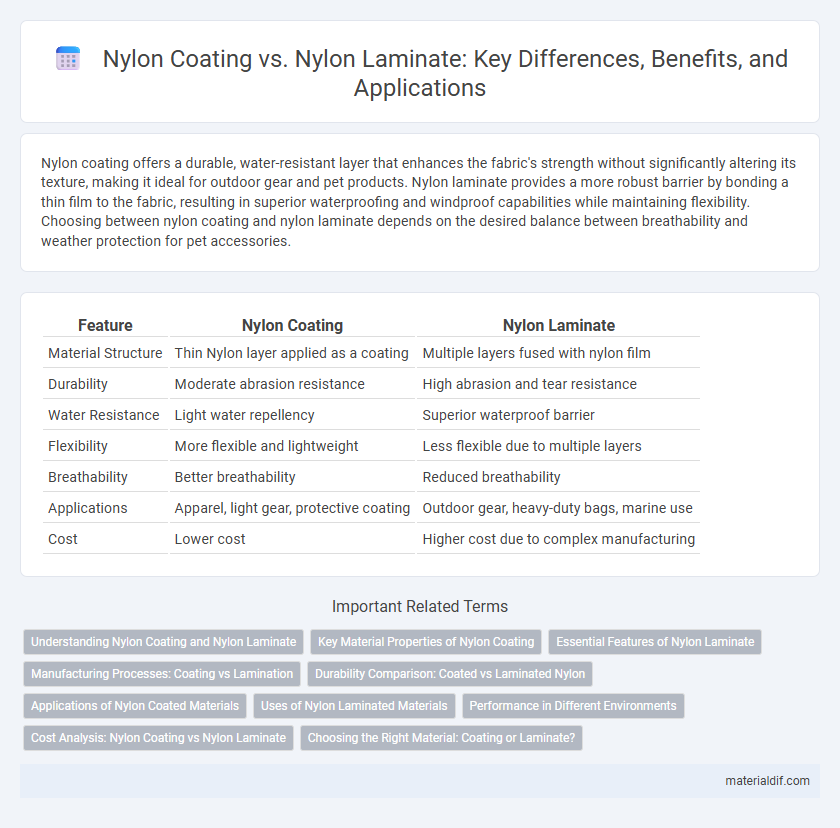

Nylon coating offers a durable, water-resistant layer that enhances the fabric's strength without significantly altering its texture, making it ideal for outdoor gear and pet products. Nylon laminate provides a more robust barrier by bonding a thin film to the fabric, resulting in superior waterproofing and windproof capabilities while maintaining flexibility. Choosing between nylon coating and nylon laminate depends on the desired balance between breathability and weather protection for pet accessories.

Table of Comparison

| Feature | Nylon Coating | Nylon Laminate |

|---|---|---|

| Material Structure | Thin Nylon layer applied as a coating | Multiple layers fused with nylon film |

| Durability | Moderate abrasion resistance | High abrasion and tear resistance |

| Water Resistance | Light water repellency | Superior waterproof barrier |

| Flexibility | More flexible and lightweight | Less flexible due to multiple layers |

| Breathability | Better breathability | Reduced breathability |

| Applications | Apparel, light gear, protective coating | Outdoor gear, heavy-duty bags, marine use |

| Cost | Lower cost | Higher cost due to complex manufacturing |

Understanding Nylon Coating and Nylon Laminate

Nylon coating involves applying a thin layer of nylon polymer directly onto fabric to enhance water resistance, durability, and abrasion resistance without significantly increasing weight. Nylon laminate consists of bonding a nylon film layer to the substrate, providing superior waterproofing, wind resistance, and a smoother finish, often used in outdoor gear and technical apparel. Understanding these differences helps in selecting the right material based on performance needs such as breathability, flexibility, and protection.

Key Material Properties of Nylon Coating

Nylon coating provides enhanced abrasion resistance, flexibility, and water repellency, making it ideal for protective gear and outdoor fabrics. Its strong adhesion to substrates ensures durability and resistance to wear and tear, while maintaining breathability and lightweight characteristics. This key material property combination distinguishes nylon coating from nylon laminate, which typically offers a thicker, less flexible barrier for waterproof applications.

Essential Features of Nylon Laminate

Nylon laminate combines a nylon fabric base with a polymer film layer, resulting in enhanced waterproofing, durability, and chemical resistance compared to standard nylon coatings. This multi-layer construction ensures superior abrasion resistance and improved barrier properties, making it ideal for outdoor gear and protective applications. Its flexibility and lightweight nature maintain the garment's comfort while providing robust protection against environmental elements.

Manufacturing Processes: Coating vs Lamination

Nylon coating involves applying a liquid polymer directly onto the fabric surface, creating a protective layer through processes such as dipping, knife coating, or spraying, which bonds tightly upon curing. Nylon lamination, by contrast, mechanically or adhesively fuses a pre-formed nylon film onto the fabric, often using heat and pressure to ensure durability and flexibility. Coating provides enhanced water resistance and texture customization, while lamination offers superior film uniformity and added strength due to the continuous nylon layer.

Durability Comparison: Coated vs Laminated Nylon

Nylon coating enhances fabric durability by adding a protective polymer layer that resists abrasion, water, and UV damage while maintaining flexibility. Nylon laminate typically involves bonding a thin film to the fabric, providing superior waterproofing and chemical resistance but potentially reducing breathability and flexibility. Coated nylon offers better wear resistance for heavy-duty use, whereas laminated nylon excels in environments requiring impermeability and chemical protection.

Applications of Nylon Coated Materials

Nylon coated materials are widely used in outdoor gear such as tents, backpacks, and rainwear due to their excellent water resistance and abrasion durability. This coating enhances fabric flexibility while maintaining breathability, making it ideal for sportswear and protective clothing applications. Industries like automotive and military also rely on nylon coated fabrics for their lightweight, durable, and weather-resistant properties.

Uses of Nylon Laminated Materials

Nylon laminated materials are extensively used in outdoor gear and protective clothing due to their enhanced water resistance and durability compared to nylon coatings. These laminates provide superior flexibility and breathability, making them ideal for applications such as tents, backpacks, and rainwear. Their multi-layer construction also offers increased abrasion resistance and chemical protection, catering to industrial and military gear requirements.

Performance in Different Environments

Nylon coating provides a durable, abrasion-resistant surface ideal for moderate moisture and mild chemical exposure, enhancing fabric flexibility and breathability. Nylon laminate offers superior waterproofing and wind resistance by bonding a thin layer of nylon film to the substrate, making it well-suited for harsh environments with heavy rain or strong winds. Performance differences arise as coated nylon excels in lightweight applications requiring durability and comfort, while laminated nylon is preferred for extreme weather protection due to its impermeable barrier.

Cost Analysis: Nylon Coating vs Nylon Laminate

Nylon coating typically offers a lower initial cost compared to nylon laminate due to simpler application processes and fewer material layers. Nylon laminate involves bonding multiple layers, increasing production complexity and overall expenses, but provides enhanced durability and waterproofing benefits. Evaluating cost-effectiveness depends on the specific application requirements, with nylon coating favored for budget-conscious projects and nylon laminate preferred for long-term performance investments.

Choosing the Right Material: Coating or Laminate?

Nylon coating involves applying a polymer layer to fabric surfaces, enhancing water resistance and durability without significantly altering fabric flexibility, ideal for lightweight outdoor gear. Nylon laminate consists of bonding multiple layers, creating a thicker, more robust barrier with superior waterproof and vapor-resistant properties, commonly used in protective clothing and heavy-duty applications. Choosing between coating and laminate depends on the required balance of breathability, weight, and durability for specific uses such as tents, backpacks, or rainwear.

Nylon Coating vs Nylon Laminate Infographic

materialdif.com

materialdif.com