Extrusion-grade nylon is formulated for continuous processes that require consistent melting and flow, making it ideal for producing fibers, films, and tubing with uniform thickness. Injection-molding-grade nylon, on the other hand, has enhanced thermal stability and controlled viscosity to withstand rapid cooling and high-pressure injection, resulting in precise, detailed parts with excellent surface finish. Selecting the appropriate grade ensures optimal mechanical properties, such as strength, flexibility, and durability, tailored to specific manufacturing techniques.

Table of Comparison

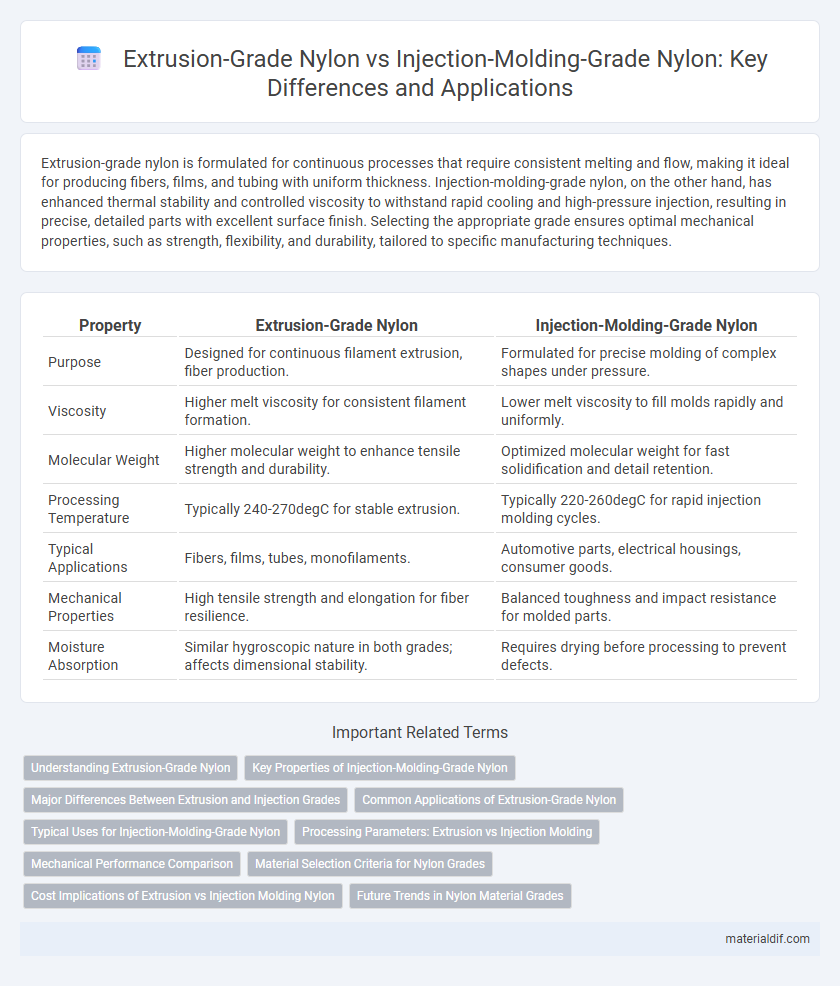

| Property | Extrusion-Grade Nylon | Injection-Molding-Grade Nylon |

|---|---|---|

| Purpose | Designed for continuous filament extrusion, fiber production. | Formulated for precise molding of complex shapes under pressure. |

| Viscosity | Higher melt viscosity for consistent filament formation. | Lower melt viscosity to fill molds rapidly and uniformly. |

| Molecular Weight | Higher molecular weight to enhance tensile strength and durability. | Optimized molecular weight for fast solidification and detail retention. |

| Processing Temperature | Typically 240-270degC for stable extrusion. | Typically 220-260degC for rapid injection molding cycles. |

| Typical Applications | Fibers, films, tubes, monofilaments. | Automotive parts, electrical housings, consumer goods. |

| Mechanical Properties | High tensile strength and elongation for fiber resilience. | Balanced toughness and impact resistance for molded parts. |

| Moisture Absorption | Similar hygroscopic nature in both grades; affects dimensional stability. | Requires drying before processing to prevent defects. |

Understanding Extrusion-Grade Nylon

Extrusion-grade Nylon is specifically formulated for high-temperature processing and continuous shaping into sheets, films, or fibers, offering superior melt strength and flow characteristics compared to injection-molding-grade Nylon. It exhibits enhanced thermal stability and resistance to degradation during the prolonged heat exposure of the extrusion process, making it ideal for applications requiring consistent dimensional tolerance and durability. Understanding the molecular weight distribution and additives in extrusion-grade Nylon is crucial for optimizing its performance in producing uniform, defect-free products.

Key Properties of Injection-Molding-Grade Nylon

Injection-molding-grade Nylon exhibits superior melt flow characteristics, allowing precise filling of complex mold geometries with minimal defects. Its higher thermal stability supports repeated heating cycles without significant degradation, ensuring consistent part performance. Enhanced impact resistance and dimensional stability make injection-molding-grade Nylon ideal for manufacturing durable, high-precision components in automotive, electronics, and consumer goods industries.

Major Differences Between Extrusion and Injection Grades

Extrusion-grade Nylon typically features higher molecular weight and enhanced flow properties tailored for continuous, uniform production of films, fibers, and tubing, while injection-molding-grade Nylon is formulated for rapid melting, precise filling of complex molds, and superior surface finish. The thermal and mechanical stability of extrusion-grade Nylon supports prolonged heating and shaping processes, contrasting with injection-grade Nylon's optimized viscosity and crystallization rates for quick cycle times and dimensional accuracy. Differences in additives and molecular structure also impact moisture absorption and impact resistance, aligning each grade with its specialized manufacturing method.

Common Applications of Extrusion-Grade Nylon

Extrusion-grade nylon is widely used in manufacturing flexible tubing, electrical wire insulation, and industrial films due to its excellent melt flow characteristics and thermal resistance. This type of nylon is preferred for continuous profile shapes and thin-walled products, making it ideal for automotive fuel lines, cable jackets, and packaging materials. Its durability and chemical resistance also suit applications in filtration membranes and conveyor belts.

Typical Uses for Injection-Molding-Grade Nylon

Injection-molding-grade nylon is commonly used for producing complex, high-strength automotive components, electrical housings, and consumer goods requiring precision and durability. This grade of nylon offers excellent dimensional stability and resistance to wear, making it ideal for small intricate parts requiring tight tolerances. Its versatility also extends to manufacturing gears, connectors, and various mechanical components in industrial applications.

Processing Parameters: Extrusion vs Injection Molding

Extrusion-grade Nylon typically requires higher melt temperatures ranging from 240degC to 270degC and increased screw speed to ensure uniform melting and consistent flow during the continuous extrusion process. Injection-molding-grade Nylon demands precise control of injection pressure between 800 to 1500 bar and mold temperature settings from 80degC to 120degC to achieve optimal dimensional stability and surface finish. Processing parameters such as screw design, cooling rate, and residence time are specifically tailored to suit extrusion for filament formation versus injection molding for complex geometries.

Mechanical Performance Comparison

Extrusion-grade nylon typically exhibits superior tensile strength and elongation properties compared to injection-molding-grade nylon, making it ideal for applications requiring continuous shaping and durability. Injection-molding-grade nylon offers enhanced impact resistance and dimensional stability, suitable for complex, precision components produced at high volume. Mechanical performance varies due to differences in molecular weight distribution and additive formulations tailored to each processing method.

Material Selection Criteria for Nylon Grades

Extrusion-grade Nylon exhibits higher melt strength and better thermal stability, making it ideal for continuous processes requiring uniform flow, whereas injection-molding-grade Nylon offers enhanced fluidity for intricate mold filling and faster cycle times. Material selection criteria for Nylon grades center around melt viscosity, crystallization rate, and mechanical property retention at elevated temperatures to ensure optimal performance in specific manufacturing methods. Key parameters such as molecular weight distribution and additive compatibility further influence the choice between extrusion-grade and injection-molding-grade Nylon for achieving desired product durability and finish.

Cost Implications of Extrusion vs Injection Molding Nylon

Extrusion-grade nylon generally offers lower material costs compared to injection-molding-grade nylon due to simpler processing and reduced waste. Injection molding requires higher precision and specialized resins, leading to increased raw material expenses and tooling costs. Overall, extrusion presents a cost-effective solution for producing continuous profiles, whereas injection molding suits complex parts but involves higher upfront investments.

Future Trends in Nylon Material Grades

Future trends in nylon material grades emphasize enhanced performance and sustainability, with extrusion-grade nylon evolving to deliver superior thermal stability and higher molecular weight for advanced filament applications. Injection-molding-grade nylon is being optimized for faster cycle times and improved impact resistance through nanoscale reinforcements and bio-based polymers. Innovations in recycling technologies and green chemistry are driving the development of next-generation nylons that balance mechanical strength with eco-friendly manufacturing processes.

Extrusion-grade Nylon vs Injection-molding-grade Nylon Infographic

materialdif.com

materialdif.com