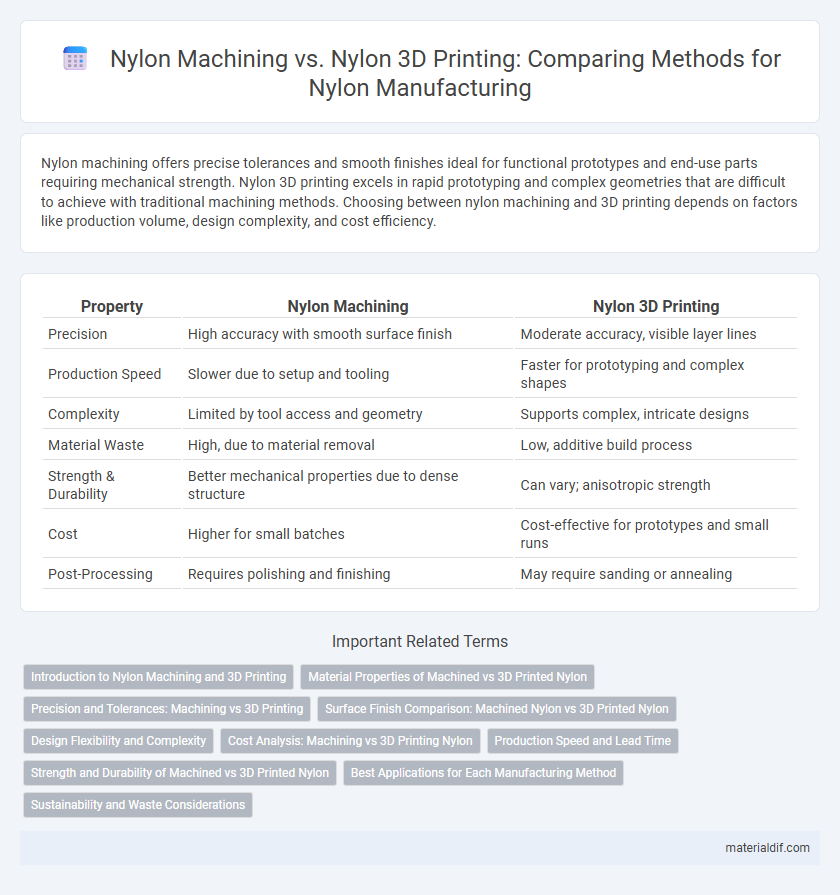

Nylon machining offers precise tolerances and smooth finishes ideal for functional prototypes and end-use parts requiring mechanical strength. Nylon 3D printing excels in rapid prototyping and complex geometries that are difficult to achieve with traditional machining methods. Choosing between nylon machining and 3D printing depends on factors like production volume, design complexity, and cost efficiency.

Table of Comparison

| Property | Nylon Machining | Nylon 3D Printing |

|---|---|---|

| Precision | High accuracy with smooth surface finish | Moderate accuracy, visible layer lines |

| Production Speed | Slower due to setup and tooling | Faster for prototyping and complex shapes |

| Complexity | Limited by tool access and geometry | Supports complex, intricate designs |

| Material Waste | High, due to material removal | Low, additive build process |

| Strength & Durability | Better mechanical properties due to dense structure | Can vary; anisotropic strength |

| Cost | Higher for small batches | Cost-effective for prototypes and small runs |

| Post-Processing | Requires polishing and finishing | May require sanding or annealing |

Introduction to Nylon Machining and 3D Printing

Nylon machining involves subtractive manufacturing techniques such as CNC milling and turning, delivering high precision and smooth surface finishes suitable for functional prototypes and end-use parts. Nylon 3D printing uses additive manufacturing methods like Selective Laser Sintering (SLS) or Fused Filament Fabrication (FFF), enabling complex geometries and rapid prototyping with strong, durable nylon-based filaments. Both processes offer distinct advantages depending on project requirements, with machining excelling in accuracy and surface quality while 3D printing provides design flexibility and faster iterations.

Material Properties of Machined vs 3D Printed Nylon

Machined nylon exhibits superior mechanical strength, surface finish, and dimensional accuracy compared to 3D printed nylon, which often contains micro-voids that reduce its tensile strength and impact resistance. The anisotropic properties of 3D printed nylon result in directional weaknesses, while machined nylon retains uniform properties throughout the part. Additionally, machined nylon offers better chemical resistance and wear properties, making it ideal for high-performance applications.

Precision and Tolerances: Machining vs 3D Printing

Nylon machining delivers superior precision and tighter tolerances, often achieving tolerances within +-0.001 inches, making it ideal for parts requiring exact dimensional accuracy. Nylon 3D printing, while versatile and cost-effective for prototypes, typically offers looser tolerances around +-0.005 inches due to layer resolution limitations. The choice between nylon machining and nylon 3D printing depends on the criticality of precision and tolerance requirements for the specific application.

Surface Finish Comparison: Machined Nylon vs 3D Printed Nylon

Machined nylon offers a superior surface finish characterized by smoothness and minimal layer lines, making it ideal for applications requiring high precision and aesthetic quality. In contrast, 3D printed nylon typically exhibits visible layer lines and a rougher texture due to the additive manufacturing process, which may require post-processing to improve surface smoothness. The choice between machining and 3D printing nylon depends on the desired surface finish quality, dimensional accuracy, and production volume.

Design Flexibility and Complexity

Nylon machining allows for precise dimensional accuracy and smooth surface finishes, making it ideal for parts with tight tolerances but limits geometric complexity due to tool accessibility constraints. Nylon 3D printing offers superior design flexibility, enabling the creation of intricate internal structures and complex geometries unattainable by conventional machining methods. Despite slightly rougher surface textures, 3D printing supports rapid prototyping and customization, accelerating product development for complex nylon components.

Cost Analysis: Machining vs 3D Printing Nylon

Nylon machining typically incurs higher initial tooling and labor costs due to precision cutting processes, making it more expensive for low-volume production runs. In contrast, nylon 3D printing offers lower upfront costs and faster prototyping capabilities, though material expenses and longer print times can increase overall prices for large-scale manufacturing. Cost efficiency depends on volume and complexity, with machining favored for high-precision, repetitive parts and 3D printing ideal for customized, low-quantity components.

Production Speed and Lead Time

Nylon machining typically offers faster production speeds for small to medium batches due to its precision cutting process and minimal post-processing requirements. In contrast, nylon 3D printing involves layer-by-layer fabrication, which increases lead time, especially for larger or more complex parts. Manufacturing lead times for CNC machined nylon parts can be as short as a few hours, whereas 3D printed nylon components often require several days to complete and cure.

Strength and Durability of Machined vs 3D Printed Nylon

Machined nylon offers superior strength and durability due to its dense, uniform molecular structure achieved through subtractive manufacturing, resulting in enhanced load-bearing capacity and resistance to impact. In contrast, 3D printed nylon parts may exhibit anisotropic strength and potential layer adhesion weaknesses, leading to reduced mechanical performance under stress. For applications demanding maximum structural integrity, machined nylon is the preferred choice over 3D printed counterparts.

Best Applications for Each Manufacturing Method

Nylon machining excels in producing high-precision, durable parts for industries like aerospace, automotive, and medical devices where tight tolerances and surface finish are critical. Nylon 3D printing offers rapid prototyping and complex geometries ideal for customized products, functional prototypes, and small batch production with intricate internal structures. Selecting the best method depends on factors such as production volume, design complexity, and mechanical requirements specific to the application.

Sustainability and Waste Considerations

Nylon machining generates significant material waste due to subtractive processes, leading to lower sustainability compared to nylon 3D printing, which uses additive manufacturing that minimizes excess material. Nylon 3D printing allows precise material deposition, reducing scrap and enabling the use of recycled nylon powders, further enhancing environmental benefits. This sustainable approach contrasts with machining's typically higher energy consumption and difficulty in recycling offcuts.

Nylon Machining vs Nylon 3D Printing Infographic

materialdif.com

materialdif.com