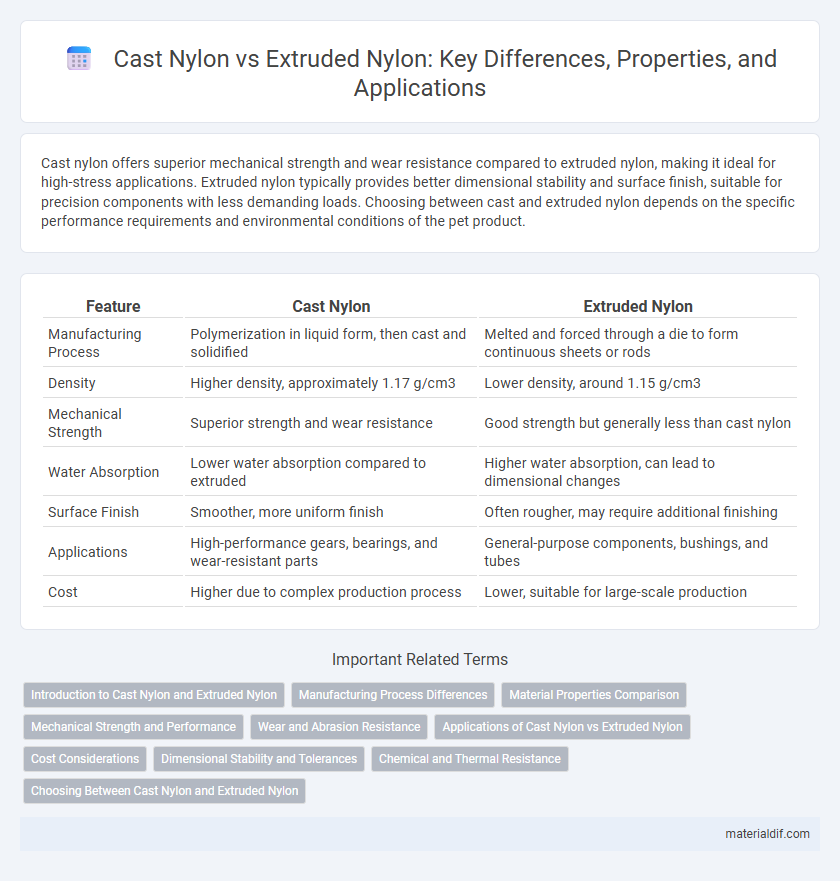

Cast nylon offers superior mechanical strength and wear resistance compared to extruded nylon, making it ideal for high-stress applications. Extruded nylon typically provides better dimensional stability and surface finish, suitable for precision components with less demanding loads. Choosing between cast and extruded nylon depends on the specific performance requirements and environmental conditions of the pet product.

Table of Comparison

| Feature | Cast Nylon | Extruded Nylon |

|---|---|---|

| Manufacturing Process | Polymerization in liquid form, then cast and solidified | Melted and forced through a die to form continuous sheets or rods |

| Density | Higher density, approximately 1.17 g/cm3 | Lower density, around 1.15 g/cm3 |

| Mechanical Strength | Superior strength and wear resistance | Good strength but generally less than cast nylon |

| Water Absorption | Lower water absorption compared to extruded | Higher water absorption, can lead to dimensional changes |

| Surface Finish | Smoother, more uniform finish | Often rougher, may require additional finishing |

| Applications | High-performance gears, bearings, and wear-resistant parts | General-purpose components, bushings, and tubes |

| Cost | Higher due to complex production process | Lower, suitable for large-scale production |

Introduction to Cast Nylon and Extruded Nylon

Cast nylon is produced through a casting process, resulting in a dense, strong material with excellent wear resistance and dimensional stability, ideal for heavy-duty industrial applications. Extruded nylon, created by melting and forcing the polymer through a die, offers uniform thickness and is commonly used for components requiring consistent mechanical properties and smooth finishes. Both types provide excellent toughness and chemical resistance, but the choice depends on the specific performance requirements and manufacturing constraints of the application.

Manufacturing Process Differences

Cast nylon is produced through a polymerization process where caprolactam monomers are polymerized in a mold, resulting in a dense and uniform material with enhanced mechanical properties and dimensional stability. Extruded nylon is made by melting nylon pellets and forcing the molten polymer through a die, creating continuous shapes with typically less uniformity and lower mechanical strength compared to cast nylon. The casting process allows for complex shapes and superior structural integrity, whereas extrusion excels in high-volume, continuous profile production.

Material Properties Comparison

Cast nylon exhibits superior mechanical strength, higher wear resistance, and better chemical resistance compared to extruded nylon, making it ideal for heavy-duty industrial applications. Extruded nylon offers more consistent dimensional stability and is easier to machine, suitable for precision parts requiring tight tolerances. Both materials have similar thermal properties, but cast nylon's enhanced toughness ensures improved performance under compressive and impact loads.

Mechanical Strength and Performance

Cast nylon exhibits superior mechanical strength compared to extruded nylon due to its higher density and reduced internal stresses, resulting in enhanced toughness and wear resistance. Extruded nylon, while slightly less strong, offers consistent dimensional stability and is ideal for applications requiring uniformity and ease of fabrication. Both types provide excellent chemical resistance and impact performance, but cast nylon is preferred for heavy-duty mechanical components subjected to high load and friction.

Wear and Abrasion Resistance

Cast nylon exhibits superior wear and abrasion resistance compared to extruded nylon due to its denser molecular structure and fewer internal stresses. This enhanced durability makes cast nylon ideal for high-load bearings, gears, and wear strips in industrial applications. Extruded nylon offers good abrasion resistance as well but may experience higher wear rates under continuous friction or heavy mechanical stress.

Applications of Cast Nylon vs Extruded Nylon

Cast nylon offers superior machinability and abrasion resistance, making it ideal for applications requiring complex shapes and high durability, such as gears, bearings, and wear pads. Extruded nylon, known for its consistent mechanical properties and versatility, is commonly used in rods, sheets, and tubes for general engineering purposes like automotive components and conveyor parts. Both types serve critical roles in manufacturing, with cast nylon preferred for precision and wear-critical applications while extruded nylon suits mass production and structural uses.

Cost Considerations

Cast nylon typically incurs higher production costs than extruded nylon due to its more complex manufacturing process and superior material properties. Extruded nylon offers a cost-effective solution for applications requiring large quantities and consistent dimensional tolerances, making it suitable for mass production. Selecting between cast and extruded nylon depends on budget constraints balanced against performance requirements and end-use conditions.

Dimensional Stability and Tolerances

Cast nylon offers superior dimensional stability compared to extruded nylon due to its controlled solidification process, resulting in less internal stress and shrinkage. Tolerances in cast nylon are typically tighter, allowing for more precise machining and consistent part dimensions. Extruded nylon, while more cost-effective, can exhibit greater variation in dimensions and slightly looser tolerances due to the nature of its continuous forming process.

Chemical and Thermal Resistance

Cast nylon exhibits superior chemical resistance compared to extruded nylon, making it highly effective against oils, fuels, and solvents commonly used in industrial applications. Thermal resistance in cast nylon is enhanced due to its denser molecular structure, allowing it to maintain mechanical properties at elevated temperatures up to 260degF (127degC). Extruded nylon, while offering good thermal stability around 230degF (110degC), is more prone to chemical degradation, especially in harsh acidic or alkaline environments.

Choosing Between Cast Nylon and Extruded Nylon

Choosing between cast nylon and extruded nylon depends on the specific application requirements, such as mechanical strength, dimensional stability, and resistance to wear. Cast nylon offers superior impact resistance and better performance under heavy loads due to its uniform molecular structure, making it ideal for high-stress applications. Extruded nylon, while generally more cost-effective and easier to machine, provides consistent dimensional tolerance suitable for parts requiring precise dimensions but is less resistant to impact and wear compared to cast nylon.

Cast nylon vs Extruded nylon Infographic

materialdif.com

materialdif.com