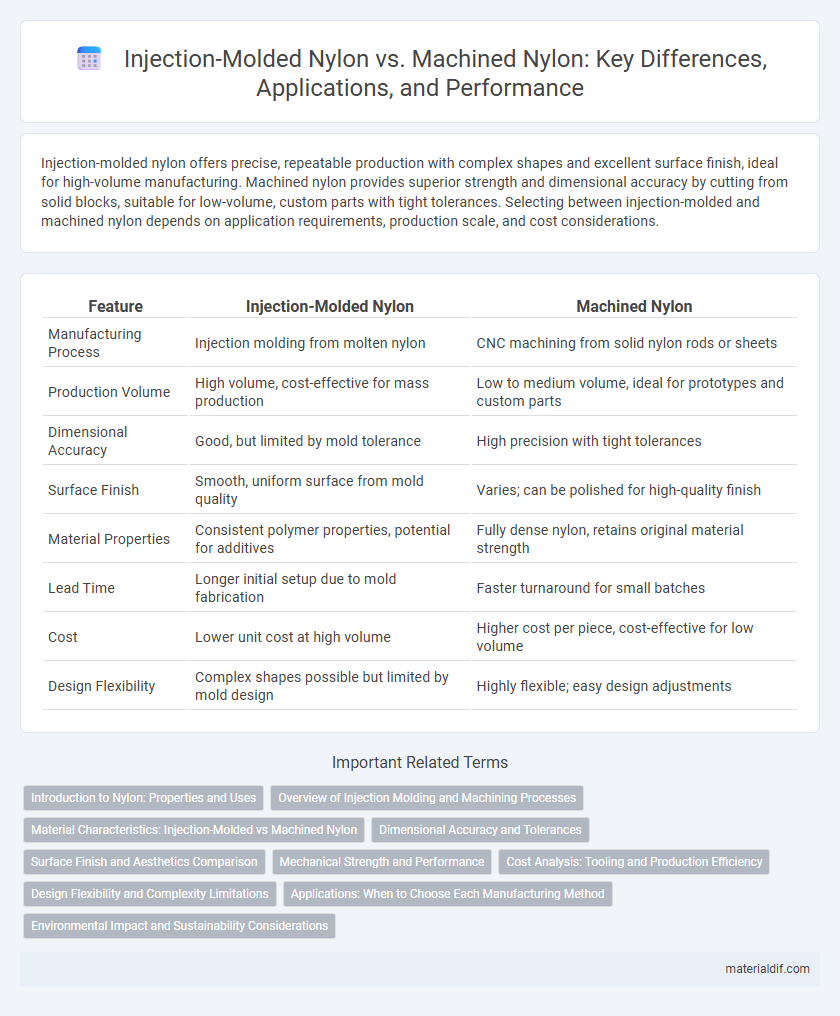

Injection-molded nylon offers precise, repeatable production with complex shapes and excellent surface finish, ideal for high-volume manufacturing. Machined nylon provides superior strength and dimensional accuracy by cutting from solid blocks, suitable for low-volume, custom parts with tight tolerances. Selecting between injection-molded and machined nylon depends on application requirements, production scale, and cost considerations.

Table of Comparison

| Feature | Injection-Molded Nylon | Machined Nylon |

|---|---|---|

| Manufacturing Process | Injection molding from molten nylon | CNC machining from solid nylon rods or sheets |

| Production Volume | High volume, cost-effective for mass production | Low to medium volume, ideal for prototypes and custom parts |

| Dimensional Accuracy | Good, but limited by mold tolerance | High precision with tight tolerances |

| Surface Finish | Smooth, uniform surface from mold quality | Varies; can be polished for high-quality finish |

| Material Properties | Consistent polymer properties, potential for additives | Fully dense nylon, retains original material strength |

| Lead Time | Longer initial setup due to mold fabrication | Faster turnaround for small batches |

| Cost | Lower unit cost at high volume | Higher cost per piece, cost-effective for low volume |

| Design Flexibility | Complex shapes possible but limited by mold design | Highly flexible; easy design adjustments |

Introduction to Nylon: Properties and Uses

Injection-molded nylon offers high strength, excellent wear resistance, and precise dimensional stability, making it ideal for mass-produced components in automotive and consumer goods. Machined nylon, derived from extruded sheets or rods, provides superior customization, allowing for complex geometries and tighter tolerances in prototypes and low-volume production. Both forms leverage nylon's inherent properties such as chemical resistance, low friction, and impact toughness, crucial for engineering applications requiring durability and versatility.

Overview of Injection Molding and Machining Processes

Injection molding of nylon involves melting polymer pellets and injecting the molten material into a precision-engineered mold cavity, allowing rapid production of complex, high-volume parts with consistent dimensional accuracy. Machining nylon starts with solid nylon blocks or rods, where subtractive manufacturing techniques like CNC milling or turning remove material to achieve the final shape, providing high customization and tight tolerances for low to medium production runs. Injection molding excels in speed and repeatability for parts like gears and housings, while machining offers flexibility and fine detail for prototypes and specialized components.

Material Characteristics: Injection-Molded vs Machined Nylon

Injection-molded nylon exhibits uniform density and superior dimensional stability due to high-pressure fabrication, making it ideal for complex, high-volume parts with consistent mechanical properties. Machined nylon retains natural grain and may present slight variability in strength and surface finish, offering better control for custom, low-volume components requiring intricate detailing. Both methods impact moisture absorption rates and tensile strength, with injection molding typically resulting in enhanced durability and reduced warping in nylon products.

Dimensional Accuracy and Tolerances

Injection-molded nylon offers high production efficiency but typically exhibits less dimensional accuracy and wider tolerances due to material shrinkage during cooling. Machined nylon parts provide superior dimensional precision with tighter tolerances, ideal for applications requiring exact fits and critical measurements. Selecting between injection-molded and machined nylon depends on the balance between cost-effectiveness and the need for precise dimensional control.

Surface Finish and Aesthetics Comparison

Injection-molded nylon provides a smoother and more consistent surface finish due to the precision of the molding process, resulting in aesthetically pleasing parts with minimal post-processing. Machined nylon often displays tool marks and may require additional polishing to achieve comparable surface quality, which can affect the visual appeal. The injection molding method excels in producing complex shapes with uniform texture, making it ideal for applications where surface finish and aesthetics are critical.

Mechanical Strength and Performance

Injection-molded nylon offers enhanced mechanical strength due to uniform molecular orientation and lower residual stresses, resulting in superior impact resistance and dimensional stability. Machined nylon, while precise in tolerances, may exhibit lower performance under dynamic loads because of machining-induced surface imperfections and potential internal stress concentrations. Choosing injection-molded nylon optimizes long-term durability and load-bearing capacity in demanding engineering applications.

Cost Analysis: Tooling and Production Efficiency

Injection-molded nylon offers lower per-part costs due to high production efficiency and reduced labor through automated processes, despite higher initial tooling expenses for mold creation. Machined nylon incurs minimal upfront tooling costs but results in increased labor expenses and slower production rates, leading to higher costs in large volume manufacturing. Evaluating project scale and budget constraints is crucial when choosing between injection-molded and machined nylon components.

Design Flexibility and Complexity Limitations

Injection-molded nylon offers superior design flexibility with the ability to create intricate shapes and complex geometries that are difficult to achieve through machining. Machined nylon is limited by tool access and geometry constraints, making it less suitable for parts with complex internal features or undercuts. This makes injection molding the preferred method for high-volume production requiring detailed and precise nylon components.

Applications: When to Choose Each Manufacturing Method

Injection-molded nylon is ideal for high-volume production of complex shapes used in automotive parts, electrical connectors, and consumer goods due to its cost-efficiency and design flexibility. Machined nylon suits low-volume or prototype applications requiring precise tolerances, such as custom gears, bearings, and electrical insulators. Selecting between the two depends on factors like production scale, dimensional accuracy, and part complexity.

Environmental Impact and Sustainability Considerations

Injection-molded nylon typically generates less waste during production compared to machined nylon, which involves cutting away excess material and results in higher scrap rates. The energy consumption for injection molding is generally lower due to faster cycle times and automation, contributing to a reduced carbon footprint. Recyclability of both forms depends on nylon type, but injection-molded nylon parts often allow for easier collection and reuse, enhancing overall sustainability.

Injection-Molded Nylon vs Machined Nylon Infographic

materialdif.com

materialdif.com