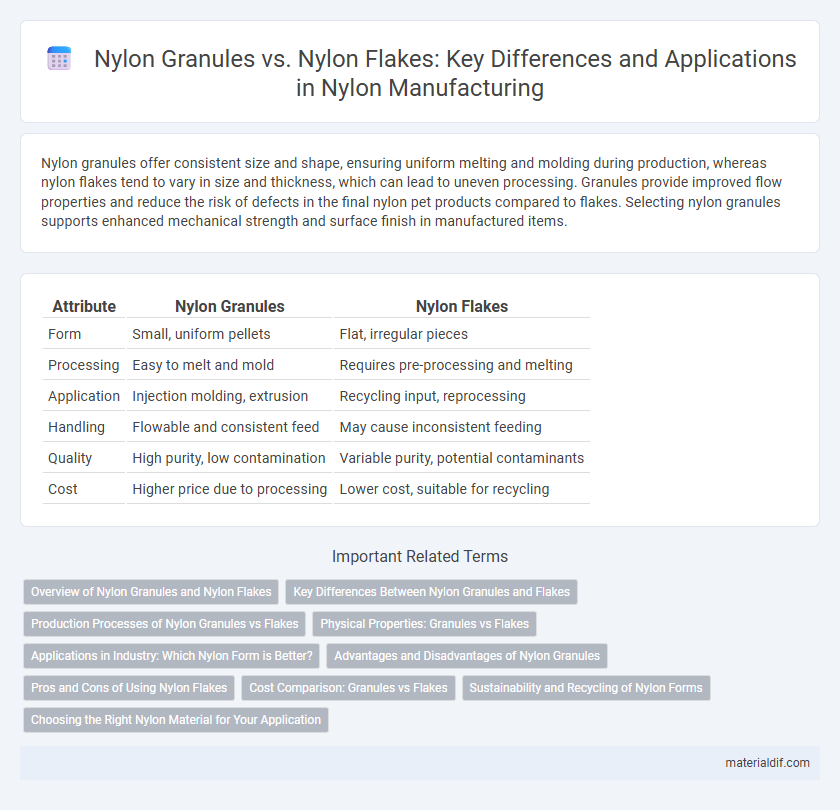

Nylon granules offer consistent size and shape, ensuring uniform melting and molding during production, whereas nylon flakes tend to vary in size and thickness, which can lead to uneven processing. Granules provide improved flow properties and reduce the risk of defects in the final nylon pet products compared to flakes. Selecting nylon granules supports enhanced mechanical strength and surface finish in manufactured items.

Table of Comparison

| Attribute | Nylon Granules | Nylon Flakes |

|---|---|---|

| Form | Small, uniform pellets | Flat, irregular pieces |

| Processing | Easy to melt and mold | Requires pre-processing and melting |

| Application | Injection molding, extrusion | Recycling input, reprocessing |

| Handling | Flowable and consistent feed | May cause inconsistent feeding |

| Quality | High purity, low contamination | Variable purity, potential contaminants |

| Cost | Higher price due to processing | Lower cost, suitable for recycling |

Overview of Nylon Granules and Nylon Flakes

Nylon granules are small, uniformly shaped pellets used as raw material in injection molding and extrusion processes, offering consistent flow characteristics and superior mechanical properties in finished products. Nylon flakes, typically derived from recycled nylon, are irregularly shaped and require melting or reprocessing before use, making them ideal for cost-effective manufacturing and sustainable production cycles. Both forms play crucial roles in the nylon supply chain, with granules favored for precision applications and flakes valued for recycling efficiency and environmental impact reduction.

Key Differences Between Nylon Granules and Flakes

Nylon granules are small, uniform pellets that offer consistent melting behavior and are ideal for precise molding and extrusion processes, whereas nylon flakes are irregularly shaped and primarily used in recycling or as a raw material for reprocessing. Granules provide better flow properties and easier dosing in manufacturing compared to the more variable size and moisture content of flakes. The choice between granules and flakes directly impacts product quality, processing efficiency, and material handling in nylon production.

Production Processes of Nylon Granules vs Flakes

Nylon granules are produced through a controlled polymerization process followed by pelletizing, resulting in uniform, solid pellets ideal for consistent feeding in extrusion and injection molding. Nylon flakes originate from shredded or chipped recycled nylon products, requiring additional washing and drying stages to remove contaminants and moisture before reprocessing. The production of granules emphasizes precision and purity for manufacturing efficiency, while flakes focus on recycling and material recovery for sustainable reuse.

Physical Properties: Granules vs Flakes

Nylon granules exhibit uniform size and shape, providing consistent melting behavior and better flow properties during processing compared to irregularly shaped nylon flakes. The higher density and controlled moisture content in granules contribute to superior mechanical strength and dimensional stability in the final products. Nylon flakes tend to have higher surface area, leading to increased moisture absorption and variability in thermal properties, which can affect the quality and consistency of molded parts.

Applications in Industry: Which Nylon Form is Better?

Nylon granules offer superior uniformity and melt flow, making them ideal for precision injection molding and 3D printing in automotive and consumer goods industries. Nylon flakes require additional processing, which benefits recyclers and manufacturers focused on sustainable production but may introduce variability in final product quality. The choice depends on the application's demand for consistency, production scale, and environmental considerations.

Advantages and Disadvantages of Nylon Granules

Nylon granules offer superior flowability and consistent melting behavior compared to nylon flakes, enhancing precision in injection molding and extrusion processes. However, granules typically incur higher processing costs and may have limited surface area for additive absorption relative to flakes. The improved uniformity of granules reduces contamination risks and improves mechanical properties of the final product, making them preferable for high-quality, performance-critical applications.

Pros and Cons of Using Nylon Flakes

Nylon flakes offer advantages such as easier melting and mixing due to their irregular shape and higher surface area compared to uniform nylon granules. However, nylon flakes can lead to inconsistent melting and potential contamination, which may affect the mechanical properties of the final product. The choice between flakes and granules depends on processing requirements, with flakes providing greater flexibility in customized melting processes but requiring more careful control to ensure uniform quality.

Cost Comparison: Granules vs Flakes

Nylon granules generally have a higher cost compared to nylon flakes due to their refined processing and uniform size, which enhances consistency in molding applications. Nylon flakes, being less processed, are more economical but may require additional steps for melting and homogenization in manufacturing. The choice between granules and flakes depends on balancing upfront material costs with processing efficiency and product quality requirements.

Sustainability and Recycling of Nylon Forms

Nylon granules offer enhanced recyclability due to their uniform size and shape, facilitating consistent melting and remolding in sustainable manufacturing processes. Nylon flakes, derived from shredded post-consumer waste, support circular economy efforts by enabling the reuse of diverse nylon sources, albeit requiring more intensive cleaning and sorting. Both forms contribute to reducing plastic waste, but granules provide greater efficiency in closed-loop recycling systems, minimizing energy consumption and material degradation.

Choosing the Right Nylon Material for Your Application

Nylon granules offer consistent particle size and superior flow properties, making them ideal for injection molding and precision manufacturing processes. Nylon flakes, with their irregular shape and larger surface area, are better suited for recycling and blending applications where enhanced melting and mixing are required. Selecting between granules and flakes depends on your production method, desired finish quality, and specific mechanical property needs.

Nylon granules vs Nylon flakes Infographic

materialdif.com

materialdif.com