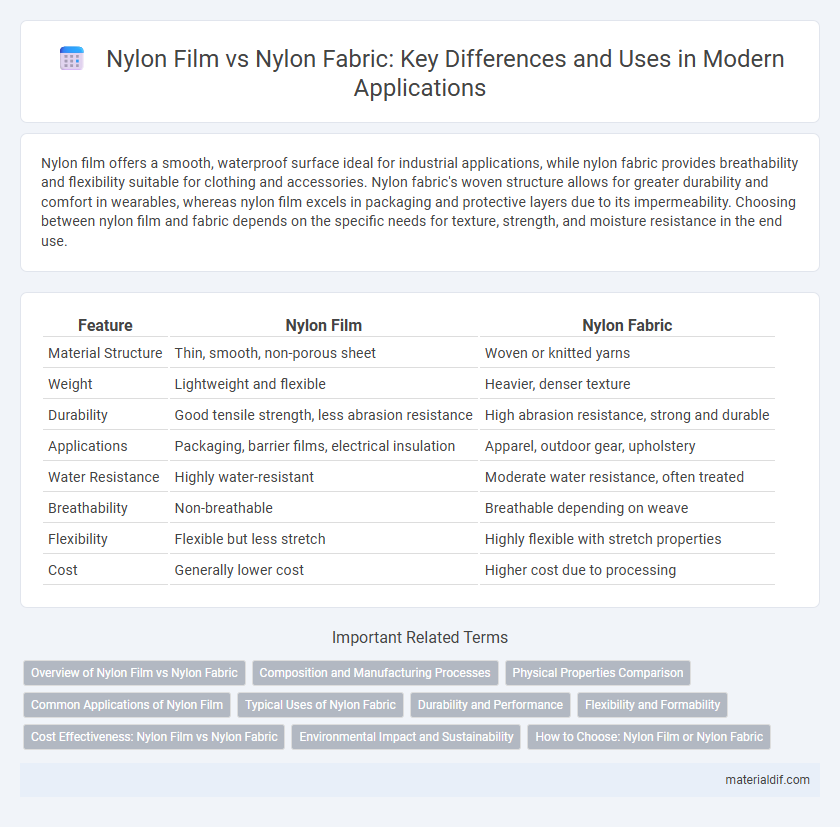

Nylon film offers a smooth, waterproof surface ideal for industrial applications, while nylon fabric provides breathability and flexibility suitable for clothing and accessories. Nylon fabric's woven structure allows for greater durability and comfort in wearables, whereas nylon film excels in packaging and protective layers due to its impermeability. Choosing between nylon film and fabric depends on the specific needs for texture, strength, and moisture resistance in the end use.

Table of Comparison

| Feature | Nylon Film | Nylon Fabric |

|---|---|---|

| Material Structure | Thin, smooth, non-porous sheet | Woven or knitted yarns |

| Weight | Lightweight and flexible | Heavier, denser texture |

| Durability | Good tensile strength, less abrasion resistance | High abrasion resistance, strong and durable |

| Applications | Packaging, barrier films, electrical insulation | Apparel, outdoor gear, upholstery |

| Water Resistance | Highly water-resistant | Moderate water resistance, often treated |

| Breathability | Non-breathable | Breathable depending on weave |

| Flexibility | Flexible but less stretch | Highly flexible with stretch properties |

| Cost | Generally lower cost | Higher cost due to processing |

Overview of Nylon Film vs Nylon Fabric

Nylon film is a thin, transparent or translucent plastic sheet known for its excellent barrier properties, high tensile strength, and flexibility, commonly used in packaging, electronics, and industrial applications. Nylon fabric, a woven or knitted textile made from nylon fibers, offers durability, elasticity, abrasion resistance, and moisture-wicking capabilities, widely utilized in apparel, outdoor gear, and upholstery. Both materials derive from polyamide polymers but differ in structure and performance, with nylon film emphasizing protective and barrier functions while nylon fabric focuses on comfort, breathability, and wear resistance.

Composition and Manufacturing Processes

Nylon film is typically produced through a casting or extrusion process, resulting in thin, flexible sheets made primarily from polyamide polymers, offering excellent barrier properties and mechanical strength. Nylon fabric, on the other hand, is manufactured by spinning nylon fibers into yarns, which are then woven or knitted to create textiles known for durability, elasticity, and breathability. Both materials share the common polyamide composition but differ significantly in their structural form and production techniques, influencing their application in packaging versus textile industries.

Physical Properties Comparison

Nylon film exhibits high tensile strength, excellent chemical resistance, and superior barrier properties against moisture and gases, making it ideal for packaging applications. Nylon fabric offers enhanced flexibility, breathability, and abrasion resistance, suited for textiles and apparel. The film's smooth, non-porous surface contrasts with the fabric's porous, woven structure, influencing their respective durability and usability in various industries.

Common Applications of Nylon Film

Nylon film is widely used in packaging industries due to its excellent barrier properties against oxygen, moisture, and aromas, making it ideal for food preservation and medical packaging. It also finds applications in electronics for insulation films and protective layering because of its durability and thermal resistance. Compared to nylon fabric, which is primarily utilized in textiles, apparel, and industrial sewing threads, nylon film emphasizes functional uses in protective and packaging solutions.

Typical Uses of Nylon Fabric

Nylon fabric is commonly used in apparel such as activewear, lingerie, and outerwear due to its excellent strength, elasticity, and moisture-wicking properties. It is also widely utilized in industrial applications including ropes, parachutes, and sails because of its durability and resistance to abrasion. Unlike nylon film, which is primarily employed in packaging and protective coatings, nylon fabric serves as a versatile textile solution in both consumer and commercial products.

Durability and Performance

Nylon film exhibits exceptional durability due to its high tensile strength, abrasion resistance, and moisture barrier properties, making it ideal for packaging and protective applications. Nylon fabric offers superior performance in flexibility, breathability, and stretch, which is essential for apparel and outdoor gear requiring comfort and resilience. Both materials deliver strong wear resistance, but nylon film is preferred for durable protective layers, while fabric excels in dynamic, wearable uses.

Flexibility and Formability

Nylon film exhibits superior flexibility due to its thin, smooth structure, allowing for easy bending and shaping without damage, making it ideal for packaging and thin-layer applications. In contrast, Nylon fabric offers greater formability, with a woven or knit construction that supports stretching, draping, and tailored shaping essential for apparel and textile products. The molecular orientation in Nylon films enhances tensile strength and elasticity, while the interlaced fibers in Nylon fabrics provide durability and adaptability in various forms.

Cost Effectiveness: Nylon Film vs Nylon Fabric

Nylon film offers higher cost effectiveness due to its lower raw material and production costs compared to nylon fabric, making it ideal for packaging and industrial applications where budget constraints are critical. Nylon fabric involves more complex manufacturing processes such as weaving and dyeing, which increase labor and processing expenses, thus raising its overall price. For applications prioritizing durability and flexibility at a reduced cost, nylon film presents a more economical choice than nylon fabric.

Environmental Impact and Sustainability

Nylon film and nylon fabric both have significant environmental footprints due to their petroleum-based origins, but nylon fabric often entails higher resource consumption during production and typically has a longer lifecycle contributing to greater waste accumulation. Nylon film, used primarily in packaging, offers benefits like reduced material usage and enhanced recyclability, though its environmental impact depends heavily on local recycling infrastructure. Innovations in bio-based nylon and improved recycling technologies are essential for reducing the carbon emissions and non-biodegradable waste associated with both forms.

How to Choose: Nylon Film or Nylon Fabric

Choosing between nylon film and nylon fabric depends on the intended use and performance requirements; nylon film offers excellent barrier properties, moisture resistance, and strength, making it ideal for packaging and protective coatings. Nylon fabric provides durability, flexibility, and breathability suitable for apparel, outdoor gear, and industrial applications where comfort and pliability are essential. Consider the specific attributes such as tensile strength, transparency, and ease of processing to select the optimal nylon form for your project.

Nylon film vs Nylon fabric Infographic

materialdif.com

materialdif.com