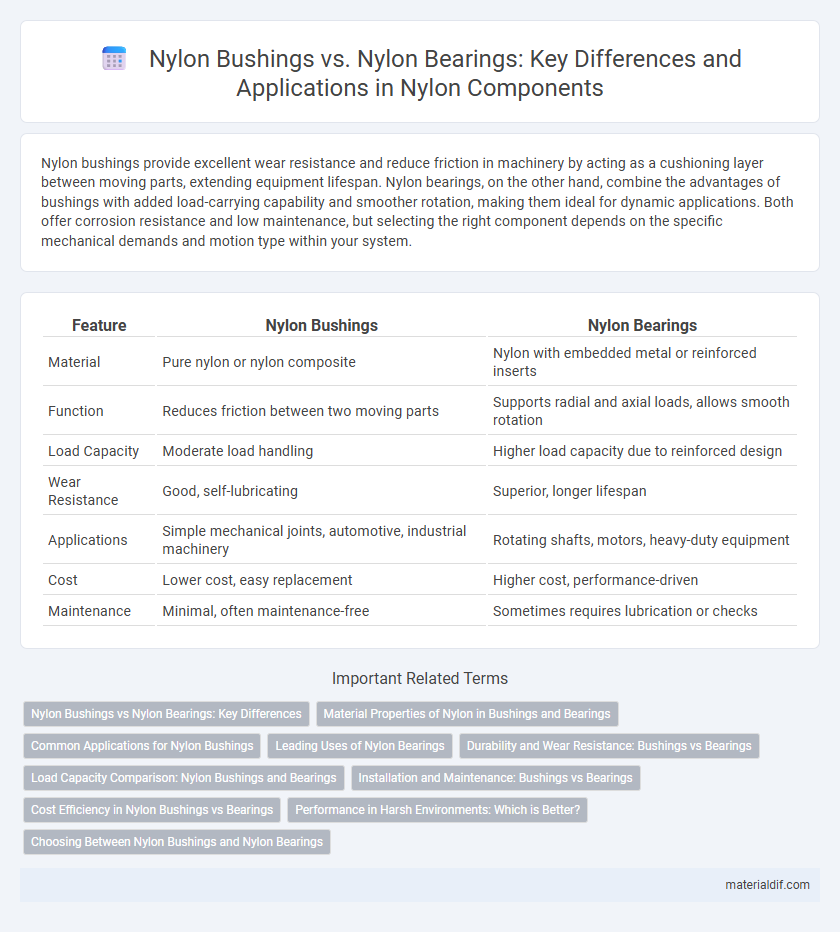

Nylon bushings provide excellent wear resistance and reduce friction in machinery by acting as a cushioning layer between moving parts, extending equipment lifespan. Nylon bearings, on the other hand, combine the advantages of bushings with added load-carrying capability and smoother rotation, making them ideal for dynamic applications. Both offer corrosion resistance and low maintenance, but selecting the right component depends on the specific mechanical demands and motion type within your system.

Table of Comparison

| Feature | Nylon Bushings | Nylon Bearings |

|---|---|---|

| Material | Pure nylon or nylon composite | Nylon with embedded metal or reinforced inserts |

| Function | Reduces friction between two moving parts | Supports radial and axial loads, allows smooth rotation |

| Load Capacity | Moderate load handling | Higher load capacity due to reinforced design |

| Wear Resistance | Good, self-lubricating | Superior, longer lifespan |

| Applications | Simple mechanical joints, automotive, industrial machinery | Rotating shafts, motors, heavy-duty equipment |

| Cost | Lower cost, easy replacement | Higher cost, performance-driven |

| Maintenance | Minimal, often maintenance-free | Sometimes requires lubrication or checks |

Nylon Bushings vs Nylon Bearings: Key Differences

Nylon bushings serve as cylindrical sleeves that reduce friction and wear between moving parts, offering high resistance to abrasion and chemical corrosion. Nylon bearings, however, are designed to support rotational motion by accommodating radial and axial loads with enhanced load distribution and low friction coefficients. The key differences lie in their structure and application: bushings typically provide a fixed interface for shafts, while bearings facilitate smoother rotational movement with minimal maintenance.

Material Properties of Nylon in Bushings and Bearings

Nylon bushings and bearings leverage the high wear resistance, low friction coefficient, and excellent chemical stability of nylon, making them ideal for reducing friction and extending machinery life. The inherent toughness and self-lubricating properties of nylon enable these components to perform well under dynamic loads, even in harsh environments with exposure to oils, solvents, and moisture. Superior dimensional stability and impact resistance further enhance the reliability of nylon bushings and bearings in applications requiring prolonged durability and minimal maintenance.

Common Applications for Nylon Bushings

Nylon bushings are widely used in automotive components, industrial machinery, and electrical equipment due to their high wear resistance and low friction properties. They provide excellent vibration damping and electrical insulation in applications such as gearboxes, conveyor systems, and motors. Common industries utilizing nylon bushings include manufacturing, agriculture, and aerospace for components requiring durability and low maintenance.

Leading Uses of Nylon Bearings

Nylon bearings excel in applications requiring low friction, corrosion resistance, and high load capacity, making them ideal for automotive components, conveyor systems, and industrial machinery. Unlike nylon bushings, which primarily provide cushioning and alignment, nylon bearings offer smooth rotational movement and enhanced durability under repetitive motion. Their resistance to wear and chemicals positions them as the preferred choice in manufacturing environments demanding consistent performance and minimal maintenance.

Durability and Wear Resistance: Bushings vs Bearings

Nylon bushings offer superior durability and wear resistance compared to nylon bearings due to their solid, shock-absorbing construction that evenly distributes load and reduces friction. Nylon bearings, often containing embedded steel or ceramic balls, provide smoother rotational movement but can experience faster wear under high-load or abrasive conditions. Selecting nylon bushings ensures longer service life and enhanced performance in heavy-duty applications requiring consistent wear resistance.

Load Capacity Comparison: Nylon Bushings and Bearings

Nylon bushings typically offer higher load capacity due to their solid cylindrical design, which provides greater surface area for load distribution compared to nylon bearings. Nylon bearings, often incorporating ball or roller elements, excel in reducing friction but may have lower load tolerance under heavy, static loads. The choice between nylon bushings and bearings depends on the application's load requirements and movement dynamics, with bushings favored for heavier load support and bearings for enhanced rotational efficiency.

Installation and Maintenance: Bushings vs Bearings

Nylon bushings require straightforward installation, often press-fitted into housings without the need for additional lubrication, making maintenance minimal and cost-effective. In contrast, nylon bearings, equipped with rolling elements, demand precise alignment during installation and periodic lubrication to ensure smooth operation and prolonged lifespan. Maintenance for nylon bushings typically involves simple inspection and cleaning, while nylon bearings require regular lubrication checks and potential replacement of worn rolling components.

Cost Efficiency in Nylon Bushings vs Bearings

Nylon bushings offer superior cost efficiency compared to nylon bearings due to their simpler design and lower manufacturing costs, making them ideal for budget-sensitive applications with light to moderate loads. Their reduced maintenance requirements and longer service life also contribute to overall savings by minimizing downtime and replacement expenses. Nylon bearings, while providing better performance under heavy loads and higher speeds, typically incur higher initial and upkeep costs, limiting their economic advantage in cost-conscious projects.

Performance in Harsh Environments: Which is Better?

Nylon bushings offer superior resistance to wear and chemical exposure in harsh environments, making them ideal for applications with high friction and heavy loads. Nylon bearings provide smoother rotational performance and reduced noise but may be less durable under extreme conditions due to their design. For heavy-duty and abrasive environments, nylon bushings generally outperform nylon bearings in longevity and reliability.

Choosing Between Nylon Bushings and Nylon Bearings

Nylon bushings offer a low-friction, wear-resistant solution ideal for applications with limited space and moderate loads, providing excellent vibration dampening and electrical insulation. Nylon bearings typically incorporate rolling elements for enhanced load capacity and reduced rotational resistance, making them suitable for higher-speed or heavier-load scenarios. Choosing between nylon bushings and nylon bearings depends on specific application requirements including load, speed, maintenance needs, and environmental conditions.

Nylon bushings vs Nylon bearings Infographic

materialdif.com

materialdif.com