Melt-spinning of nylon pet involves melting the polymer and extruding it through spinnerets to form fibers, offering a cost-effective and efficient production method with strong mechanical properties. Solution-spinning dissolves nylon pet in a suitable solvent before extrusion, enabling finer control over fiber morphology and enhanced fiber uniformity but at higher processing costs. The choice between melt-spinning and solution-spinning impacts the nylon pet's texture, strength, and application performance in textiles and industrial uses.

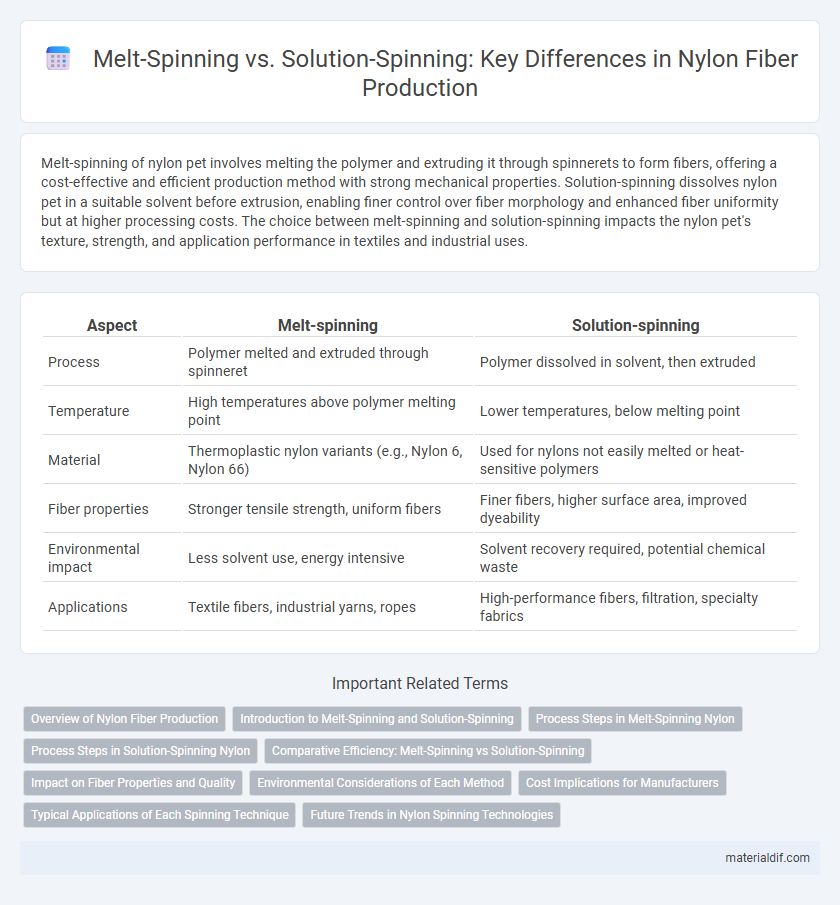

Table of Comparison

| Aspect | Melt-spinning | Solution-spinning |

|---|---|---|

| Process | Polymer melted and extruded through spinneret | Polymer dissolved in solvent, then extruded |

| Temperature | High temperatures above polymer melting point | Lower temperatures, below melting point |

| Material | Thermoplastic nylon variants (e.g., Nylon 6, Nylon 66) | Used for nylons not easily melted or heat-sensitive polymers |

| Fiber properties | Stronger tensile strength, uniform fibers | Finer fibers, higher surface area, improved dyeability |

| Environmental impact | Less solvent use, energy intensive | Solvent recovery required, potential chemical waste |

| Applications | Textile fibers, industrial yarns, ropes | High-performance fibers, filtration, specialty fabrics |

Overview of Nylon Fiber Production

Nylon fiber production primarily involves two spinning methods: melt-spinning and solution-spinning, each with distinct processes and applications. Melt-spinning heats and extrudes molten nylon through spinnerets to form fibers, making it ideal for producing strong, uniform filaments commonly used in textiles and industrial products. Solution-spinning dissolves nylon polymers in a solvent before extrusion, enabling the production of fine, high-performance fibers with enhanced properties for specialized applications.

Introduction to Melt-Spinning and Solution-Spinning

Melt-spinning involves melting nylon polymer pellets and extruding them through a spinneret to form continuous filaments, followed by rapid cooling to solidify the fibers. Solution-spinning dissolves nylon polymers in a suitable solvent, then extrudes the solution through spinnerets into a coagulation bath, where the fibers are regenerated as the solvent is removed. Each process impacts the fiber's mechanical properties and applications, with melt-spinning favored for cost efficiency and solution-spinning used for higher-performance fibers.

Process Steps in Melt-Spinning Nylon

Melt-spinning nylon involves heating polymer pellets to a molten state, extruding the molten polymer through a spinneret to form fine filaments, and then rapidly cooling the filaments to solidify them. The solidified filaments are drawn or stretched to orient the molecular chains, enhancing tensile strength and elasticity. This process is efficient and widely used for producing synthetic fibers with consistent diameters and mechanical properties.

Process Steps in Solution-Spinning Nylon

Solution-spinning nylon involves dissolving the polymer in a suitable solvent to create a viscous solution, which is then extruded through a spinneret into a coagulation bath where the fibers solidify. This process includes steps such as polymer dissolution, filtration to remove impurities, extrusion through fine holes, and fiber regeneration by solvent removal or coagulation. Compared to melt-spinning, solution-spinning allows for better control of fiber morphology and is particularly useful for nylons with high melting points or sensitive molecular structures.

Comparative Efficiency: Melt-Spinning vs Solution-Spinning

Melt-spinning of nylon offers higher production efficiency due to its faster solidification and lower energy consumption compared to solution-spinning, which involves complex solvent recovery systems and longer processing times. Melt-spinning enables continuous fiber formation directly from molten polymer, resulting in reduced material waste and operational costs, while solution-spinning requires handling toxic solvents and multistep coagulation baths that slow down throughput. Efficiency in melt-spinning supports large-scale nylon fiber manufacturing with consistent quality, making it preferable for industrial textile applications over the more labor-intensive solution-spinning process.

Impact on Fiber Properties and Quality

Melt-spinning of nylon produces fibers with high strength and good dimensional stability due to rapid solidification of the polymer melt, resulting in uniform molecular orientation and crystallinity. Solution-spinning allows for finer control over fiber diameter and enhanced tensile properties by dissolving nylon in solvents, which promotes better molecular alignment and fewer defects. The choice between melt-spinning and solution-spinning directly impacts fiber quality, with solution-spun fibers often exhibiting superior softness and dye affinity but at higher processing costs.

Environmental Considerations of Each Method

Melt-spinning of nylon consumes less water and produces fewer chemical effluents, making it more environmentally friendly compared to solution-spinning, which requires toxic solvents like formic acid that pose disposal challenges. Solution-spinning generates higher energy demands due to solvent recovery processes and risks air pollution from volatile organic compounds (VOCs). Advances in solvent recycling technologies aim to mitigate environmental impacts in solution-spinning, but melt-spinning remains the preferred method for sustainable nylon fiber production.

Cost Implications for Manufacturers

Melt-spinning of nylon involves heating and extruding molten polymer, resulting in a cost-efficient process with lower energy consumption and faster production rates compared to solution-spinning. Solution-spinning requires the dissolution of nylon in solvents, leading to higher raw material and solvent recovery costs, increasing overall production expenses. Manufacturers often prefer melt-spinning for large-scale production due to its reduced operational costs and faster throughput despite solution-spinning's advantage in producing fine and high-performance fibers.

Typical Applications of Each Spinning Technique

Melt-spinning of nylon is typically used to produce fibers for textiles, carpets, and industrial threads due to its cost efficiency and high production speed. Solution-spinning is preferred for specialized applications such as high-strength industrial fibers, medical sutures, and filtration materials because it allows better control over fiber morphology and mechanical properties. Each technique optimizes nylon fiber characteristics to meet specific performance requirements in diverse end-use markets.

Future Trends in Nylon Spinning Technologies

Melt-spinning remains the dominant nylon fiber production method due to its energy efficiency and scalability, while solution-spinning offers superior control over fiber properties for high-performance applications. Emerging trends in nylon spinning technologies focus on hybrid techniques combining melt and solution spinning to enhance fiber strength, elasticity, and environmental sustainability. Advances in bio-based nylon precursors and low-emission spinning processes are driving future innovations to meet growing demands for eco-friendly and high-performance textile materials.

Melt-spinning vs Solution-spinning Infographic

materialdif.com

materialdif.com