High-impact nylon exhibits exceptional toughness and resistance to wear, making it ideal for applications requiring durability under mechanical stress. High-temperature nylon offers superior thermal stability, maintaining strength and performance in elevated heat environments. Choosing between high-impact and high-temperature nylon depends on whether mechanical impact resistance or heat resistance is the primary requirement for the pet product.

Table of Comparison

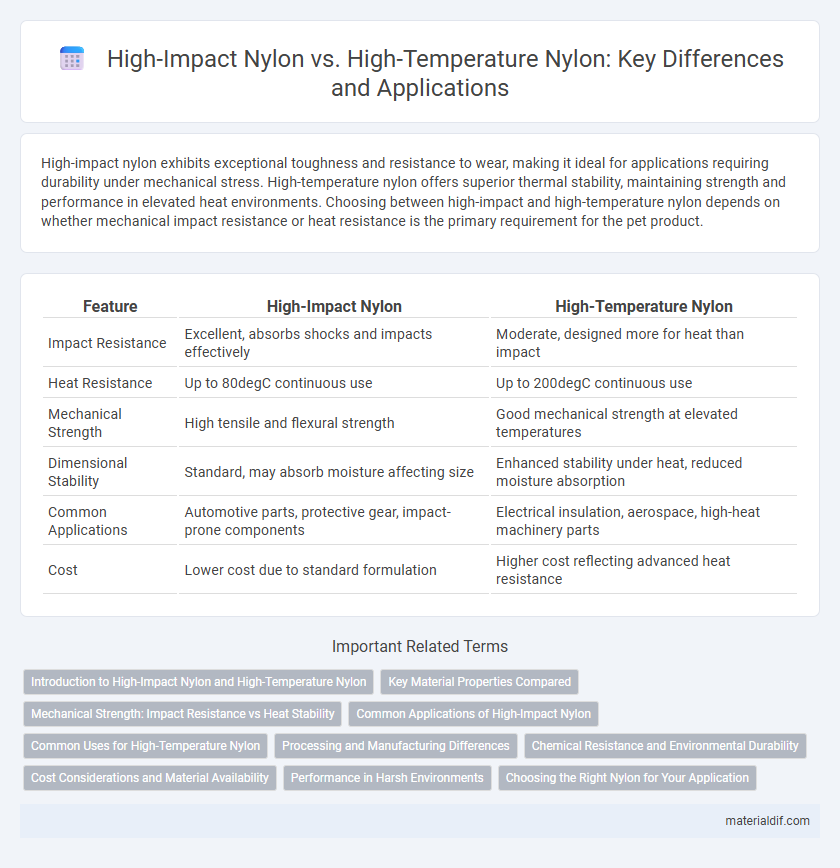

| Feature | High-Impact Nylon | High-Temperature Nylon |

|---|---|---|

| Impact Resistance | Excellent, absorbs shocks and impacts effectively | Moderate, designed more for heat than impact |

| Heat Resistance | Up to 80degC continuous use | Up to 200degC continuous use |

| Mechanical Strength | High tensile and flexural strength | Good mechanical strength at elevated temperatures |

| Dimensional Stability | Standard, may absorb moisture affecting size | Enhanced stability under heat, reduced moisture absorption |

| Common Applications | Automotive parts, protective gear, impact-prone components | Electrical insulation, aerospace, high-heat machinery parts |

| Cost | Lower cost due to standard formulation | Higher cost reflecting advanced heat resistance |

Introduction to High-Impact Nylon and High-Temperature Nylon

High-impact nylon offers superior toughness and impact resistance, making it ideal for applications requiring durability under mechanical stress such as automotive components and protective gear. High-temperature nylon, designed to withstand elevated thermal environments up to 150degC or higher, is commonly used in electrical connectors and under-the-hood automotive parts where heat resistance is critical. Both variants maintain nylon's inherent chemical resistance and dimensional stability, but their specialized formulations cater to distinct industrial performance requirements.

Key Material Properties Compared

High-Impact Nylon exhibits superior toughness and excellent resistance to wear and abrasion, making it ideal for applications requiring durability under mechanical stress. High-Temperature Nylon withstands continuous exposure to elevated temperatures, maintaining dimensional stability and strength beyond 200degC. Both materials offer chemical resistance, but High-Impact Nylon excels in impact absorption while High-Temperature Nylon is optimized for thermal stability and heat resistance.

Mechanical Strength: Impact Resistance vs Heat Stability

High-impact nylon offers superior mechanical strength characterized by excellent impact resistance, making it ideal for applications subjected to sudden shocks and stress. In contrast, high-temperature nylon prioritizes heat stability with the ability to maintain mechanical properties at elevated temperatures up to 180degC, though it typically exhibits lower impact resistance. Choosing between these nylons depends on whether enhanced durability under mechanical shock or sustained performance in high thermal environments is the primary requirement.

Common Applications of High-Impact Nylon

High-impact nylon is extensively used in automotive components, industrial machinery, and consumer goods where durability and resistance to abrasion are critical. This type of nylon excels in applications requiring impact strength, such as gears, bearings, and protective casings. In contrast, high-temperature nylon is favored for electronic housings and engine parts subjected to elevated heat levels, but high-impact nylon dominates in scenarios demanding toughness and mechanical resilience.

Common Uses for High-Temperature Nylon

High-temperature nylon is widely utilized in automotive parts, electrical connectors, and industrial machinery due to its exceptional heat resistance and dimensional stability. This material performs well in environments exceeding 150degC, making it suitable for engine components, electrical insulation, and under-the-hood applications. Its ability to maintain strength and wear resistance under elevated temperatures distinguishes it from high-impact nylon, which excels more in impact resistance and toughness.

Processing and Manufacturing Differences

High-impact nylon is processed with additives such as impact modifiers to enhance toughness and flexibility during injection molding, allowing for improved resistance to mechanical stress in automotive and consumer goods applications. High-temperature nylon undergoes specialized compounding with heat stabilizers and is often processed using techniques like extrusion or injection molding at elevated temperatures, ensuring dimensional stability and strength retention under continuous exposure to temperatures above 150degC. Manufacturing equipment for high-temperature nylon requires advanced thermal controls to prevent degradation, whereas high-impact nylon emphasizes mold design adjustments to optimize impact resistance.

Chemical Resistance and Environmental Durability

High-Impact Nylon offers superior chemical resistance to solvents, oils, and fuels, making it ideal for automotive and industrial components exposed to harsh chemicals. High-Temperature Nylon excels in maintaining structural integrity and environmental durability under elevated thermal conditions, resisting hydrolysis and oxidative degradation in temperatures up to 200degC. Both types demonstrate excellent wear resistance, but High-Temperature Nylon provides enhanced longevity in chemically aggressive, high-heat environments.

Cost Considerations and Material Availability

High-Impact Nylon typically costs less than High-Temperature Nylon due to its more common production processes and widespread availability, making it a cost-effective choice for applications requiring durability without extreme heat resistance. High-Temperature Nylon is priced higher because of specialized formulations that enhance thermal stability, often resulting in limited suppliers and longer lead times. Evaluating project budgets and supply chain flexibility is essential when deciding between these two Nylon types.

Performance in Harsh Environments

High-impact nylon offers exceptional toughness and resistance to mechanical stress, making it ideal for applications involving heavy wear and shock in harsh environments. High-temperature nylon withstands continuous exposure to elevated temperatures up to 210degC, maintaining structural integrity and dimensional stability in extreme thermal conditions. Both variants deliver enhanced durability, but high-impact nylon excels in impact resistance, while high-temperature nylon performs better under thermal strain and chemical exposure.

Choosing the Right Nylon for Your Application

High-impact nylon offers superior toughness and resistance to wear, making it ideal for applications requiring durability under mechanical stress such as automotive parts and industrial gears. High-temperature nylon excels in maintaining structural integrity and performance in elevated thermal environments, suitable for electrical components and engine housings. Selecting the right nylon depends on the specific demands of impact resistance or heat tolerance needed for optimal functionality in your application.

High-Impact Nylon vs High-Temperature Nylon Infographic

materialdif.com

materialdif.com