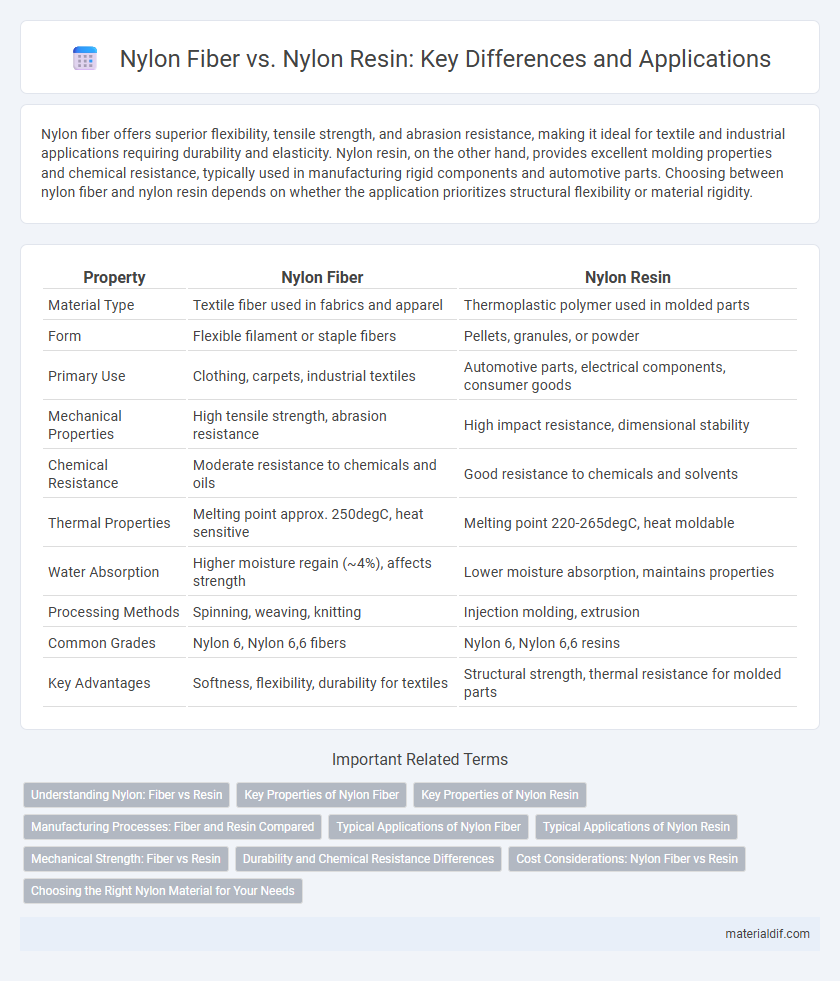

Nylon fiber offers superior flexibility, tensile strength, and abrasion resistance, making it ideal for textile and industrial applications requiring durability and elasticity. Nylon resin, on the other hand, provides excellent molding properties and chemical resistance, typically used in manufacturing rigid components and automotive parts. Choosing between nylon fiber and nylon resin depends on whether the application prioritizes structural flexibility or material rigidity.

Table of Comparison

| Property | Nylon Fiber | Nylon Resin |

|---|---|---|

| Material Type | Textile fiber used in fabrics and apparel | Thermoplastic polymer used in molded parts |

| Form | Flexible filament or staple fibers | Pellets, granules, or powder |

| Primary Use | Clothing, carpets, industrial textiles | Automotive parts, electrical components, consumer goods |

| Mechanical Properties | High tensile strength, abrasion resistance | High impact resistance, dimensional stability |

| Chemical Resistance | Moderate resistance to chemicals and oils | Good resistance to chemicals and solvents |

| Thermal Properties | Melting point approx. 250degC, heat sensitive | Melting point 220-265degC, heat moldable |

| Water Absorption | Higher moisture regain (~4%), affects strength | Lower moisture absorption, maintains properties |

| Processing Methods | Spinning, weaving, knitting | Injection molding, extrusion |

| Common Grades | Nylon 6, Nylon 6,6 fibers | Nylon 6, Nylon 6,6 resins |

| Key Advantages | Softness, flexibility, durability for textiles | Structural strength, thermal resistance for molded parts |

Understanding Nylon: Fiber vs Resin

Nylon fiber, widely used in textiles and apparel, is valued for its strength, elasticity, and abrasion resistance, making it ideal for clothing, carpets, and industrial fabrics. Nylon resin, a raw polymer material, serves as the foundational substance for producing molded plastic parts and engineering components, offering high durability and resistance to chemicals and heat. Understanding the distinction between nylon fiber and nylon resin is crucial for selecting the right form of nylon based on applications in textiles versus manufacturing industries.

Key Properties of Nylon Fiber

Nylon fiber exhibits high tensile strength, excellent abrasion resistance, and superior flexibility, making it ideal for textile and industrial applications. Its moisture-wicking ability and quick-drying properties enhance comfort in apparel, while its thermal resistance ensures durability under varying temperatures. Unlike nylon resin, which is primarily used in molded parts, nylon fiber is engineered for enhanced elasticity and lightweight performance in fabric form.

Key Properties of Nylon Resin

Nylon resin exhibits superior thermal stability, chemical resistance, and mechanical strength compared to nylon fiber, making it ideal for injection molding and engineering applications. Its key properties include high tensile strength, excellent impact resistance, and enhanced dimensional stability under heat. Unlike nylon fibers used in textiles, nylon resin offers rigidity and durability essential for automotive parts, electrical components, and industrial machinery.

Manufacturing Processes: Fiber and Resin Compared

Nylon fiber manufacturing involves melt spinning, where molten nylon resin is extruded through spinnerets and cooled to form continuous filaments, optimized for textile and industrial applications. Nylon resin production starts with the polymerization of monomers like caprolactam, resulting in solid pellets or chips used as raw material for various molding processes. Fiber production emphasizes molecular orientation and drawing techniques to enhance tensile strength and elasticity, while resin manufacturing focuses on polymer chain length and purity to ensure consistent molding quality and mechanical performance.

Typical Applications of Nylon Fiber

Nylon fiber is predominantly used in textile manufacturing for apparel, automotive interiors, and industrial fabrics due to its high strength, elasticity, and abrasion resistance. It finds extensive application in carpets, hosiery, parachutes, and tire cords where durability and flexibility are critical. In contrast, nylon resin is mainly utilized for injection molding and extrusion processes to produce mechanical parts, electrical components, and consumer goods.

Typical Applications of Nylon Resin

Nylon resin is primarily used in injection molding and extrusion processes to produce durable components in automotive parts, electrical connectors, and consumer goods due to its high mechanical strength and chemical resistance. Its versatility allows for applications in gears, bearings, and structural components where thermal stability and wear resistance are critical. Unlike nylon fiber, which is mainly utilized in textiles and fabrics, nylon resin is favored for manufacturing rigid, high-performance plastic parts.

Mechanical Strength: Fiber vs Resin

Nylon fiber exhibits superior mechanical strength compared to nylon resin due to its highly oriented polymer chains, which enhance tensile strength and abrasion resistance in textile applications. Nylon resin, while versatile and durable for molding and manufacturing, generally has lower mechanical strength as its polymer chains are less aligned, resulting in reduced rigidity and impact resistance. This distinction makes nylon fiber preferred for high-stress environments requiring flexibility and toughness, whereas nylon resin suits structural parts needing shape retention and moderate strength.

Durability and Chemical Resistance Differences

Nylon fiber offers excellent tensile strength and flexibility, making it highly durable for textile and industrial applications, whereas nylon resin provides robust structural integrity suited for molded parts. In terms of chemical resistance, nylon resin generally withstands harsher chemical environments better than nylon fiber, thanks to its denser molecular structure. Both materials resist abrasion and impact well, but nylon resin excels in applications requiring higher resistance to solvents and oils.

Cost Considerations: Nylon Fiber vs Resin

Nylon fiber generally incurs higher manufacturing costs due to the complex spinning and texturizing processes compared to nylon resin, which is produced through a more straightforward polymerization and molding procedure. Resin offers cost advantages in large-scale applications requiring injection molding or extrusion, while nylon fiber is preferred despite its price for textiles demanding flexibility and strength. Understanding these cost differences is essential for industries choosing between durability-focused fiber and moldable resin for efficient production budgeting.

Choosing the Right Nylon Material for Your Needs

Nylon fiber offers high tensile strength, elasticity, and abrasion resistance, making it ideal for textiles, ropes, and fishing lines, while nylon resin provides superior moldability and chemical resistance for engineering components and automotive parts. The choice depends on application-specific requirements such as flexibility, durability, thermal stability, and mechanical stress tolerance. Selecting the appropriate nylon material ensures optimal performance, longevity, and cost-effectiveness in manufacturing and end-use applications.

Nylon Fiber vs Nylon Resin Infographic

materialdif.com

materialdif.com