High-impact nylon offers superior durability and resistance to wear compared to standard nylon, making it ideal for demanding applications such as pet collars and leashes. It maintains strength under heavy stress and resists abrasion, ensuring longer-lasting performance. Standard nylon, while lightweight and flexible, may degrade faster under intense use or exposure to outdoor elements.

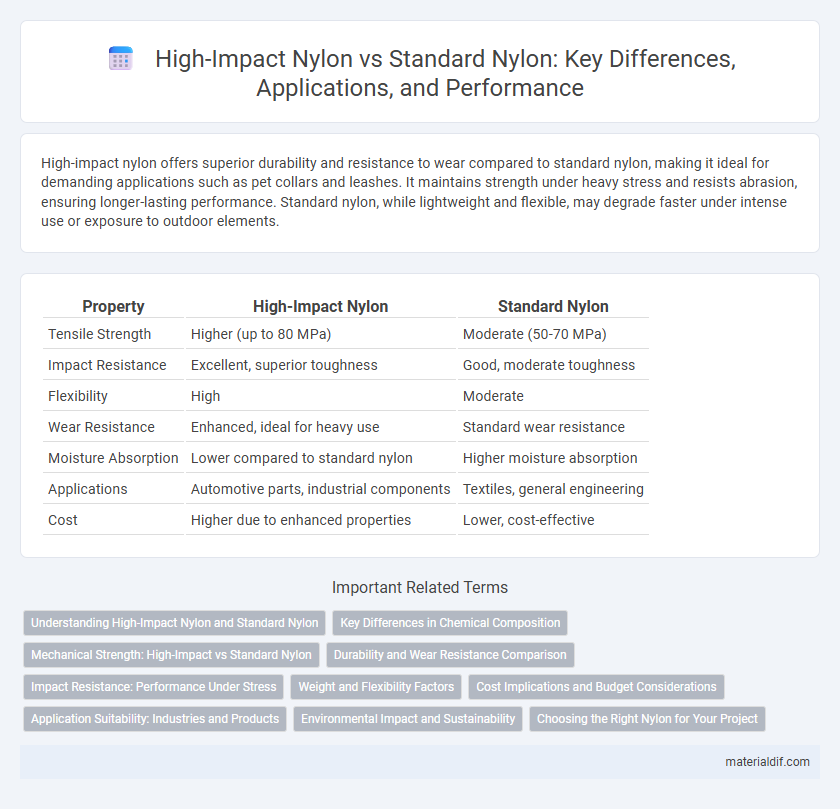

Table of Comparison

| Property | High-Impact Nylon | Standard Nylon |

|---|---|---|

| Tensile Strength | Higher (up to 80 MPa) | Moderate (50-70 MPa) |

| Impact Resistance | Excellent, superior toughness | Good, moderate toughness |

| Flexibility | High | Moderate |

| Wear Resistance | Enhanced, ideal for heavy use | Standard wear resistance |

| Moisture Absorption | Lower compared to standard nylon | Higher moisture absorption |

| Applications | Automotive parts, industrial components | Textiles, general engineering |

| Cost | Higher due to enhanced properties | Lower, cost-effective |

Understanding High-Impact Nylon and Standard Nylon

High-impact nylon features enhanced toughness and improved resistance to cracking compared to standard nylon, making it suitable for applications requiring greater durability and impact strength. Standard nylon, while durable and versatile, offers moderate mechanical properties ideal for everyday use but may not withstand heavy stress or repeated impact as effectively. Understanding these differences helps in selecting the appropriate nylon type for engineering, automotive, or industrial components where performance and longevity are critical.

Key Differences in Chemical Composition

High-impact nylon contains increased amounts of impact modifiers such as rubber particles or elastomers, enhancing its toughness and resistance to cracking compared to standard nylon, which primarily consists of polyamide polymers like Nylon 6 or Nylon 6,6. The chemical structure of high-impact nylon incorporates copolymerization or blending techniques to improve flexibility without compromising stiffness, whereas standard nylon has a more uniform crystalline structure leading to higher rigidity but lower impact resistance. These compositional differences result in distinct mechanical properties ideal for applications requiring enhanced durability and impact absorption.

Mechanical Strength: High-Impact vs Standard Nylon

High-impact nylon exhibits superior mechanical strength compared to standard nylon, offering enhanced toughness and resistance to impact and fatigue. This type of nylon is engineered with modified molecular structures or reinforced additives, resulting in improved tensile strength and durability under high-stress conditions. Standard nylon, while versatile and strong, typically lacks the reinforced resilience required for applications exposed to intense mechanical forces.

Durability and Wear Resistance Comparison

High-Impact Nylon offers superior durability compared to Standard Nylon due to its enhanced polymer structure, which provides greater resistance to cracking and impact stresses. This type of nylon exhibits significantly higher wear resistance, making it ideal for applications subjected to constant friction and mechanical forces. Standard Nylon, while versatile, tends to wear down faster under high-stress conditions, reducing its lifespan in demanding environments.

Impact Resistance: Performance Under Stress

High-impact nylon exhibits superior impact resistance compared to standard nylon, maintaining structural integrity under extreme stress conditions. The enhanced molecular structure in high-impact nylon absorbs and disperses energy more effectively, reducing the risk of cracks and fractures. This performance makes high-impact nylon ideal for demanding applications in automotive parts, industrial machinery, and protective gear where durability under stress is critical.

Weight and Flexibility Factors

High-impact nylon offers superior flexibility and impact resistance compared to standard nylon, making it ideal for applications requiring durability under stress. Despite its enhanced toughness, high-impact nylon typically maintains a comparable weight to standard nylon, ensuring lightweight performance. This balance of weight and flexibility makes high-impact nylon suitable for demanding environments like automotive parts and protective gear.

Cost Implications and Budget Considerations

High-impact nylon typically costs 20-40% more than standard nylon due to enhanced toughness and durability, making it ideal for applications requiring resistance to wear and impact. Budget considerations must weigh the higher initial expenditure against potential savings from reduced maintenance and longer part lifespan. Selecting high-impact nylon can lead to lower total cost of ownership despite the upfront premium.

Application Suitability: Industries and Products

High-impact nylon offers superior toughness and impact resistance compared to standard nylon, making it ideal for automotive parts, industrial machinery, and protective gear that require enhanced durability. Standard nylon, with its balanced strength and flexibility, suits applications in consumer goods, textiles, and light mechanical components where cost-effectiveness and ease of processing are prioritized. The choice between high-impact and standard nylon depends on the specific performance demands of industries such as automotive, aerospace, electronics, and sporting goods.

Environmental Impact and Sustainability

High-impact nylon exhibits enhanced durability and resistance to wear, reducing the frequency of replacement and lowering overall material consumption compared to standard nylon. Its longer lifespan contributes to decreased waste and resource utilization, supporting more sustainable manufacturing practices. However, both types of nylon are derived from petrochemicals, emphasizing the need for recycling initiatives and bio-based alternatives to further mitigate environmental impact.

Choosing the Right Nylon for Your Project

High-impact nylon offers enhanced toughness and resistance to wear, making it ideal for applications involving heavy mechanical stress or frequent abrasion. Standard nylon provides excellent flexibility and chemical resistance, suitable for lighter duty projects or those requiring easier machining. Selecting the right type depends on balancing strength, durability, and project-specific environmental factors for optimal performance.

High-Impact Nylon vs Standard Nylon Infographic

materialdif.com

materialdif.com