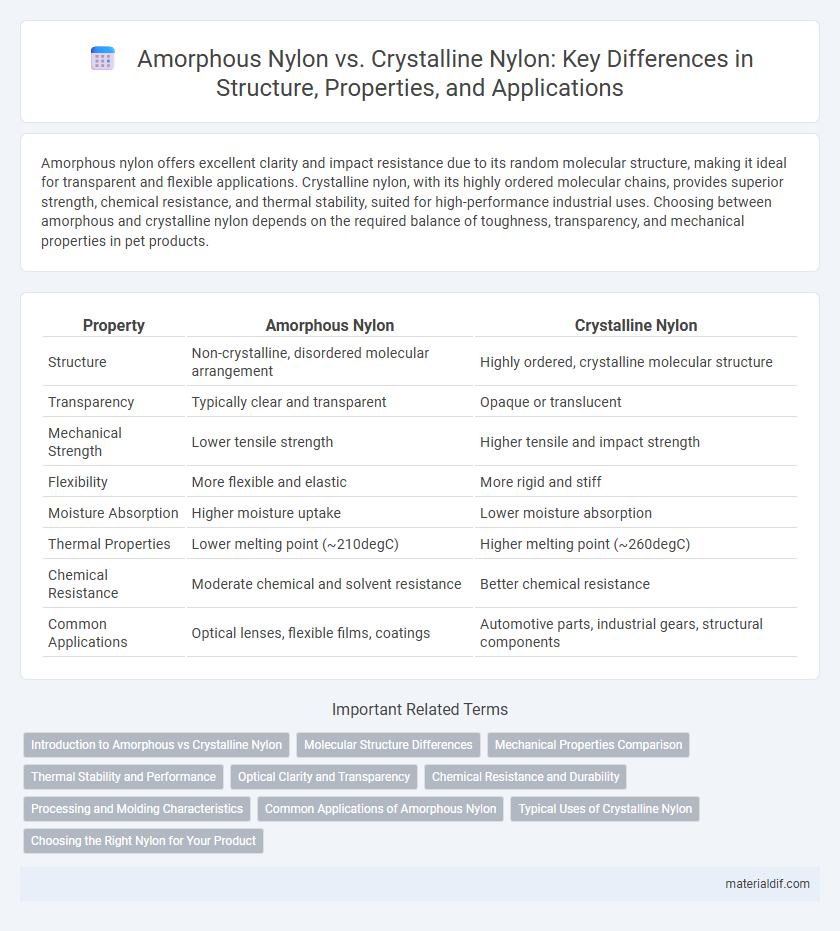

Amorphous nylon offers excellent clarity and impact resistance due to its random molecular structure, making it ideal for transparent and flexible applications. Crystalline nylon, with its highly ordered molecular chains, provides superior strength, chemical resistance, and thermal stability, suited for high-performance industrial uses. Choosing between amorphous and crystalline nylon depends on the required balance of toughness, transparency, and mechanical properties in pet products.

Table of Comparison

| Property | Amorphous Nylon | Crystalline Nylon |

|---|---|---|

| Structure | Non-crystalline, disordered molecular arrangement | Highly ordered, crystalline molecular structure |

| Transparency | Typically clear and transparent | Opaque or translucent |

| Mechanical Strength | Lower tensile strength | Higher tensile and impact strength |

| Flexibility | More flexible and elastic | More rigid and stiff |

| Moisture Absorption | Higher moisture uptake | Lower moisture absorption |

| Thermal Properties | Lower melting point (~210degC) | Higher melting point (~260degC) |

| Chemical Resistance | Moderate chemical and solvent resistance | Better chemical resistance |

| Common Applications | Optical lenses, flexible films, coatings | Automotive parts, industrial gears, structural components |

Introduction to Amorphous vs Crystalline Nylon

Amorphous nylon features a disordered molecular structure, resulting in greater transparency and improved impact resistance, making it ideal for applications requiring flexibility and clarity. Crystalline nylon possesses a highly ordered molecular arrangement, which enhances mechanical strength, chemical resistance, and thermal stability, suitable for demanding engineering components. Understanding these structural differences is crucial for selecting the right nylon type in industries such as automotive, electronics, and consumer goods.

Molecular Structure Differences

Amorphous nylon features a random, irregular molecular arrangement resulting in greater flexibility and transparency but lower density and strength compared to crystalline nylon. Crystalline nylon possesses highly ordered, tightly packed molecular chains that enhance tensile strength, chemical resistance, and thermal stability. The degree of crystallinity directly impacts mechanical properties, with crystalline regions providing rigidity and amorphous zones contributing to elasticity.

Mechanical Properties Comparison

Amorphous nylon exhibits higher impact resistance and better dimensional stability due to its unordered molecular structure, making it more flexible and less brittle under stress. Crystalline nylon, characterized by tightly packed polymer chains, offers superior tensile strength, stiffness, and wear resistance, ideal for applications requiring durability and load-bearing capacity. The balance between toughness and rigidity depends on the degree of crystallinity, influencing performance in engineering and industrial uses.

Thermal Stability and Performance

Amorphous nylon exhibits lower thermal stability due to its disordered molecular structure, making it more susceptible to heat deformation and less suitable for high-temperature applications. Crystalline nylon contains a higher degree of ordered polymer chains, resulting in enhanced thermal resistance, dimensional stability, and mechanical strength at elevated temperatures. Applications requiring sustained performance under thermal stress, such as automotive and industrial components, benefit significantly from crystalline nylon's superior heat tolerance.

Optical Clarity and Transparency

Amorphous nylon exhibits superior optical clarity and transparency compared to crystalline nylon due to its disordered molecular structure, which reduces light scattering. Crystalline nylon contains tightly packed molecular regions that cause opacity and cloudiness by refracting and scattering light. Industries requiring clear, transparent materials, such as optical lenses and medical devices, prefer amorphous nylon for its excellent light transmission properties.

Chemical Resistance and Durability

Amorphous nylon exhibits superior chemical resistance due to its non-crystalline molecular structure, which reduces solvent penetration and degradation. Crystalline nylon offers enhanced durability and mechanical strength, attributed to its highly ordered polymer chains that resist wear and stress. Selecting between amorphous and crystalline nylon depends on balancing chemical resistance requirements with the need for mechanical toughness in specific applications.

Processing and Molding Characteristics

Amorphous nylon exhibits lower crystallinity, resulting in enhanced transparency and easier flow during processing, which is ideal for injection molding applications requiring intricate detail. Crystalline nylon, with higher crystallinity, offers superior mechanical strength and thermal resistance but demands precise temperature control and slower cooling rates to prevent warping during molding. The distinct molecular structures influence cooling behavior and dimensional stability, making amorphous nylon preferred for complex geometries and crystalline nylon suited for high-performance mechanical parts.

Common Applications of Amorphous Nylon

Amorphous nylon is widely used in applications requiring high impact resistance and excellent dimensional stability, such as automotive parts, electrical connectors, and consumer electronics housings. Its non-crystalline structure provides better transparency and flexibility compared to crystalline nylon, making it suitable for optical components and flexible films. The material's superior chemical resistance and toughness extend its use to medical devices and industrial components exposed to harsh environments.

Typical Uses of Crystalline Nylon

Crystalline nylon is widely used in automotive parts, electrical components, and industrial machinery due to its high strength, excellent abrasion resistance, and superior chemical stability. Its semi-crystalline structure enhances dimensional stability and mechanical performance, making it ideal for gears, bearings, and structural components subjected to mechanical stress. Applications also include consumer goods and sports equipment where durability and resistance to fatigue are critical.

Choosing the Right Nylon for Your Product

Selecting the right nylon for your product depends on understanding the distinct properties of amorphous and crystalline nylon variants. Amorphous nylon offers superior transparency, flexibility, and impact resistance, ideal for applications requiring optical clarity and toughness. Crystalline nylon provides higher chemical resistance, mechanical strength, and thermal stability, making it suitable for components exposed to harsh environments and elevated temperatures.

Amorphous Nylon vs Crystalline Nylon Infographic

materialdif.com

materialdif.com