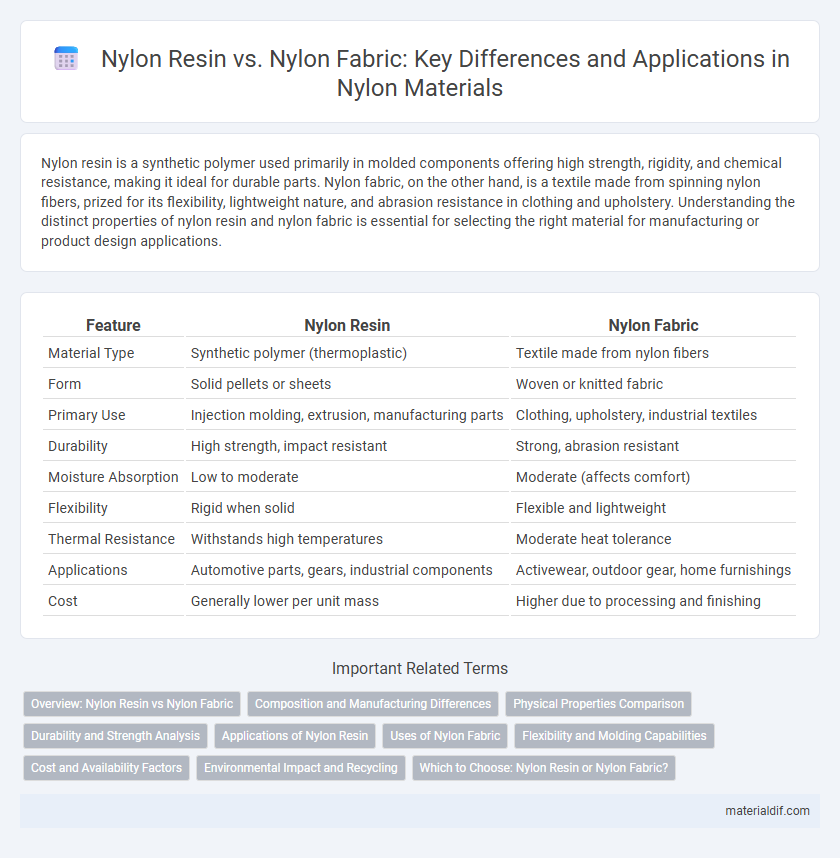

Nylon resin is a synthetic polymer used primarily in molded components offering high strength, rigidity, and chemical resistance, making it ideal for durable parts. Nylon fabric, on the other hand, is a textile made from spinning nylon fibers, prized for its flexibility, lightweight nature, and abrasion resistance in clothing and upholstery. Understanding the distinct properties of nylon resin and nylon fabric is essential for selecting the right material for manufacturing or product design applications.

Table of Comparison

| Feature | Nylon Resin | Nylon Fabric |

|---|---|---|

| Material Type | Synthetic polymer (thermoplastic) | Textile made from nylon fibers |

| Form | Solid pellets or sheets | Woven or knitted fabric |

| Primary Use | Injection molding, extrusion, manufacturing parts | Clothing, upholstery, industrial textiles |

| Durability | High strength, impact resistant | Strong, abrasion resistant |

| Moisture Absorption | Low to moderate | Moderate (affects comfort) |

| Flexibility | Rigid when solid | Flexible and lightweight |

| Thermal Resistance | Withstands high temperatures | Moderate heat tolerance |

| Applications | Automotive parts, gears, industrial components | Activewear, outdoor gear, home furnishings |

| Cost | Generally lower per unit mass | Higher due to processing and finishing |

Overview: Nylon Resin vs Nylon Fabric

Nylon resin is a synthetic polymer used primarily in injection molding and extrusion processes to create durable plastic components with high tensile strength and chemical resistance. Nylon fabric, made from spun nylon fibers, offers lightweight, abrasion-resistant textiles widely used in apparel and industrial applications. While nylon resin emphasizes structural and mechanical properties for manufacturing, nylon fabric focuses on flexibility, breathability, and comfort in textile products.

Composition and Manufacturing Differences

Nylon resin consists of polymerized synthetic polyamides formed through condensation reactions between diamines and dicarboxylic acids, primarily used as a raw material for molding plastics and engineering components. Nylon fabric is produced by spinning nylon resin into fibers through melt spinning or solution spinning processes, which are then woven or knitted into textiles. The key composition difference is that resin is a solid polymer pellet, whereas fabric is a flexible textile form created by aligning and bonding nylon fibers.

Physical Properties Comparison

Nylon resin exhibits high tensile strength, excellent abrasion resistance, and superior impact toughness, making it ideal for injection molding and engineering components. Nylon fabric, woven from nylon fibers, offers flexibility, lightweight durability, and moisture-wicking properties, commonly used in textiles and apparel. The resin's rigid structure contrasts with the fabric's pliable nature, influencing their respective applications in industrial manufacturing versus garment production.

Durability and Strength Analysis

Nylon resin exhibits superior tensile strength and impact resistance compared to nylon fabric, making it ideal for heavy-duty industrial applications and molded components. Nylon fabric, while flexible and lightweight, offers excellent abrasion resistance and durability in textile uses but lacks the rigidity and load-bearing capacity of nylon resin. Both materials benefit from nylon's inherent toughness, yet resin is preferred when structural integrity and long-term durability under stress are critical.

Applications of Nylon Resin

Nylon resin is widely used in industrial applications such as automotive parts, electrical components, and mechanical gears due to its high strength, durability, and resistance to abrasion and chemicals. Unlike nylon fabric, which is primarily used in textiles and apparel for its flexibility and comfort, nylon resin provides structural integrity and thermal stability in manufacturing processes. Its excellent moldability and impact resistance make it a preferred material for producing precision-engineered parts and consumer goods.

Uses of Nylon Fabric

Nylon fabric is widely used in apparel, including activewear, hosiery, and lingerie, due to its elasticity, durability, and moisture-wicking properties. It is also a preferred material for outdoor gear such as tents, backpacks, and parachutes because of its high tensile strength and resistance to abrasion. In contrast, nylon resin primarily serves as a raw material in manufacturing molded components for automotive parts, electrical housings, and industrial machinery.

Flexibility and Molding Capabilities

Nylon resin offers superior molding capabilities due to its thermoplastic properties, allowing it to be shaped into complex, precise forms through injection molding and extrusion processes. Nylon fabric, derived from spun nylon fibers, provides excellent flexibility and stretch, making it ideal for applications requiring durability and comfort such as clothing and upholstery. While nylon resin excels in structural and mechanical applications, nylon fabric is preferred for flexible, wearable, and textile products.

Cost and Availability Factors

Nylon resin is a raw polymer material primarily used for manufacturing plastic components, typically available at lower costs due to bulk production and industrial-scale supply chains. Nylon fabric, made from spun nylon fibers, generally incurs higher costs because of additional processing, weaving, and finishing steps required to transform resin into textile form. Availability of nylon resin is more consistent and widespread in manufacturing sectors, while nylon fabric availability can vary based on market demand, textile industry capacity, and regional production capabilities.

Environmental Impact and Recycling

Nylon resin, a thermoplastic polymer, is primarily used in manufacturing plastic components and has a higher potential for recycling through melting and remolding processes, reducing waste in industrial applications. In contrast, nylon fabric, commonly used in textiles and apparel, presents more complex recycling challenges due to blends with other fibers and contamination from dyes and treatments. Both forms of nylon contribute to microplastic pollution, but advancements in chemical recycling technologies offer promising solutions for improving environmental sustainability in both nylon resin and fabric industries.

Which to Choose: Nylon Resin or Nylon Fabric?

Nylon resin offers superior strength, chemical resistance, and thermal stability, making it ideal for molding durable components in automotive and industrial applications. Nylon fabric provides flexibility, breathability, and abrasion resistance, preferred for apparel, upholstery, and outdoor gear that require comfort and wearability. Choosing between nylon resin and nylon fabric depends on whether the priority lies in structural performance or textile functionality.

Nylon Resin vs Nylon Fabric Infographic

materialdif.com

materialdif.com