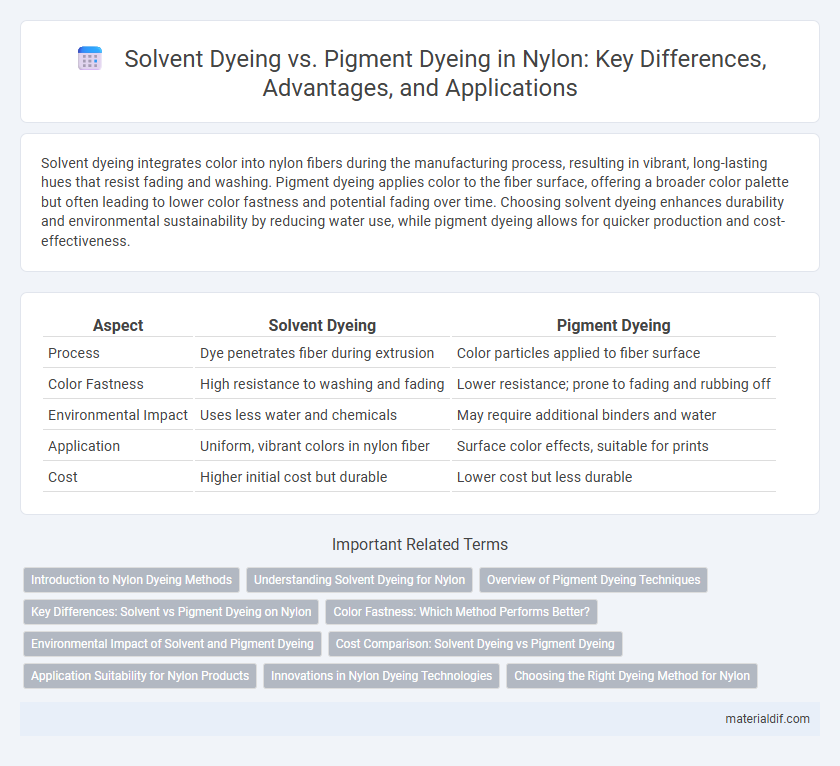

Solvent dyeing integrates color into nylon fibers during the manufacturing process, resulting in vibrant, long-lasting hues that resist fading and washing. Pigment dyeing applies color to the fiber surface, offering a broader color palette but often leading to lower color fastness and potential fading over time. Choosing solvent dyeing enhances durability and environmental sustainability by reducing water use, while pigment dyeing allows for quicker production and cost-effectiveness.

Table of Comparison

| Aspect | Solvent Dyeing | Pigment Dyeing |

|---|---|---|

| Process | Dye penetrates fiber during extrusion | Color particles applied to fiber surface |

| Color Fastness | High resistance to washing and fading | Lower resistance; prone to fading and rubbing off |

| Environmental Impact | Uses less water and chemicals | May require additional binders and water |

| Application | Uniform, vibrant colors in nylon fiber | Surface color effects, suitable for prints |

| Cost | Higher initial cost but durable | Lower cost but less durable |

Introduction to Nylon Dyeing Methods

Nylon dyeing methods primarily include solvent dyeing and pigment dyeing, each offering distinct advantages in textile applications. Solvent dyeing involves incorporating colorants directly into the polymer solution, resulting in vibrant, long-lasting hues with excellent colorfastness. Pigment dyeing, on the other hand, applies insoluble color particles onto the fiber surface, providing versatile coloration but often requiring binders to ensure durability and washfastness.

Understanding Solvent Dyeing for Nylon

Solvent dyeing for nylon involves dissolving dye directly into the polymer solution before fiber formation, resulting in deep, vibrant colors with excellent colorfastness and resistance to fading. This method ensures uniform coloration throughout the fiber, enhances durability, and reduces water and chemical usage compared to conventional surface dyeing techniques. Solvent dyeing is particularly advantageous for producing high-performance nylon textiles used in automotive, sportswear, and outdoor gear applications.

Overview of Pigment Dyeing Techniques

Pigment dyeing techniques for nylon involve applying colored pigments directly onto the fabric surface, creating vibrant hues with excellent colorfastness and resistance to fading. This method utilizes binders to fix pigments onto the fiber, ensuring durability and uniform coverage without penetrating the fiber deeply. Pigment dyeing is favored for its versatility in producing a wide range of colors and effects, especially on nylon textiles used in fashion and industrial applications.

Key Differences: Solvent vs Pigment Dyeing on Nylon

Solvent dyeing involves the incorporation of dye molecules directly into the nylon polymer solution before fiber extrusion, resulting in superior colorfastness, vibrancy, and resistance to fading compared to pigment dyeing. Pigment dyeing applies insoluble color particles on the fabric surface, which adhere loosely and often require binders, leading to lower wash durability and less uniform coloration on nylon textiles. The deep penetration of solvent dyes into the nylon fiber enhances overall fabric performance, while pigment dyeing offers cost-effectiveness but sacrifices long-term color retention and fabric hand feel.

Color Fastness: Which Method Performs Better?

Solvent dyeing offers superior color fastness for nylon fabrics due to its process of infusing dye molecules into the fiber, resulting in vibrant, long-lasting colors resistant to fading from washing, sunlight, and abrasion. Pigment dyeing, which involves applying color particles on the fabric's surface, generally exhibits lower durability and color retention, making it more prone to fading and wear over time. For applications demanding high performance and sustained color integrity, solvent-dyed nylon is the preferred choice.

Environmental Impact of Solvent and Pigment Dyeing

Solvent dyeing of nylon minimizes water consumption and generates less wastewater compared to pigment dyeing, which often requires significant water and chemical use in the dyeing and finishing processes. Pigment dyeing involves binding pigments to the fiber surface, leading to heavier reliance on binders and resins that can increase environmental toxicity and reduce fabric recyclability. Solvent dyeing offers a more sustainable alternative by reducing chemical discharge and energy use throughout the production cycle.

Cost Comparison: Solvent Dyeing vs Pigment Dyeing

Solvent dyeing for nylon typically incurs higher initial costs due to specialized machinery and solvent recovery systems, but it offers superior colorfastness and less environmental waste. Pigment dyeing presents lower upfront expenses, relying on simple application methods and broad compatibility with different fabric types, though it may lead to increased water usage and additional post-treatment costs. Evaluating total cost-effectiveness, solvent dyeing often proves more economical over time, especially for high-volume nylon production requiring durable, vibrant colors.

Application Suitability for Nylon Products

Solvent dyeing offers superior colorfastness and is ideal for nylon products exposed to outdoor conditions and frequent washing, such as activewear and outdoor gear. Pigment dyeing provides diverse color options and cost-effective solutions, making it suitable for fashion-oriented nylon items where vibrant colors and design flexibility are prioritized. Nylon products requiring high durability and color retention benefit most from solvent dyeing, while those focused on aesthetics and budget efficiency often utilize pigment dyeing techniques.

Innovations in Nylon Dyeing Technologies

Innovations in nylon dyeing technologies have led to significant advancements in solvent dyeing and pigment dyeing methods, enhancing color fastness and environmental sustainability. Solvent dyeing techniques now use eco-friendly solvents that reduce water consumption and emissions, while pigment dyeing innovations involve nano-pigment encapsulation for improved adhesion and vibrancy on nylon fibers. These technological breakthroughs optimize dye uptake, minimize resource usage, and extend the lifecycle of nylon textiles in fashion and industrial applications.

Choosing the Right Dyeing Method for Nylon

Solvent dyeing offers superior colorfastness and vibrant hues for nylon fabrics, making it ideal for performance wear and outdoor applications. Pigment dyeing provides cost-effective color options with unique faded effects but may lack durability and wash fastness on nylon fibers. Selecting the right dyeing method depends on balancing desired aesthetic outcomes with functional requirements such as resistance to fading and abrasion.

Solvent Dyeing vs Pigment Dyeing Infographic

materialdif.com

materialdif.com