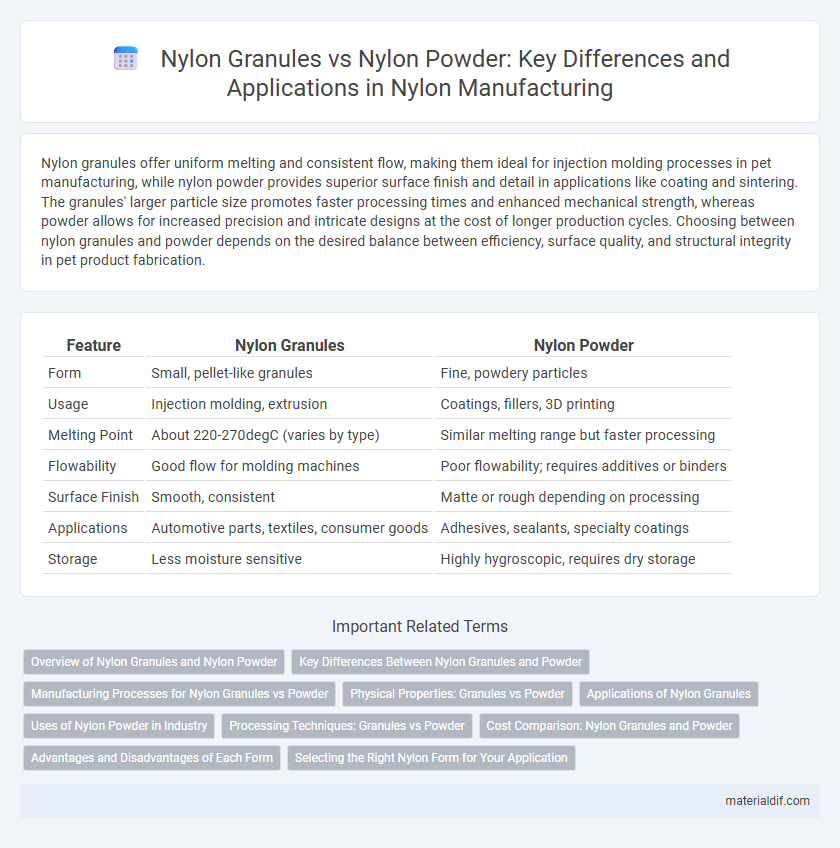

Nylon granules offer uniform melting and consistent flow, making them ideal for injection molding processes in pet manufacturing, while nylon powder provides superior surface finish and detail in applications like coating and sintering. The granules' larger particle size promotes faster processing times and enhanced mechanical strength, whereas powder allows for increased precision and intricate designs at the cost of longer production cycles. Choosing between nylon granules and powder depends on the desired balance between efficiency, surface quality, and structural integrity in pet product fabrication.

Table of Comparison

| Feature | Nylon Granules | Nylon Powder |

|---|---|---|

| Form | Small, pellet-like granules | Fine, powdery particles |

| Usage | Injection molding, extrusion | Coatings, fillers, 3D printing |

| Melting Point | About 220-270degC (varies by type) | Similar melting range but faster processing |

| Flowability | Good flow for molding machines | Poor flowability; requires additives or binders |

| Surface Finish | Smooth, consistent | Matte or rough depending on processing |

| Applications | Automotive parts, textiles, consumer goods | Adhesives, sealants, specialty coatings |

| Storage | Less moisture sensitive | Highly hygroscopic, requires dry storage |

Overview of Nylon Granules and Nylon Powder

Nylon granules are small, uniform pellets commonly used in injection molding and extrusion processes due to their consistent melt flow and high mechanical strength. Nylon powder features finer particle sizes ideal for selective laser sintering and coating applications, providing excellent surface finish and enhanced detail resolution. Both forms offer distinct advantages in manufacturing, with granules suited for bulk processing and powders optimized for precision and additive manufacturing techniques.

Key Differences Between Nylon Granules and Powder

Nylon granules and nylon powder differ primarily in particle size and application methods; granules are larger, facilitating easier handling and melting for injection molding, while powder's fine particles enable precision in coatings and selective laser sintering (SLS) 3D printing. Granules offer superior flow properties and uniform melting, making them ideal for extrusion and molding, whereas powder provides higher surface area for better sintering and coating adhesion. Understanding these distinctions is critical for optimizing manufacturing processes and achieving desired mechanical properties in nylon-based products.

Manufacturing Processes for Nylon Granules vs Powder

Nylon granules are produced through melt extrusion where raw nylon polymer is melted, extruded, and pelletized into small uniform beads, facilitating easy handling and consistent melting during injection molding. Nylon powder manufacturing typically involves spray drying or cryogenic grinding of nylon flake, resulting in fine particles ideal for selective laser sintering and other powder-based additive manufacturing techniques. Granule production emphasizes uniformity and flowability for melting processes, while powder production prioritizes particle size distribution and surface area for enhanced sintering performance.

Physical Properties: Granules vs Powder

Nylon granules exhibit higher density and improved flowability compared to nylon powder, which tends to have lower bulk density and increased surface area, affecting processing behavior. Granules offer uniform melting and enhanced mechanical strength due to their consistent particle size, while powders provide better compaction but may lead to agglomeration and less predictable thermal properties. The choice between nylon granules and powder impacts molding precision, surface finish, and overall material performance in manufacturing applications.

Applications of Nylon Granules

Nylon granules are widely used in injection molding and extrusion processes for manufacturing automotive parts, electrical components, and consumer goods due to their superior flow properties and consistent melting behavior. Their granular form enables precise control over melting and molding, making them ideal for high-strength, durable applications requiring complex shapes. In contrast, nylon powder is primarily utilized in sintering and coating applications where fine particle size offers better surface finish and porosity control.

Uses of Nylon Powder in Industry

Nylon powder is extensively used in industries for applications such as 3D printing, sintering, and coating processes due to its fine particle size and superior flow properties. It offers enhanced surface finish and mechanical strength in additive manufacturing, making it ideal for producing complex, high-precision parts in automotive and aerospace sectors. Compared to nylon granules, nylon powder enables more efficient and versatile manufacturing techniques, especially in prototyping and small-batch production.

Processing Techniques: Granules vs Powder

Nylon granules are favored in injection molding and extrusion processes due to their uniform size and consistent melting behavior, providing reliable flow and minimal defects. Nylon powder, used primarily in selective laser sintering (SLS) and 3D printing, enables precise layer-by-layer fabrication but requires careful control of particle size and thermal properties for optimal fusion. Processing techniques for nylon must consider granule uniformity in melting versus powder's surface area and sintering characteristics to achieve desired mechanical performance.

Cost Comparison: Nylon Granules and Powder

Nylon granules typically cost more per unit weight than nylon powder due to their processing advantages and ease of handling in manufacturing. Nylon powder, while cheaper initially, may incur additional costs during sintering or molding processes because of its finer particle size and need for precise temperature control. The total production cost depends on the specific application and equipment, with granules favored for injection molding and powders preferred for selective laser sintering in 3D printing.

Advantages and Disadvantages of Each Form

Nylon granules offer consistent melting behavior and ease of processing, making them ideal for injection molding and extrusion with minimal waste. Nylon powder enables fine detail in selective laser sintering and 3D printing but requires precise temperature control to avoid agglomeration and uneven melting. While granules provide superior mechanical strength and flow properties, powders allow for complex geometries and smoother surface finishes in finished parts.

Selecting the Right Nylon Form for Your Application

Nylon granules offer superior flow characteristics and are ideal for injection molding and extrusion processes requiring uniform melting and consistent quality. Nylon powder provides enhanced surface finish and is preferred in applications like selective laser sintering (SLS) 3D printing, where fine detail and precise layering are crucial. Selecting the right form depends on factors such as processing technique, desired mechanical properties, and final product application.

Nylon Granules vs Nylon Powder Infographic

materialdif.com

materialdif.com