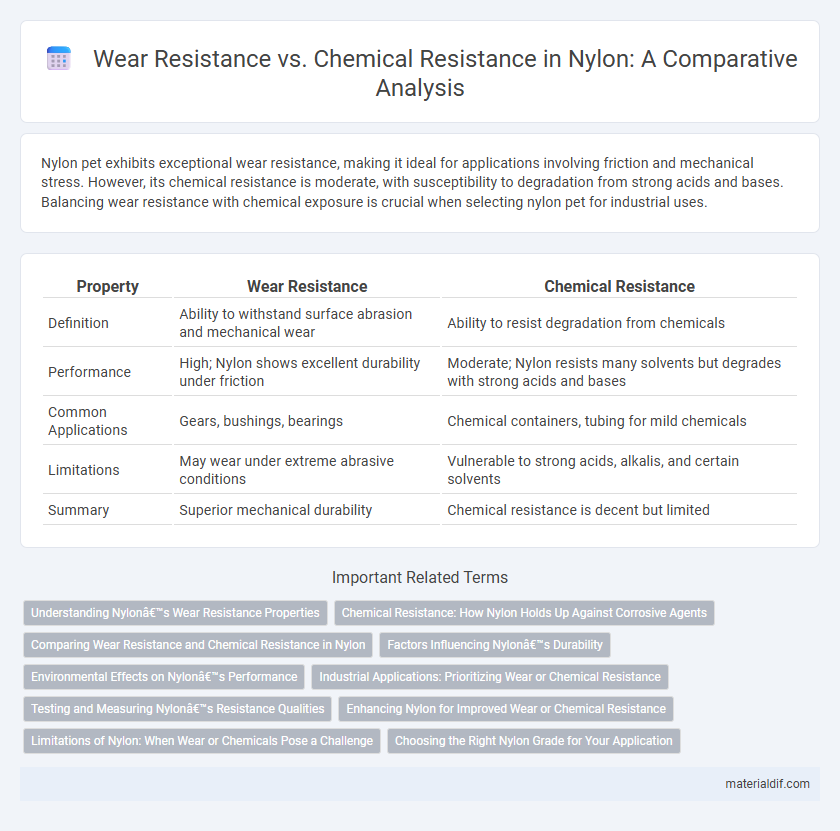

Nylon pet exhibits exceptional wear resistance, making it ideal for applications involving friction and mechanical stress. However, its chemical resistance is moderate, with susceptibility to degradation from strong acids and bases. Balancing wear resistance with chemical exposure is crucial when selecting nylon pet for industrial uses.

Table of Comparison

| Property | Wear Resistance | Chemical Resistance |

|---|---|---|

| Definition | Ability to withstand surface abrasion and mechanical wear | Ability to resist degradation from chemicals |

| Performance | High; Nylon shows excellent durability under friction | Moderate; Nylon resists many solvents but degrades with strong acids and bases |

| Common Applications | Gears, bushings, bearings | Chemical containers, tubing for mild chemicals |

| Limitations | May wear under extreme abrasive conditions | Vulnerable to strong acids, alkalis, and certain solvents |

| Summary | Superior mechanical durability | Chemical resistance is decent but limited |

Understanding Nylon’s Wear Resistance Properties

Nylon exhibits excellent wear resistance due to its high tensile strength and abrasion resistance, making it ideal for applications involving friction and mechanical stress. Its molecular structure provides durability against physical wear but shows lower resistance to certain chemicals like strong acids and bases, which can degrade its mechanical properties. Understanding this balance is crucial for selecting nylon in environments where both mechanical wear and chemical exposure occur.

Chemical Resistance: How Nylon Holds Up Against Corrosive Agents

Nylon exhibits moderate chemical resistance, maintaining integrity when exposed to oils, greases, and some solvents but can degrade when in contact with strong acids or bases. Its molecular structure allows resistance to hydrocarbons and alkalis, making it suitable for industrial applications involving mild corrosive agents. However, prolonged exposure to harsh chemicals like concentrated acids leads to weakening and loss of mechanical properties, underscoring the need for careful material selection in aggressive chemical environments.

Comparing Wear Resistance and Chemical Resistance in Nylon

Nylon exhibits high wear resistance due to its strong molecular structure and excellent abrasion tolerance, making it ideal for applications involving friction and mechanical stress. However, its chemical resistance is moderate, as exposure to strong acids, bases, and certain solvents can degrade the polymer over time. Comparing both properties, nylon is preferred in environments requiring durability against physical wear but requires protective coatings or additives for enhanced chemical resistance in aggressive chemical settings.

Factors Influencing Nylon’s Durability

Nylon's durability is significantly influenced by its wear resistance, which depends on factors such as fiber density, surface hardness, and frictional properties that reduce abrasion. Chemical resistance is affected by nylon's molecular structure and exposure to acids, alkalis, and solvents, which can degrade its polymer chains over time. Environmental conditions, including temperature and moisture absorption, also play a critical role in balancing wear resistance and chemical resistance for optimal nylon performance.

Environmental Effects on Nylon’s Performance

Nylon exhibits high wear resistance, making it ideal for applications involving friction and mechanical stress, but its chemical resistance varies with environmental exposure, particularly to acids, bases, and moisture. Prolonged exposure to humid or acidic conditions can cause nylon to absorb water, leading to reduced mechanical strength and increased dimensional changes, which compromises its wear resistance. Understanding the balance between wear resistance and chemical resistance is crucial for optimizing nylon's performance in environments subject to chemical corrosion and mechanical wear.

Industrial Applications: Prioritizing Wear or Chemical Resistance

Nylon's wear resistance makes it ideal for industrial applications involving friction and mechanical stress, such as gears, bearings, and conveyor belts, where durability is critical to minimize downtime. Chemical resistance is crucial in environments with exposure to oils, solvents, or acids, where standard nylon may degrade unless specially formulated or coated. Selecting nylon grades with enhanced wear properties prioritizes longevity under physical abrasion, while chemically resistant variants ensure performance and stability in corrosive industrial conditions.

Testing and Measuring Nylon’s Resistance Qualities

Wear resistance and chemical resistance of nylon are evaluated using standardized tests such as ASTM D4060 for abrasion and ASTM D543 for chemical exposure. Test methods involve measuring weight loss, surface degradation, and tensile strength after prolonged exposure to specific chemicals or mechanical stress. These quantifiable results provide critical data to optimize nylon formulations for durable, application-specific performance.

Enhancing Nylon for Improved Wear or Chemical Resistance

Enhancing nylon for improved wear resistance involves incorporating additives like carbon fibers or aramid to boost abrasion durability, making it ideal for high-friction applications such as gears and bearings. To increase chemical resistance, nylon can be modified with blends or coatings that protect against hydrocarbons, acids, and solvents commonly encountered in industrial environments. Advanced compounding techniques balance wear and chemical resistance, optimizing nylon's performance for demanding mechanical and chemical exposure conditions.

Limitations of Nylon: When Wear or Chemicals Pose a Challenge

Nylon excels in wear resistance, making it suitable for applications involving friction and mechanical stress; however, its chemical resistance is limited, especially against strong acids, alkalis, and certain solvents that can degrade its structure. Prolonged exposure to harsh chemicals can cause nylon to swell, weaken, or lose dimensional stability, restricting its use in aggressive chemical environments. Wear resistance diminishes significantly when chemical degradation occurs, highlighting nylon's limitations in settings where both high abrasion and chemical exposure are present.

Choosing the Right Nylon Grade for Your Application

Selecting the right nylon grade hinges on balancing wear resistance and chemical resistance according to application demands. Nylon 6/6 offers superior wear resistance for mechanical parts exposed to friction, while Nylon 6 exhibits enhanced chemical resistance suitable for exposure to solvents and oils. Consider operating conditions such as temperature, load, and chemical exposure to optimize performance and durability in your specific use case.

Wear Resistance vs Chemical Resistance Infographic

materialdif.com

materialdif.com