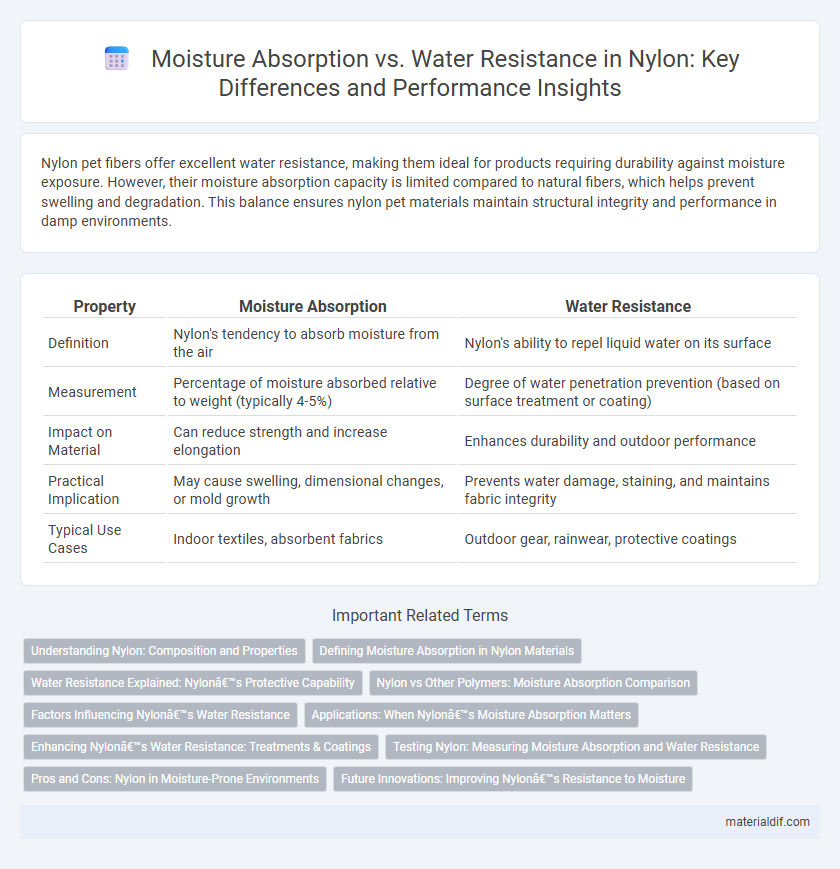

Nylon pet fibers offer excellent water resistance, making them ideal for products requiring durability against moisture exposure. However, their moisture absorption capacity is limited compared to natural fibers, which helps prevent swelling and degradation. This balance ensures nylon pet materials maintain structural integrity and performance in damp environments.

Table of Comparison

| Property | Moisture Absorption | Water Resistance |

|---|---|---|

| Definition | Nylon's tendency to absorb moisture from the air | Nylon's ability to repel liquid water on its surface |

| Measurement | Percentage of moisture absorbed relative to weight (typically 4-5%) | Degree of water penetration prevention (based on surface treatment or coating) |

| Impact on Material | Can reduce strength and increase elongation | Enhances durability and outdoor performance |

| Practical Implication | May cause swelling, dimensional changes, or mold growth | Prevents water damage, staining, and maintains fabric integrity |

| Typical Use Cases | Indoor textiles, absorbent fabrics | Outdoor gear, rainwear, protective coatings |

Understanding Nylon: Composition and Properties

Nylon's semi-crystalline polymer structure contributes to moderate moisture absorption, typically around 4% under standard conditions, which affects its dimensional stability and mechanical strength. Despite this, nylon exhibits excellent water resistance due to its hydrophobic molecular chains and tight polymer packing, making it suitable for applications requiring durability in wet environments. Understanding nylon's balance of moisture absorption and water resistance is crucial for optimizing its performance in textiles, automotive components, and industrial parts.

Defining Moisture Absorption in Nylon Materials

Moisture absorption in nylon materials refers to the capacity of nylon fibers to absorb and retain water molecules from the surrounding environment, impacting their physical and mechanical properties. Nylon typically absorbs around 2-4% moisture at standard atmospheric conditions, leading to changes in tensile strength, flexibility, and dimensional stability. This hygroscopic nature contrasts with its water resistance, where treated or coated nylons exhibit reduced water penetration, enhancing durability in wet conditions.

Water Resistance Explained: Nylon’s Protective Capability

Nylon exhibits moderate water resistance due to its hydrophobic polymer chains, which repel water molecules and limit moisture penetration. This synthetic fiber's tightly woven structure enhances its ability to prevent liquid absorption, making it suitable for applications requiring lightweight moisture barriers. Its water resistance supports durability and quick-drying characteristics, distinguishing nylon from highly absorbent natural fibers.

Nylon vs Other Polymers: Moisture Absorption Comparison

Nylon exhibits higher moisture absorption compared to many other polymers such as polyethylene and polypropylene, typically absorbing up to 4% of its weight in water. This increased moisture uptake results from its polar amide groups, which attract and bond with water molecules, impacting mechanical properties and dimensional stability. In contrast, non-polar polymers with low moisture absorption maintain better water resistance, making them suitable for applications requiring minimal moisture interaction.

Factors Influencing Nylon’s Water Resistance

Nylon's water resistance is influenced by its molecular structure, which includes tightly packed polymer chains that limit water penetration while allowing some moisture absorption due to its hydrophilic amide groups. Environmental factors such as temperature, humidity, and exposure time affect nylon's water resistance performance, with higher humidity increasing moisture absorption rates. Treatments like coatings or chemical modifications can significantly enhance nylon's water resistance by creating a barrier that reduces water permeability without compromising the fabric's strength or flexibility.

Applications: When Nylon’s Moisture Absorption Matters

Nylon's moderate moisture absorption, ranging from 2% to 4%, influences its suitability in applications like activewear, outdoor gear, and automotive components where breathability and flexibility are crucial. This hygroscopic nature can impact dimensional stability and mechanical properties, making water-resistant treatments essential for performance in wet environments. Understanding Nylon's moisture absorption guides material selection in industries prioritizing durability and comfort under varying humidity conditions.

Enhancing Nylon’s Water Resistance: Treatments & Coatings

Nylon's inherent moisture absorption can be significantly reduced through advanced water-resistant treatments and specialized coatings, such as silicone-based or fluoropolymer finishes. These innovations create a protective barrier that repels water while maintaining nylon's flexibility and strength. Enhanced water resistance extends nylon's durability and usability in high-performance applications like outdoor gear and technical textiles.

Testing Nylon: Measuring Moisture Absorption and Water Resistance

Testing nylon involves precise measurement of moisture absorption by evaluating the percentage of water uptake under controlled humidity and temperature conditions, typically using gravimetric analysis. Water resistance is assessed through hydrostatic pressure tests and water repellency ratings, determining nylon's ability to prevent water penetration. Accurate testing ensures nylon fabrics meet performance standards in applications requiring durability and moisture management.

Pros and Cons: Nylon in Moisture-Prone Environments

Nylon exhibits moderate moisture absorption, which can lead to reduced tensile strength and dimensional changes in high-humidity environments, posing challenges for long-term durability. Its water resistance, while notable due to its hydrophobic molecular structure, is limited without additional coatings or treatments, making it less suitable for prolonged exposure to wet conditions. Nylon's balance between moisture absorption and water resistance requires careful consideration in moisture-prone applications to ensure optimal performance and longevity.

Future Innovations: Improving Nylon’s Resistance to Moisture

Future innovations in nylon technology aim to enhance moisture resistance by developing advanced polymer blends and surface treatments that minimize water absorption. Researchers are integrating hydrophobic nanocoatings and modifying molecular structures to create nylon fibers that repel water while maintaining breathability and durability. These breakthroughs are set to expand nylon's applications in outdoor gear, medical textiles, and high-performance industrial fabrics.

Moisture Absorption vs Water Resistance Infographic

materialdif.com

materialdif.com