Nylon reinforcement offers significantly higher tensile strength and durability compared to unreinforced nylon, making it ideal for applications requiring enhanced mechanical performance. Reinforced nylon incorporates additives like glass fibers that improve stiffness, wear resistance, and thermal stability, whereas unreinforced nylon is more flexible but less resistant to impact and abrasion. Choosing reinforced nylon ensures better long-term reliability in demanding environments, while unreinforced nylon suits less structurally critical components.

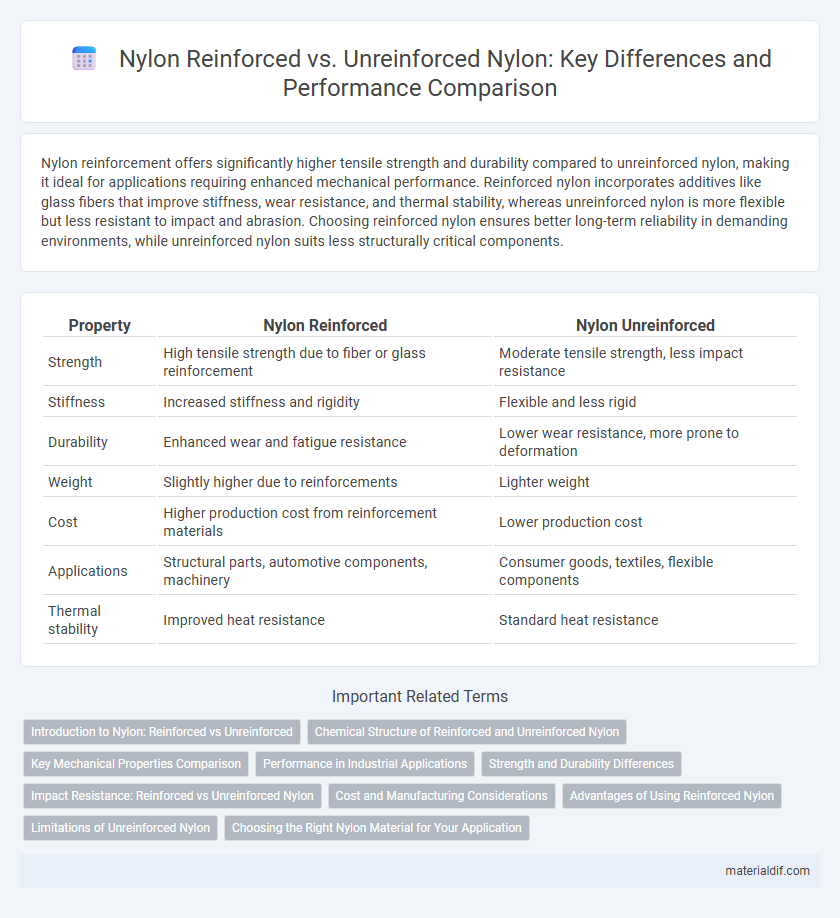

Table of Comparison

| Property | Nylon Reinforced | Nylon Unreinforced |

|---|---|---|

| Strength | High tensile strength due to fiber or glass reinforcement | Moderate tensile strength, less impact resistance |

| Stiffness | Increased stiffness and rigidity | Flexible and less rigid |

| Durability | Enhanced wear and fatigue resistance | Lower wear resistance, more prone to deformation |

| Weight | Slightly higher due to reinforcements | Lighter weight |

| Cost | Higher production cost from reinforcement materials | Lower production cost |

| Applications | Structural parts, automotive components, machinery | Consumer goods, textiles, flexible components |

| Thermal stability | Improved heat resistance | Standard heat resistance |

Introduction to Nylon: Reinforced vs Unreinforced

Nylon reinforced with glass fibers or mineral fillers exhibits significantly enhanced tensile strength, rigidity, and dimensional stability compared to unreinforced Nylon, which offers greater flexibility and impact resistance. Reinforced Nylon is preferred in high-performance applications such as automotive components and industrial machinery where durability under stress is critical. Unreinforced Nylon suits applications requiring lightweight and machinable materials, including consumer goods and textiles.

Chemical Structure of Reinforced and Unreinforced Nylon

Nylon reinforcement incorporates materials like glass fibers or carbon fibers, which modify the polymer matrix to enhance mechanical properties while maintaining the intrinsic amide linkages in the chemical structure. Unreinforced nylon primarily consists of polyamide chains with repeating units of hexamethylene diamine and adipic acid or caprolactam, forming strong hydrogen bonds that govern its elasticity and strength. The addition of reinforcements limits polymer chain mobility, improving stiffness and thermal stability without altering the fundamental polyamide backbone.

Key Mechanical Properties Comparison

Nylon reinforcement significantly enhances tensile strength, impact resistance, and dimensional stability compared to unreinforced Nylon, which tends to exhibit lower strength and higher flexibility. Reinforced Nylon composites, often infused with glass or carbon fibers, offer improved stiffness and reduced creep under load, making them ideal for structural applications. Unreinforced Nylon performs better in applications requiring chemical resistance and wearability but lacks the mechanical robustness of its reinforced counterparts.

Performance in Industrial Applications

Nylon reinforcement significantly enhances tensile strength, wear resistance, and dimensional stability compared to unreinforced nylon, making it ideal for high-load industrial applications. Reinforced nylon composites exhibit improved thermal resistance and reduced creep under continuous stress, which extends the lifespan of components in machinery and automotive parts. Unreinforced nylon offers flexibility and ease of machining but lacks the durability required for demanding environments where reinforced variants excel.

Strength and Durability Differences

Nylon reinforcement significantly enhances strength and durability by integrating materials like glass fibers, increasing tensile strength and resistance to wear compared to unreinforced nylon. Unreinforced nylon exhibits good impact resistance and flexibility but lacks the mechanical robustness needed for heavy-duty applications. Reinforced nylon's improved thermal stability and reduced creep make it ideal for industrial use where long-term performance is critical.

Impact Resistance: Reinforced vs Unreinforced Nylon

Reinforced nylon significantly enhances impact resistance compared to unreinforced nylon due to the incorporation of glass fibers or other reinforcing materials that improve toughness and dimensional stability. Unreinforced nylon tends to absorb impact by deforming or cracking under high stress, limiting its applications in high-impact environments. The reinforced variant exhibits superior energy absorption and reduced brittleness, making it ideal for components subjected to heavy mechanical loads and shock.

Cost and Manufacturing Considerations

Nylon reinforcement significantly increases material costs due to the addition of glass or carbon fibers, but it enhances mechanical properties such as strength and durability. Manufacturing reinforced Nylon requires specialized equipment and longer processing times to ensure proper fiber distribution and adhesion. Unreinforced Nylon offers lower production costs and simpler molding processes, making it suitable for applications with less stringent performance requirements.

Advantages of Using Reinforced Nylon

Reinforced nylon exhibits significantly higher strength and durability compared to unreinforced nylon, making it ideal for demanding applications in automotive and industrial sectors. The addition of glass fibers or carbon fibers enhances its resistance to wear, heat, and chemical exposure, improving performance under mechanical stress. This composite structure also reduces deformation and extends the material's lifespan, offering superior dimensional stability for precision components.

Limitations of Unreinforced Nylon

Unreinforced nylon exhibits significant limitations in mechanical strength and dimensional stability, making it less suitable for high-stress applications. It tends to absorb moisture, leading to increased swelling and reduced hardness, which compromises performance over time. In contrast, nylon reinforcement with glass or carbon fibers enhances rigidity, impact resistance, and thermal stability, overcoming these inherent weaknesses.

Choosing the Right Nylon Material for Your Application

Nylon reinforcement significantly enhances mechanical properties such as tensile strength, impact resistance, and dimensional stability compared to unreinforced nylon, making it ideal for high-stress applications. Unreinforced nylon offers better flexibility, chemical resistance, and ease of machining, suitable for components requiring intricate shapes and lower load-bearing. Assessing application requirements like load, environmental exposure, and precision helps determine whether reinforced or unreinforced nylon provides optimal performance and durability.

Nylon reinforcement vs Nylon unreinforced Infographic

materialdif.com

materialdif.com