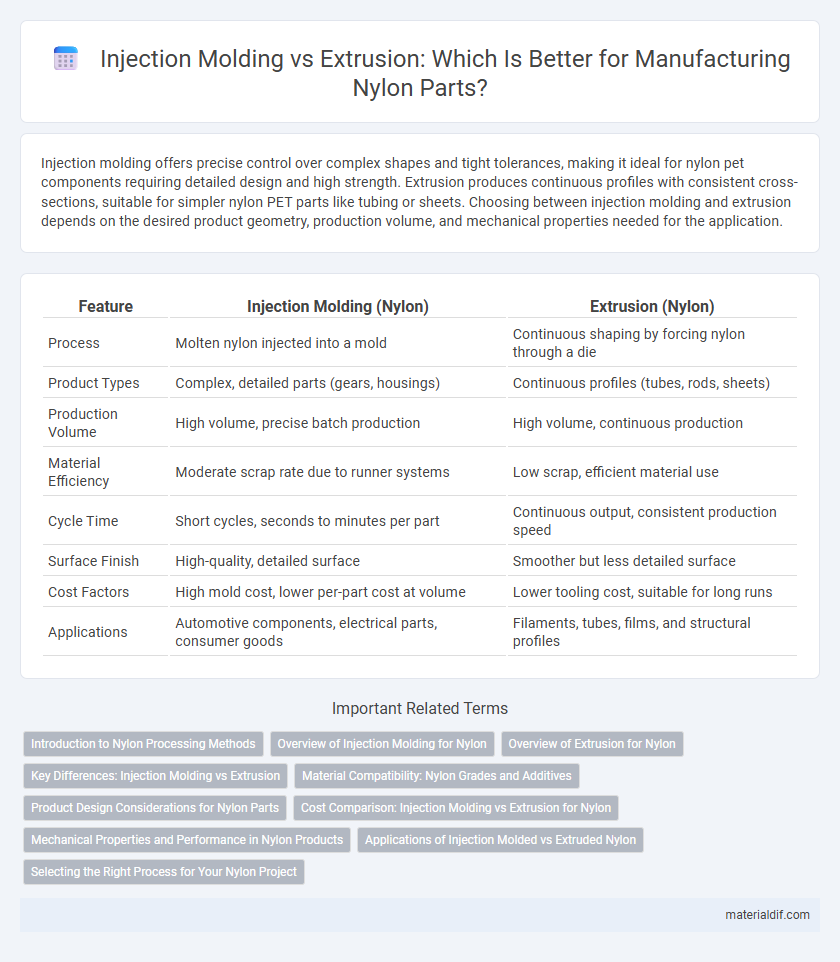

Injection molding offers precise control over complex shapes and tight tolerances, making it ideal for nylon pet components requiring detailed design and high strength. Extrusion produces continuous profiles with consistent cross-sections, suitable for simpler nylon PET parts like tubing or sheets. Choosing between injection molding and extrusion depends on the desired product geometry, production volume, and mechanical properties needed for the application.

Table of Comparison

| Feature | Injection Molding (Nylon) | Extrusion (Nylon) |

|---|---|---|

| Process | Molten nylon injected into a mold | Continuous shaping by forcing nylon through a die |

| Product Types | Complex, detailed parts (gears, housings) | Continuous profiles (tubes, rods, sheets) |

| Production Volume | High volume, precise batch production | High volume, continuous production |

| Material Efficiency | Moderate scrap rate due to runner systems | Low scrap, efficient material use |

| Cycle Time | Short cycles, seconds to minutes per part | Continuous output, consistent production speed |

| Surface Finish | High-quality, detailed surface | Smoother but less detailed surface |

| Cost Factors | High mold cost, lower per-part cost at volume | Lower tooling cost, suitable for long runs |

| Applications | Automotive components, electrical parts, consumer goods | Filaments, tubes, films, and structural profiles |

Introduction to Nylon Processing Methods

Injection molding of nylon enables the production of complex, high-strength components with tight tolerances by forcing molten nylon into detailed molds under high pressure. In contrast, extrusion processes push melted nylon through a shaped die to create continuous profiles like rods, tubes, or films with consistent cross-sections. Each method offers distinct advantages for nylon processing, balancing precision, production speed, and application-specific requirements.

Overview of Injection Molding for Nylon

Injection molding for nylon involves melting nylon pellets and injecting the molten polymer into precision-machined molds, enabling the production of complex, high-strength parts with excellent dimensional accuracy. This process is well-suited for manufacturing components such as gears, housings, and automotive parts, where nylon's durability and chemical resistance are essential. Injection molding provides superior surface finish and repeatability compared to extrusion, making it ideal for high-volume, detailed nylon parts.

Overview of Extrusion for Nylon

Extrusion for nylon involves melting and forcing the polymer through a die to create continuous shapes such as fibers, tubes, and sheets. This process provides excellent control over the shape and thickness of the final product while enabling high production rates and consistent material properties. Compared to injection molding, extrusion is more suitable for producing long, uniform profiles and is widely used in applications requiring durable nylon films and filaments.

Key Differences: Injection Molding vs Extrusion

Injection molding of nylon involves melting the polymer and injecting it into a mold to create precise, complex shapes with high dimensional accuracy and surface finish. Extrusion of nylon continuously forces melted material through a die to produce long, uniform profiles such as rods, tubes, or sheets, emphasizing consistent cross-sectional geometry. Key differences include cycle time, with injection molding offering rapid production of discrete parts versus extrusion's steady output of continuous lengths, and the complexity of shapes achievable, favoring injection molding for intricate designs and extrusion for simpler, uniform sections.

Material Compatibility: Nylon Grades and Additives

Nylon injection molding offers compatibility with higher viscosity grades and allows precise incorporation of additives such as glass fibers and impact modifiers, enhancing mechanical strength and thermal resistance. In contrast, nylon extrusion accommodates a broader range of molecular weights but requires careful control of heat stabilization additives to prevent degradation during continuous processing. Selecting the appropriate nylon grade and additive package is crucial for optimizing performance based on the distinct thermal and shear conditions inherent in injection molding versus extrusion.

Product Design Considerations for Nylon Parts

Injection molding offers precise control over complex nylon part geometries, enabling high production volumes with tight tolerances and smooth surface finishes. Extrusion is ideal for continuous nylon profiles, such as tubes and sheets, where uniform cross-sections and dimensional consistency are essential. Design considerations for nylon parts emphasize selecting injection molding for intricate shapes and extrusion for long, uniform profiles to optimize mechanical properties and production efficiency.

Cost Comparison: Injection Molding vs Extrusion for Nylon

Injection molding for Nylon typically involves higher initial costs due to expensive molds and setup but offers lower per-part costs for large production volumes, making it cost-effective for mass manufacturing. Extrusion presents lower startup expenses with simpler tooling, ideal for continuous profiles or tubing, but unit costs may increase with production complexity or small batch sizes. Evaluating production volume and part design is critical to determining which method yields the best cost efficiency for Nylon applications.

Mechanical Properties and Performance in Nylon Products

Injection molding of nylon results in parts with high dimensional accuracy, superior surface finish, and enhanced mechanical properties such as increased tensile strength and impact resistance, making it ideal for complex, high-performance components. Extrusion of nylon, while efficient for producing continuous profiles like rods or tubes, typically yields materials with more uniform mechanical properties but lower strength and surface detail compared to molded parts. The choice between injection molding and extrusion directly affects nylon product performance, with molding preferred for intricate designs requiring precise mechanical characteristics and extrusion suited for simpler, consistent shapes.

Applications of Injection Molded vs Extruded Nylon

Injection molded nylon is ideal for complex, precision parts such as gears, automotive components, and electrical housings where detailed shapes and tight tolerances are critical. Extruded nylon is commonly used for producing continuous profiles like rods, tubes, and sheets, which serve structural, mechanical, and assembly applications. The choice between injection molding and extrusion depends on part geometry, production volume, and functional requirements in industries including automotive, electrical, and consumer goods.

Selecting the Right Process for Your Nylon Project

Injection molding offers precise control and complex shape creation for nylon parts, making it ideal for high-volume production and intricate designs. Extrusion excels in producing continuous profiles like tubes and sheets, providing uniform cross-sections suited for applications requiring consistent dimensions. Choosing between injection molding and extrusion depends on project specifications such as part complexity, production volume, and design requirements for nylon components.

Injection Molding vs Extrusion (for Nylon) Infographic

materialdif.com

materialdif.com