Nylon exhibits moderate moisture absorption, allowing it to retain some water vapor, which can increase comfort by wicking sweat away from the skin. However, its water resistance is relatively limited compared to synthetic fabrics treated for waterproofing, causing it to absorb water during heavy exposure. This balance makes nylon suitable for lightweight, breathable pet gear but less ideal for fully waterproof applications.

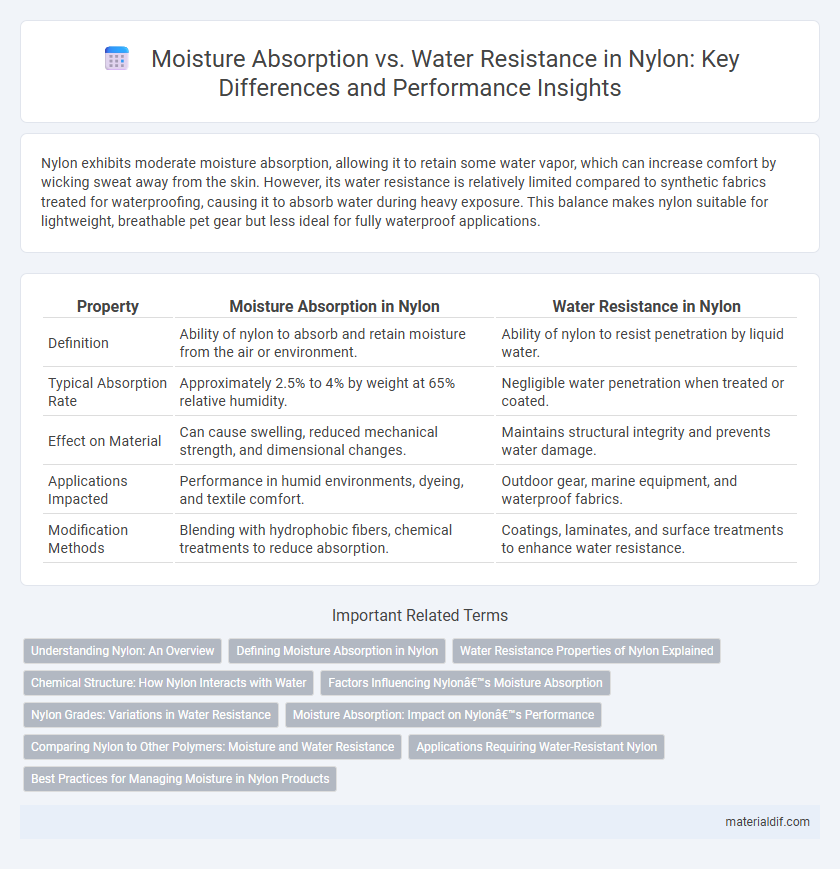

Table of Comparison

| Property | Moisture Absorption in Nylon | Water Resistance in Nylon |

|---|---|---|

| Definition | Ability of nylon to absorb and retain moisture from the air or environment. | Ability of nylon to resist penetration by liquid water. |

| Typical Absorption Rate | Approximately 2.5% to 4% by weight at 65% relative humidity. | Negligible water penetration when treated or coated. |

| Effect on Material | Can cause swelling, reduced mechanical strength, and dimensional changes. | Maintains structural integrity and prevents water damage. |

| Applications Impacted | Performance in humid environments, dyeing, and textile comfort. | Outdoor gear, marine equipment, and waterproof fabrics. |

| Modification Methods | Blending with hydrophobic fibers, chemical treatments to reduce absorption. | Coatings, laminates, and surface treatments to enhance water resistance. |

Understanding Nylon: An Overview

Nylon exhibits moderate moisture absorption, typically absorbing around 4% to 7% of its weight in water, which affects its dimensional stability and mechanical properties. Despite this, nylon maintains notable water resistance due to its hydrophobic polymer chains, making it suitable for applications where moisture exposure occurs but water permeability needs to be minimized. Understanding the balance between nylon's moisture absorption and water resistance is crucial for optimizing its performance in textiles, industrial components, and outdoor gear.

Defining Moisture Absorption in Nylon

Moisture absorption in nylon refers to the polymer's ability to absorb water vapor from the surrounding environment, typically quantified as a percentage of weight gain under specific humidity and temperature conditions. Nylon fibers can absorb up to 4-9% of their weight in moisture, impacting mechanical properties such as tensile strength, dimensional stability, and flexibility. This hygroscopic behavior distinguishes moisture absorption from water resistance, which relates to the material's ability to repel liquid water rather than its affinity for vapor absorption.

Water Resistance Properties of Nylon Explained

Nylon exhibits notable water resistance due to its hydrophobic polymer chains, which repel water molecules and reduce moisture absorption. This synthetic material maintains structural integrity and strength even in humid or wet conditions, making it ideal for outdoor gear and industrial applications. Its water resistance is enhanced through surface treatments and coatings, further improving durability and performance in moisture-prone environments.

Chemical Structure: How Nylon Interacts with Water

Nylon's chemical structure features amide groups that form hydrogen bonds with water molecules, leading to moderate moisture absorption. This interaction allows nylon to absorb about 4% to 5% of its weight in water, impacting its mechanical properties and dimensional stability. Despite this hygroscopic nature, the polymer chains' crystallinity provides intrinsic water resistance, preventing excessive water penetration and maintaining nylon's durability in humid environments.

Factors Influencing Nylon’s Moisture Absorption

Nylon's moisture absorption is primarily influenced by its molecular structure, environmental humidity, and temperature conditions. The presence of amide groups in nylon's polymer chains attracts water molecules, increasing its moisture uptake, while crystallinity level affects how much water is absorbed; higher crystallinity typically reduces moisture absorption. Although nylon exhibits significant moisture absorption, its inherent water resistance can be enhanced through surface treatments and coatings to improve durability in wet environments.

Nylon Grades: Variations in Water Resistance

Nylon grades such as Nylon 6 and Nylon 6,6 exhibit variations in water resistance due to differences in their molecular structure, impacting moisture absorption rates significantly. Nylon 6,6 typically offers better water resistance and lower moisture absorption compared to Nylon 6, making it more suitable for applications requiring enhanced durability in humid environments. Specific modifications and coatings further enhance these grades, tailoring water resistance properties for industrial or consumer products.

Moisture Absorption: Impact on Nylon’s Performance

Nylon exhibits a moisture absorption rate of approximately 4% to 5%, which affects its mechanical properties and dimensional stability. Increased moisture content can lead to a reduction in tensile strength and stiffness, impacting the durability and performance of nylon-based products. Understanding nylon's hygroscopic nature is crucial for applications requiring precise dimensional tolerances and consistent mechanical behavior in humid environments.

Comparing Nylon to Other Polymers: Moisture and Water Resistance

Nylon exhibits higher moisture absorption compared to polymers like polyester and polypropylene, absorbing up to 4% of its weight in water, which can affect its mechanical properties and dimensional stability. In contrast, polypropylene and polyester have significantly lower moisture absorption rates, enhancing their water resistance and making them more suitable for applications where exposure to wet environments is critical. Despite its moisture uptake, nylon offers better abrasion resistance and durability than many other polymers, balancing water resistance limitations with mechanical performance.

Applications Requiring Water-Resistant Nylon

Nylon exhibits low moisture absorption compared to many other synthetic fibers, making it suitable for applications requiring water resistance such as outdoor gear, marine equipment, and protective clothing. Its molecular structure limits water uptake, preserving fabric strength and durability in humid or wet conditions. Water-resistant nylon enhances performance and extends the lifespan of products exposed to rain, sweat, or splashes.

Best Practices for Managing Moisture in Nylon Products

Nylon exhibits moderate moisture absorption, typically ranging from 2-4%, which can impact its mechanical properties and dimensional stability. To enhance water resistance, treatments like hydrophobic coatings and specialized finishes are applied, reducing water uptake and improving durability. Best practices for managing moisture in nylon products include controlled conditioning environments, use of moisture barriers in packaging, and selecting resin grades with lower moisture affinity.

Moisture Absorption vs Water Resistance (in Nylon) Infographic

materialdif.com

materialdif.com