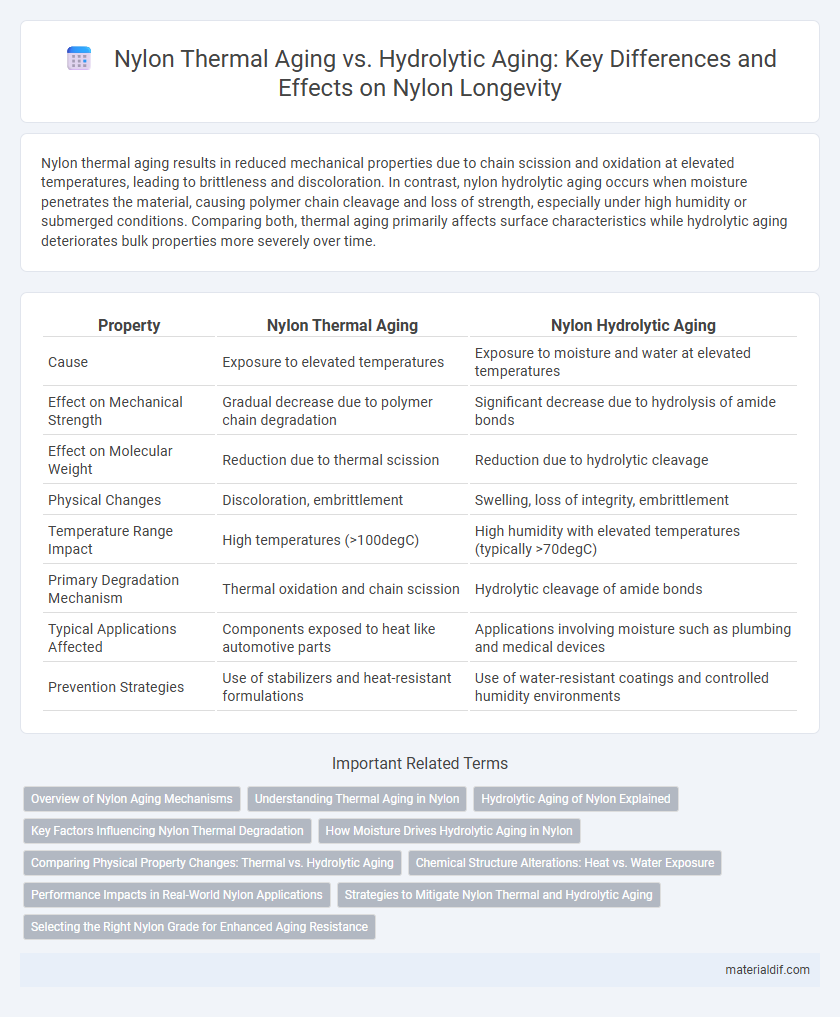

Nylon thermal aging results in reduced mechanical properties due to chain scission and oxidation at elevated temperatures, leading to brittleness and discoloration. In contrast, nylon hydrolytic aging occurs when moisture penetrates the material, causing polymer chain cleavage and loss of strength, especially under high humidity or submerged conditions. Comparing both, thermal aging primarily affects surface characteristics while hydrolytic aging deteriorates bulk properties more severely over time.

Table of Comparison

| Property | Nylon Thermal Aging | Nylon Hydrolytic Aging |

|---|---|---|

| Cause | Exposure to elevated temperatures | Exposure to moisture and water at elevated temperatures |

| Effect on Mechanical Strength | Gradual decrease due to polymer chain degradation | Significant decrease due to hydrolysis of amide bonds |

| Effect on Molecular Weight | Reduction due to thermal scission | Reduction due to hydrolytic cleavage |

| Physical Changes | Discoloration, embrittlement | Swelling, loss of integrity, embrittlement |

| Temperature Range Impact | High temperatures (>100degC) | High humidity with elevated temperatures (typically >70degC) |

| Primary Degradation Mechanism | Thermal oxidation and chain scission | Hydrolytic cleavage of amide bonds |

| Typical Applications Affected | Components exposed to heat like automotive parts | Applications involving moisture such as plumbing and medical devices |

| Prevention Strategies | Use of stabilizers and heat-resistant formulations | Use of water-resistant coatings and controlled humidity environments |

Overview of Nylon Aging Mechanisms

Nylon thermal aging primarily involves oxidative degradation, where exposure to heat causes polymer chain scission and cross-linking, leading to embrittlement and reduced mechanical properties. Hydrolytic aging occurs when moisture penetrates the material, breaking amide bonds and resulting in polymer chain cleavage, which significantly decreases tensile strength and elongation. Both mechanisms degrade Nylon's performance but differ in environmental triggers and molecular breakdown processes.

Understanding Thermal Aging in Nylon

Thermal aging in nylon causes molecular chain scission and cross-linking, leading to reduced tensile strength and increased brittleness over time. Exposure to elevated temperatures accelerates oxidation processes, which degrade the polymer's mechanical properties and dimensional stability. This contrasts with nylon hydrolytic aging, where moisture-induced hydrolysis breaks amide bonds, predominantly causing loss of molecular weight and altered crystallinity.

Hydrolytic Aging of Nylon Explained

Hydrolytic aging of nylon involves the chemical breakdown of polymer chains due to prolonged exposure to moisture and elevated temperatures, leading to significant reductions in mechanical strength and elongation properties. This process is accelerated in environments with high humidity and heat, causing nylon to absorb water molecules that catalyze hydrolysis of amide bonds in the polymer backbone. Compared to thermal aging, which primarily results from heat-induced oxidation and chain scission, hydrolytic aging more severely impairs nylon's structural integrity by disrupting molecular weight and crystallinity through moisture-induced degradation.

Key Factors Influencing Nylon Thermal Degradation

Nylon thermal degradation is primarily influenced by temperature, oxygen presence, and exposure duration, leading to oxidation and chain scission that weaken mechanical properties, while hydrolytic aging involves moisture-induced polymer chain cleavage affecting dimensional stability. Thermal aging causes changes such as discoloration, embrittlement, and loss of tensile strength due to oxidative reactions, whereas hydrolytic aging results in hydrolysis of amide bonds under humid or aqueous conditions, significantly impacting molecular weight and surface morphology. Understanding the interplay of heat, oxygen, and moisture is crucial for predicting nylon's lifespan in high-temperature or humid environments.

How Moisture Drives Hydrolytic Aging in Nylon

Moisture significantly accelerates hydrolytic aging in Nylon by penetrating its polymer matrix and catalyzing the cleavage of amide bonds, leading to chain scission and reduced molecular weight. Unlike thermal aging, which primarily causes oxidation and embrittlement at elevated temperatures, hydrolytic aging involves chemical degradation driven by water molecules breaking polymer chains. This moisture-induced hydrolysis results in decreased mechanical properties and altered crystallinity, critically affecting the long-term durability of Nylon in humid environments.

Comparing Physical Property Changes: Thermal vs. Hydrolytic Aging

Nylon exhibits distinct physical property changes under thermal aging versus hydrolytic aging, with thermal aging primarily causing embrittlement and increased stiffness due to oxidation and chain scission. Hydrolytic aging leads to significant molecular weight reduction and loss of mechanical strength as water molecules cleave amide bonds, resulting in decreased tensile strength and elongation. Thermal aging generally affects surface hardness and color, whereas hydrolytic aging critically impairs structural integrity and dimensional stability.

Chemical Structure Alterations: Heat vs. Water Exposure

Nylon's thermal aging primarily induces chain scission and cross-linking within the polyamide chains due to elevated temperatures, resulting in reduced molecular weight and altered crystallinity. In contrast, hydrolytic aging involves the cleavage of amide bonds through water molecules, causing significant hydrolysis that breaks down the polymer backbone and leads to a decrease in mechanical properties. These distinct chemical structure alterations underline the difference between heat-induced oxidation and moisture-driven hydrolysis mechanisms in nylon degradation.

Performance Impacts in Real-World Nylon Applications

Nylon thermal aging leads to chain scission and oxidation, causing brittleness and reduced tensile strength, which significantly impacts long-term durability in automotive and electrical components. Hydrolytic aging, driven by moisture absorption and hydrolysis, results in reduced molecular weight and loss of mechanical properties, critically affecting performance in humid or water-exposed environments like marine and textile industries. Real-world applications must consider these degradation mechanisms to optimize material selection and ensure reliable performance under varying thermal and moisture conditions.

Strategies to Mitigate Nylon Thermal and Hydrolytic Aging

Nylon thermal aging primarily causes oxidation and chain scission, while hydrolytic aging leads to polymer chain hydrolysis and reduced mechanical strength. Strategies to mitigate these effects include incorporating antioxidants and thermal stabilizers to enhance resistance against thermal degradation, and using moisture scavengers or applying surface coatings to protect against hydrolytic attack. Optimizing processing conditions and employing copolymerization techniques also improve Nylon's durability under both thermal and hydrolytic aging environments.

Selecting the Right Nylon Grade for Enhanced Aging Resistance

Nylon thermal aging primarily involves degradation due to heat exposure, causing polymer chain scission and oxidative damage, while hydrolytic aging results from moisture-induced hydrolysis leading to molecular weight reduction and loss of mechanical properties. Selecting the right nylon grade with enhanced thermal stability, such as Nylon 6,6 with high crystallinity, offers superior resistance to heat aging, whereas grades like Nylon 6 with added stabilizers improve hydrolytic resistance by minimizing water absorption and hydrolysis effects. Optimizing the nylon grade based on the specific aging environment significantly enhances long-term durability and performance in demanding applications.

Nylon thermal aging vs Nylon hydrolytic aging Infographic

materialdif.com

materialdif.com