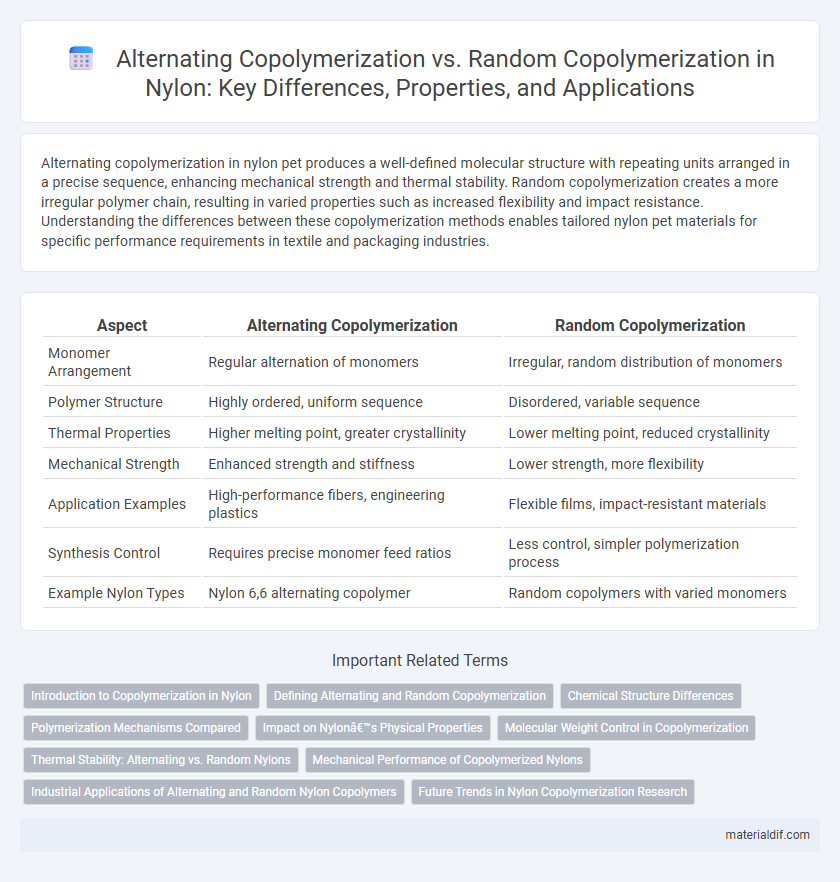

Alternating copolymerization in nylon pet produces a well-defined molecular structure with repeating units arranged in a precise sequence, enhancing mechanical strength and thermal stability. Random copolymerization creates a more irregular polymer chain, resulting in varied properties such as increased flexibility and impact resistance. Understanding the differences between these copolymerization methods enables tailored nylon pet materials for specific performance requirements in textile and packaging industries.

Table of Comparison

| Aspect | Alternating Copolymerization | Random Copolymerization |

|---|---|---|

| Monomer Arrangement | Regular alternation of monomers | Irregular, random distribution of monomers |

| Polymer Structure | Highly ordered, uniform sequence | Disordered, variable sequence |

| Thermal Properties | Higher melting point, greater crystallinity | Lower melting point, reduced crystallinity |

| Mechanical Strength | Enhanced strength and stiffness | Lower strength, more flexibility |

| Application Examples | High-performance fibers, engineering plastics | Flexible films, impact-resistant materials |

| Synthesis Control | Requires precise monomer feed ratios | Less control, simpler polymerization process |

| Example Nylon Types | Nylon 6,6 alternating copolymer | Random copolymers with varied monomers |

Introduction to Copolymerization in Nylon

Alternating copolymerization in nylon production involves the regular repetition of two different monomers, such as hexamethylene diamine and adipic acid, resulting in a highly ordered polymer chain with consistent properties. Random copolymerization incorporates varying ratios of monomers in an irregular sequence, which can enhance impact resistance and flexibility by disrupting crystalline regions. Understanding the differences in copolymerization methods is crucial for tailoring nylon's mechanical strength, thermal stability, and chemical resistance for specific industrial applications.

Defining Alternating and Random Copolymerization

Alternating copolymerization involves the regular, repeating sequence of two distinct monomers, resulting in a polymer with a highly ordered structure. Random copolymerization features a irregular distribution of monomers along the polymer chain, producing materials with varied properties due to the stochastic placement of monomer units. In nylon synthesis, alternating copolymers promote enhanced crystallinity and mechanical strength, while random copolymers offer greater flexibility and impact resistance.

Chemical Structure Differences

Alternating copolymerization in nylon involves a precise sequence where two different monomers alternate regularly along the polymer chain, creating a highly ordered chemical structure with consistent repeating units. Random copolymerization results in an irregular arrangement of monomers, producing a polymer with a varied chemical composition and less predictable properties due to the stochastic distribution of monomer units. These structural variations significantly impact the thermal, mechanical, and chemical resistance characteristics of nylon materials.

Polymerization Mechanisms Compared

Alternating copolymerization of nylon involves the regular, repeating incorporation of two different monomers, such as hexamethylene diamine and adipic acid, resulting in highly ordered polymer chains with predictable properties. Random copolymerization introduces monomers in a non-sequential, stochastic manner, producing polymers with varied monomer distribution and less uniform physical characteristics. The polymerization mechanism in alternating copolymerization relies on strong monomer affinity and stoichiometric balance, whereas random copolymerization depends on monomer reactivity ratios and feed composition, impacting molecular architecture and performance.

Impact on Nylon’s Physical Properties

Alternating copolymerization in nylon produces a highly regular polymer chain, resulting in enhanced crystallinity, increased tensile strength, and improved thermal stability. Random copolymerization introduces irregularities in the polymer sequence, leading to lower crystallinity, increased flexibility, and reduced melting temperature. These differences directly impact nylon's mechanical properties, with alternating copolymers exhibiting superior durability and random copolymers offering better impact resistance and elasticity.

Molecular Weight Control in Copolymerization

Alternating copolymerization of nylon allows for more precise molecular weight control due to the predictable arrangement of monomer units, resulting in uniform chain lengths and improved polymer properties. In contrast, random copolymerization produces a distribution of molecular weights because of the irregular incorporation of monomers, leading to less consistent polymer performance. Optimizing molecular weight during nylon copolymerization directly impacts mechanical strength, thermal stability, and processability of the final material.

Thermal Stability: Alternating vs. Random Nylons

Alternating copolymerization in nylons produces polymers with highly regular molecular structures, resulting in enhanced thermal stability and higher melting points compared to random copolymerization. Random nylons, characterized by irregular monomer sequences, exhibit reduced crystallinity, leading to lower thermal resistance and decreased thermal decomposition temperatures. The controlled sequence distribution in alternating nylons facilitates stronger intermolecular hydrogen bonding, directly improving their thermal decomposition resistance and mechanical performance at elevated temperatures.

Mechanical Performance of Copolymerized Nylons

Alternating copolymerization in nylons creates a highly regular polymer chain structure, resulting in enhanced crystallinity and superior tensile strength compared to random copolymerization. Random copolymerized nylons exhibit reduced crystallinity due to irregular monomer distribution, leading to improved impact resistance and flexibility but lower mechanical stiffness. Optimizing the ratio of alternating to random sequences tailors the balance between strength and toughness for specific engineering applications.

Industrial Applications of Alternating and Random Nylon Copolymers

Alternating copolymerization of nylon produces materials with consistent monomer sequence and enhanced mechanical strength, making them ideal for high-performance industrial applications such as automotive parts and electrical insulation. Random copolymerization results in nylons with varied monomer distribution, offering improved impact resistance and flexibility suited for textile fibers, packaging films, and consumer goods. Industrial use of alternating nylon copolymers often emphasizes thermal stability and toughness, while random nylon copolymers are preferred for applications requiring elasticity and enhanced processability.

Future Trends in Nylon Copolymerization Research

Future trends in nylon copolymerization research emphasize enhancing material properties through precise control of alternating copolymerization, which enables the design of nylons with improved mechanical strength and thermal stability. Advances in catalysis and polymerization techniques are driving the development of sequence-controlled nylons, overcoming the limitations of random copolymerization that often results in heterogeneous polymer chains. Emerging research aims to optimize molecular architecture at the nanoscale, promoting sustainable and high-performance nylon materials for applications in automotive, aerospace, and biomedical industries.

Alternating copolymerization vs Random copolymerization Infographic

materialdif.com

materialdif.com