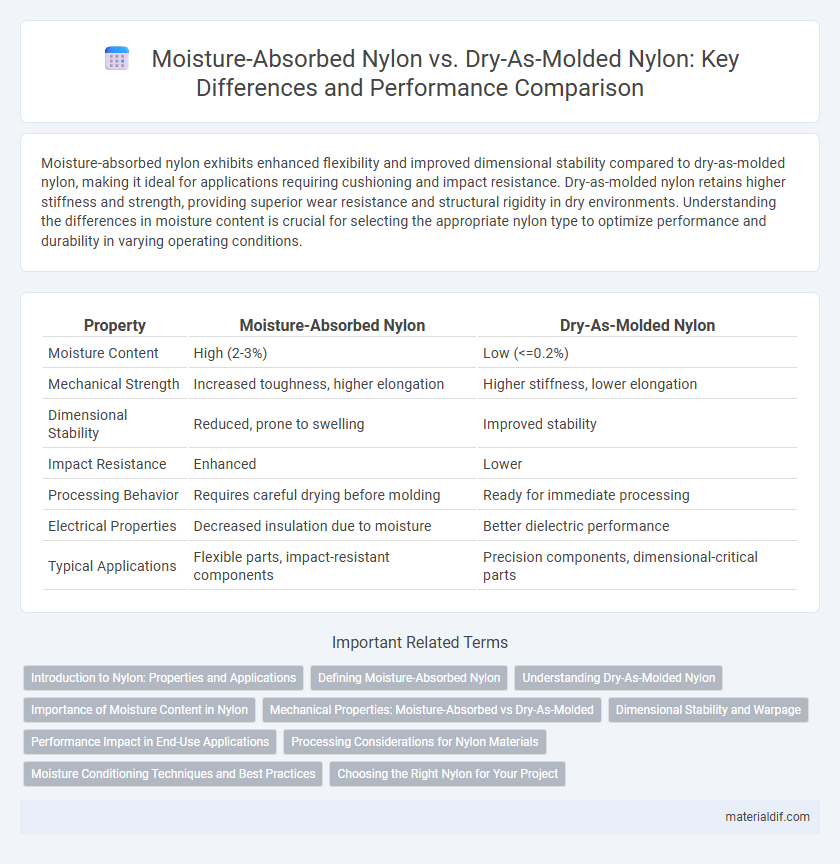

Moisture-absorbed nylon exhibits enhanced flexibility and improved dimensional stability compared to dry-as-molded nylon, making it ideal for applications requiring cushioning and impact resistance. Dry-as-molded nylon retains higher stiffness and strength, providing superior wear resistance and structural rigidity in dry environments. Understanding the differences in moisture content is crucial for selecting the appropriate nylon type to optimize performance and durability in varying operating conditions.

Table of Comparison

| Property | Moisture-Absorbed Nylon | Dry-As-Molded Nylon |

|---|---|---|

| Moisture Content | High (2-3%) | Low (<=0.2%) |

| Mechanical Strength | Increased toughness, higher elongation | Higher stiffness, lower elongation |

| Dimensional Stability | Reduced, prone to swelling | Improved stability |

| Impact Resistance | Enhanced | Lower |

| Processing Behavior | Requires careful drying before molding | Ready for immediate processing |

| Electrical Properties | Decreased insulation due to moisture | Better dielectric performance |

| Typical Applications | Flexible parts, impact-resistant components | Precision components, dimensional-critical parts |

Introduction to Nylon: Properties and Applications

Moisture-absorbed nylon exhibits increased flexibility and reduced tensile strength compared to dry-as-molded nylon, which retains higher rigidity and dimensional stability. The hygroscopic nature of nylon significantly impacts its mechanical properties and suitability in applications such as automotive components, textiles, and industrial parts. Understanding the moisture content is crucial for optimizing performance and longevity in engineering designs utilizing nylon materials.

Defining Moisture-Absorbed Nylon

Moisture-absorbed nylon refers to nylon material that has absorbed water vapor from the surrounding environment, impacting its mechanical and electrical properties. This state occurs when nylon reaches equilibrium moisture content, typically around 2-9% depending on the type, which increases its flexibility but decreases tensile strength and dimensional stability. Understanding moisture absorption is crucial for applications requiring precise engineering tolerances and consistent material performance.

Understanding Dry-As-Molded Nylon

Dry-as-molded nylon refers to nylon resin that has not absorbed moisture prior to processing, maintaining its original mechanical and electrical properties. This state is critical for applications requiring high strength, stability, and consistent molding results, as absorbed moisture can lead to hydrolytic degradation during molding. Proper drying of nylon resin ensures optimal performance, reduced defects, and enhanced durability in the final product.

Importance of Moisture Content in Nylon

Moisture content in nylon significantly affects its mechanical properties, dimensional stability, and processing behavior. Moisture-absorbed nylon demonstrates improved flexibility and impact resistance due to plasticization, while dry-as-molded nylon maintains higher tensile strength and stiffness but is more prone to brittleness. Controlling moisture levels is essential to optimizing nylon's performance in applications such as automotive components and industrial parts.

Mechanical Properties: Moisture-Absorbed vs Dry-As-Molded

Moisture-absorbed nylon exhibits reduced tensile strength and stiffness compared to its dry-as-molded counterpart due to water acting as a plasticizer within the polymer matrix. The elongation at break increases in moisture-absorbed nylon, enhancing flexibility but compromising dimensional stability under load. Dry-as-molded nylon retains higher hardness and impact resistance, crucial for applications requiring structural integrity and wear resistance.

Dimensional Stability and Warpage

Moisture-absorbed nylon exhibits reduced dimensional stability compared to dry-as-molded nylon, as the absorbed water plasticizes the polymer matrix, causing swelling and increased vulnerability to warpage. Dry-as-molded nylon maintains its shape integrity better under mechanical stress due to the absence of absorbed moisture, resulting in superior dimensional accuracy and minimal deformation. Controlling moisture content in nylon during processing is critical to minimizing warpage and ensuring consistent performance in precision applications.

Performance Impact in End-Use Applications

Moisture-absorbed nylon exhibits reduced tensile strength and increased elongation, impacting dimensional stability and mechanical performance in precision engineering and automotive parts. Dry-as-molded nylon maintains higher rigidity and consistent electrical insulation properties, essential for electronic housings and structural components. The absorption of moisture alters thermal resistance, causing potential deformation and decreased wear resistance in demanding operational environments.

Processing Considerations for Nylon Materials

Moisture-absorbed nylon requires thorough drying before processing to prevent hydrolysis, which can degrade polymer chains and reduce mechanical properties. Dry-as-molded nylon maintains optimal melt viscosity and dimensional stability, enhancing surface finish and minimizing defects during molding. Proper moisture control is essential in injection molding and extrusion to ensure consistent quality and prevent issues such as voids, bubbles, or brittleness in final nylon parts.

Moisture Conditioning Techniques and Best Practices

Moisture conditioning techniques for nylon involve controlled humidity exposure to achieve optimal moisture absorption, enhancing flexibility and dimensional stability in finished products. Best practices include using standardized conditioning chambers at 50% relative humidity and 23degC for 40 hours to simulate typical usage environments. Proper moisture absorption prevents brittleness in moisture-absorbed nylon and ensures consistent mechanical properties compared to dry-as-molded nylon.

Choosing the Right Nylon for Your Project

Moisture-absorbed nylon exhibits increased flexibility and improved impact resistance due to the plasticizing effect of water molecules within its polymer structure. Dry-as-molded nylon, with low moisture content, offers higher stiffness and dimensional stability, making it ideal for precision components requiring tight tolerance control. Selecting the appropriate nylon variant depends on the application's environmental exposure and mechanical performance requirements, ensuring optimal durability and functionality.

Moisture-Absorbed Nylon vs Dry-As-Molded Nylon Infographic

materialdif.com

materialdif.com