Nylon powder coating offers superior durability and abrasion resistance compared to nylon liquid coating, making it ideal for industrial applications requiring long-lasting protection. Nylon liquid coating provides a smoother finish and better flexibility, suitable for products needing intricate detailing and varied thickness. Both coatings enhance corrosion resistance, but selecting between powder and liquid depends on the specific performance requirements and aesthetic preferences of the end product.

Table of Comparison

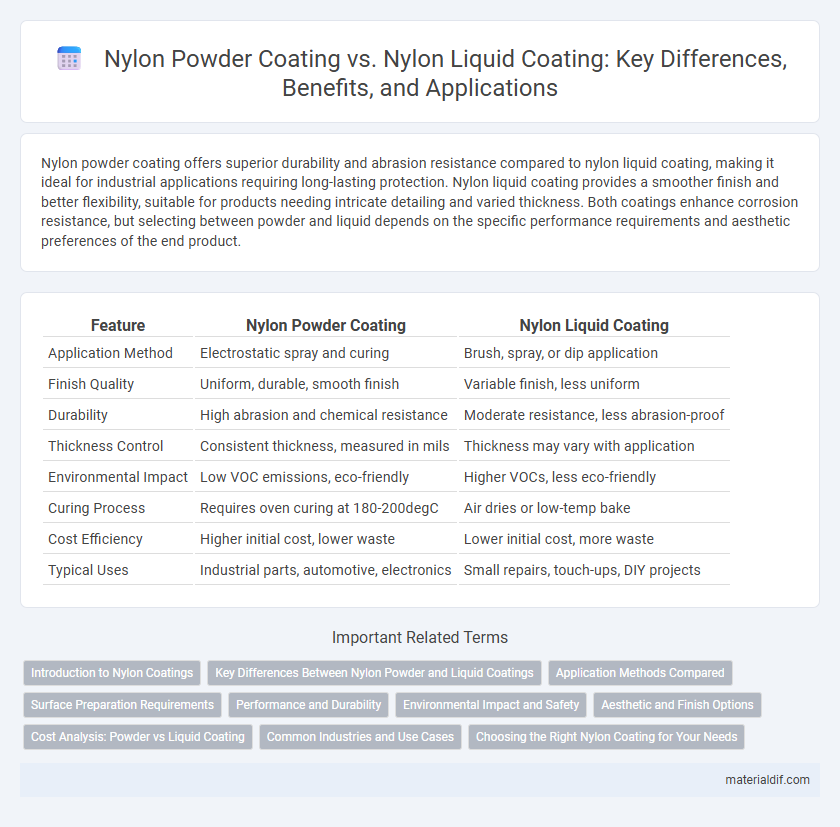

| Feature | Nylon Powder Coating | Nylon Liquid Coating |

|---|---|---|

| Application Method | Electrostatic spray and curing | Brush, spray, or dip application |

| Finish Quality | Uniform, durable, smooth finish | Variable finish, less uniform |

| Durability | High abrasion and chemical resistance | Moderate resistance, less abrasion-proof |

| Thickness Control | Consistent thickness, measured in mils | Thickness may vary with application |

| Environmental Impact | Low VOC emissions, eco-friendly | Higher VOCs, less eco-friendly |

| Curing Process | Requires oven curing at 180-200degC | Air dries or low-temp bake |

| Cost Efficiency | Higher initial cost, lower waste | Lower initial cost, more waste |

| Typical Uses | Industrial parts, automotive, electronics | Small repairs, touch-ups, DIY projects |

Introduction to Nylon Coatings

Nylon coatings are widely used for their excellent abrasion resistance, chemical stability, and durability in industrial applications. Nylon powder coating offers a dry, thermoplastic application that provides a thicker, uniform protective layer, while nylon liquid coating involves a wet application that allows for more complex shapes and finer detail coverage. Both types enhance surface protection and corrosion resistance, but the choice depends on the specific performance requirements and substrate compatibility.

Key Differences Between Nylon Powder and Liquid Coatings

Nylon powder coating offers superior durability and abrasion resistance compared to nylon liquid coating, making it ideal for heavy-use applications. Liquid nylon coatings provide better coverage on complex shapes and thinner, more uniform layers, enhancing flexibility and aesthetic appeal. The curing process differs as powder coatings require baking at high temperatures, whereas liquid coatings dry at room temperature or with minimal heat, affecting application speed and environmental considerations.

Application Methods Compared

Nylon powder coating is applied through electrostatic spraying followed by curing in an oven, providing a durable, uniform finish ideal for complex shapes and heavy-duty applications. Nylon liquid coating uses dipping, spraying, or brushing methods, offering superior control over coating thickness and better adhesion on irregular or intricate surfaces. Both methods enhance corrosion and wear resistance, but powder coating is preferred for large-scale or industrial applications due to faster processing and minimal waste.

Surface Preparation Requirements

Nylon powder coating requires a clean, dry surface free from oils, grease, and dirt, often necessitating abrasive blasting or chemical cleaning to enhance adhesion and ensure a uniform finish. Nylon liquid coating demands thorough surface degreasing and possibly light sanding to promote better bonding and smooth coverage. Both methods emphasize meticulous surface preparation to prevent coating failures and maximize durability.

Performance and Durability

Nylon powder coating offers superior abrasion resistance and a thicker, more uniform finish compared to nylon liquid coating, enhancing its durability in harsh environments. Nylon liquid coating provides excellent flexibility and conformability, making it ideal for complex shapes but may be less resistant to chipping and wear over time. For high-impact applications requiring long-lasting protection, nylon powder coating generally outperforms nylon liquid coating in overall performance and lifespan.

Environmental Impact and Safety

Nylon powder coating produces minimal volatile organic compounds (VOCs) and generates less hazardous waste compared to nylon liquid coating, making it a more environmentally friendly option. Nylon powder coatings are free from solvents and emit lower levels of harmful emissions, enhancing workplace safety by reducing inhalation risks. In contrast, nylon liquid coatings often contain solvents that pose greater environmental and health hazards due to toxic fumes and disposal challenges.

Aesthetic and Finish Options

Nylon powder coating offers a thicker, more uniform finish with excellent durability, ideal for applications requiring robust protection and a matte or textured appearance. Nylon liquid coating provides greater flexibility in color variety and gloss levels, enabling smoother, more refined surfaces suited for intricate designs. Both methods enhance corrosion resistance, but liquid coatings allow for easier touch-ups and aesthetic customization.

Cost Analysis: Powder vs Liquid Coating

Nylon powder coating generally offers lower overall costs due to reduced overspray waste and faster curing times compared to nylon liquid coating, which requires solvents and longer drying periods. While liquid nylon coatings may have a lower initial material cost, their application process often involves higher labor and environmental compliance expenses. Evaluating the total cost of ownership reveals powder coatings as a more economical choice for large-scale or repetitive nylon surface treatments.

Common Industries and Use Cases

Nylon powder coating is widely used in automotive, industrial machinery, and electrical appliances due to its excellent abrasion resistance, chemical durability, and ability to create thick, uniform layers on complex parts. Nylon liquid coating is preferred in textile manufacturing, medical devices, and food processing equipment for its superior flexibility, smooth finish, and precise application on intricate or delicate surfaces. Both coatings are valued for corrosion resistance and enhanced surface protection but differ in application methods and suitability based on industry-specific requirements.

Choosing the Right Nylon Coating for Your Needs

Nylon powder coating offers excellent durability, chemical resistance, and a smooth, uniform finish ideal for industrial applications demanding high wear resistance. Nylon liquid coating provides superior adhesion on complex geometries, allowing precise thickness control and better coverage for intricate parts. Selecting the right nylon coating depends on factors like surface complexity, environmental exposure, and desired finish quality to ensure optimal protection and performance.

Nylon Powder Coating vs Nylon Liquid Coating Infographic

materialdif.com

materialdif.com